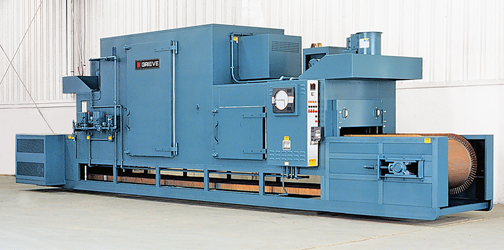

No. 867 is an 850ºF (454ºC), gas-heated belt conveyor oven from Grieve, currently used for production heat treating of metal springs at the customer’s facility. Workspace dimensions of this oven measure 36” W x 18’ D x 15” H. 800,000 BTU/HR are installed in a natural gas burner to heat the oven chamber, while a 12,500 CFM, 10-HP stainless steel recirculating blower provides vertical downward airflow to the workload.

The oven travel comprises a 3’ long open belt loading zone, 18’ long insulated heat zone with recirculated airflow, 3’ long open belt unloading zone and a 30” wide, Type 304 stainless steel woven wire conveyor belt with 3” high flex plate edges, driven by a ½-HP motor v-belt drive, variable from 1-19 IPM.

This Grieve belt conveyor oven features 7” thick insulated walls, aluminized steel exterior and interior, exhaust hoods over each end equipped with a 12” diameter tubeaxial fan, driven by a ½-HP motor, plus all safety equipment required by IRI, FM and NFPA Standard 86 for gas-heated equipment, including a 650 CFM, ½-HP powered forced exhauster.

Controls on No. 867 include a digital indicating temperature controller and 10” diameter circular chart recorder.

For more information, please visit:

www.grievecorp.com

or contact:

sales@grievecorp.com

Attention: Frank Calabrese