PC-based control for process automation: New hardware and software solutions for hazardous areas

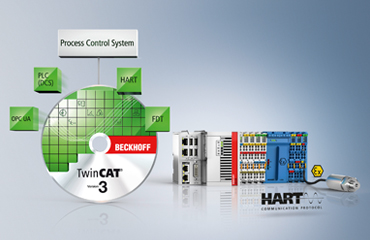

Beckhoff Automation has announced the integration of new HART protocol functionality in the company’s TwinCAT automation software and I/O system hardware. In the process industries, demands are increasing for groundbreaking and innovative automation solutions that also reduce costs. The greatest potential for optimization is opened up by implementing a universal platform that covers both industrial automation and process automation.

PC-based control from Beckhoff fits this bill by integrating process-specific protocols and interfaces, and by offering an extended range of products for hazardous areas. Full implementation of HART functionality, both in the I/O system and in the TwinCAT engineering environment, promotes simple project planning and reliable commissioning.

PC-based control from Beckhoff fits this bill by integrating process-specific protocols and interfaces, and by offering an extended range of products for hazardous areas. Full implementation of HART functionality, both in the I/O system and in the TwinCAT engineering environment, promotes simple project planning and reliable commissioning.

TwinCAT software clearly reduces development efforts in process technology because it facilitates the application of comprehensive HART functions directly from the engineering interface. In this way, the TwinCAT FDT (Field Device Tool) container enables implementation of any field device drivers (Device Type Manager, DTM). This means that an entire HART configuration can be implemented efficiently using a single software tool.

The Beckhoff CommDTM integrates the powerful TwinCAT platform into existing process control systems. With its help, the DTMs can be implemented in any FDT container. This applies to all field devices connected to the HART-capable EtherCAT Terminals. These devices can be configured and parameterized remotely in the known containers without requiring direct PLC access. As a result, system operation is simplified and reduced to the essentials. In addition, the Beckhoff OPC UA Server and Client enable secure global distribution of process data, as well as convenient system control and remote maintenance capabilities.

Explosion protection integrated into product portfolio

The new, highly compact EtherCAT Terminals in the ELX series are also HART-capable. With intrinsically safe inputs/outputs, they enable the direct integration of field devices installed in hazardous areas, Zones 0, 1 or 2, into the automation system. The reduced wiring effort and associated space savings result in integrated, cost-effective solutions for process applications. Furthermore, the new CPX series of Control Panels and Panel PCs makes the high-quality design and advanced multi-touch display technology from Beckhoff similarly available for locations subject to explosion hazards.