The AMLOK® Hydraulic Series RCH Rod Clamp has been developed to provide power-off clamping of rods and shafts. The type RCH Rod Clamps are actuated by a spring/collet mechanism and unclamped by hydraulic pressure. These rod clamps are designed to clamp components after the motion has stopped and to hold the position securely as long as the forces do not exceed the table values. For braking and pneumatic applications, contact the factory.

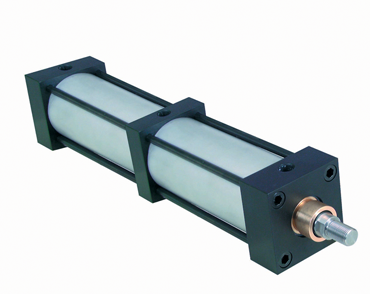

The mountings of the RCH AMLOK® Rod Clamp have been designed to apply to standard heavy-duty NFPA-style MF1 cylinders. The standard housing can be mounted to any machine structure or be custom-designed to suit your application.

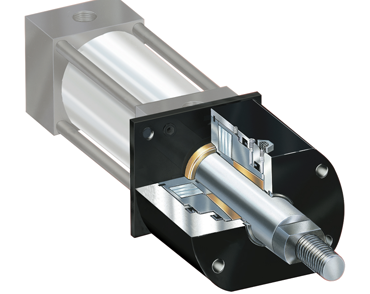

Function: The AMLOK® Rod Clamp consists of an alloy steel housing containing a special locking mechanism actuated by a set of disc springs. The clamp is unlocked when hydraulic pressure actuates a piston that compresses the disc springs, and releases the locking device.

The AMLOK® Rod Clamp consists of an alloy steel housing containing a special locking mechanism actuated by a set of disc springs. The clamp is unlocked when hydraulic pressure actuates a piston that compresses the disc springs, and releases the locking device.

Since the locking of the AMLOK® Rod Clamp is accomplished mechanically and unlocked by hydraulic pressure, loss of hydraulic pressure to the rod clamp will cause the unit to lock.

The holding force depends upon the rod diameter and the amount of hydraulic pressure (PSI) available for unclamping. The AMLOK® is preset at the factory to release at the specified hydraulic pressure. The available holding forces are listed in the chart and can be multiplied by adding additional AMLOK® clamps to the same rod. Also, special SITEMA Safety Catchers and Locking Units can be provided to suit your needs.

AMLOK® Rod Clamps are designed for locking reciprocating motions only. Special units are also available for both rotating and reciprocating motions.

Application Guidelines: When attached to cylinders, longer cylinder rods must be specified. The AMLOK® Rod Clamp requires a full rod diameter for the entire length “L” of the clamp. Add a minimum of “L” length for a Rod Extension to allow for the length of the AMLOK®.

When attached to cylinders, longer cylinder rods must be specified. The AMLOK® Rod Clamp requires a full rod diameter for the entire length “L” of the clamp. Add a minimum of “L” length for a Rod Extension to allow for the length of the AMLOK®.

The contact surfaces and bores to which the AMLOK® is clamped must be square and concentric to each other to avoid binding of the rod or excess wear. AMLOK® Rod Clamps can be an integral part of your housing. We can provide mating components for your special applications.

The AMLOK® is designed for zero side loads. When side loads are acting on the cylinder rod, make sure that the rod is guided sufficiently in bearings to avoid side loads on the locking mechanism. This is especially important at higher cylinder rod speeds to avoid overheating the clamping device due to excessive friction with the rod.

Each AMLOK® Rod Clamp is tested by Advanced Machine. These test results are available upon request.

About Advanced Machine & Engineering Co.:

Advanced Machine & Engineering Co., is a manufacturer located in Rockford, IL, serving the Machine Tool Industry with precision components and accessories, including spindle interface components, workholding devices, and, through our sister company, Hennig, machine enclosures, chip removal and filtration systems. The Fluid Power – Safety markets are served with cylinder rod locks and safety catcher devises; and the Production Saw market with our AmSaw® carbide saw machines and Speedcut blade products. AME has manufacturing partners and customers around the world and across the U.S.

For more information, please visit:

www.ame.com

Or contact:

info@ame.com

Hennig, Inc. design and produces custom machine protection and chip/coolant management products for state-of-the-art machine tools. Hennig products are designed to protect against corrosion, debris and common workplace contaminants. Manufacturing facilities are located in the U.S., Germany, Brazil, India, Japan, France and South Korea. Repair centers are located in Machesney Park, IL; Chandler, OK; Livonia, MI; Blue Ash, OH; Mexico City, Mexico and Saltillo, Mexico.

For more information, please visit:

www.hennigworldwide.com