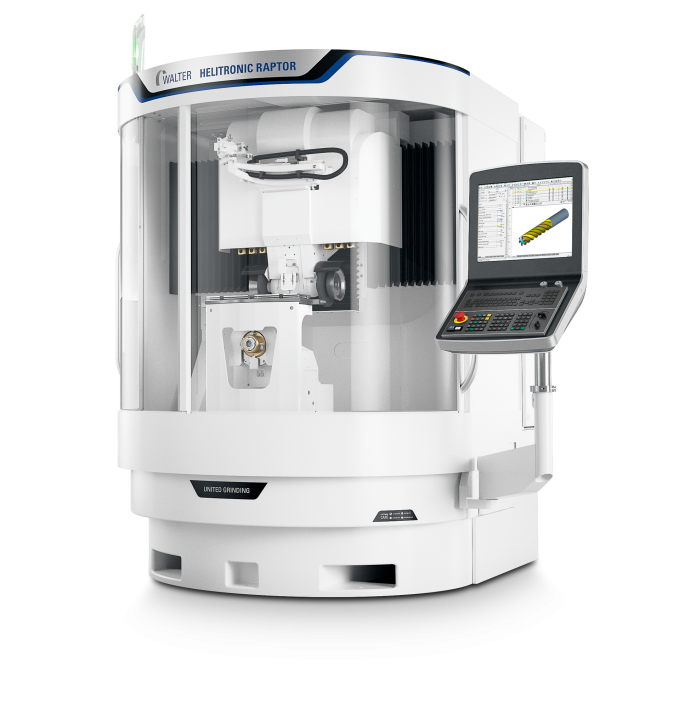

The new WALTER HELITRONIC RAPTOR from UNITED GRINDING Group is a flexible, cost-effective tool grinding solution. Created for the grinding and re-sharpening of rotationally symmetrical tools for the metal and wood industries, the new HELITRONIC RAPTOR offers both automation-ready flexibility and an economical, universal design for all-around tool grinding excellence.

Developed with the re-sharpening sector of the rotationally symmetrical tool market in mind, the WALTER HELITRONIC RAPTOR is particularly well-suited for shops that do not require features such as automatic tool support systems or automatic grinding wheel changers, but still need a high degree of flexibility in the working area for diverse types of tools. The new machine ensures that manufacturers have access to WALTER quality with exactly the features they need for part-production and re-sharpening success.

The HELITRONIC RAPTOR has a 15.4 hp (11.5 kW) spindle and a work envelope that can accommodate tools up to 12.6″ (320 mm) in diameter and 11.0″ (280 mm) in length, including end face operations. For the utmost in tool grinding efficiency, from tool design to part production as well as re-sharpening, the machine uses WALTER HELITRONIC TOOL STUDIO.

The HELITRONIC RAPTOR has a 15.4 hp (11.5 kW) spindle and a work envelope that can accommodate tools up to 12.6″ (320 mm) in diameter and 11.0″ (280 mm) in length, including end face operations. For the utmost in tool grinding efficiency, from tool design to part production as well as re-sharpening, the machine uses WALTER HELITRONIC TOOL STUDIO.

In addition to its low-vibration gray cast iron frame and gantry-type construction, the HELITRONIC RAPTOR is designed to accommodate a range of options, including top loaders with up to 500-tool capacities integrated in the working area. Other options include glass scales, A-axis torque drive, a grinding wheel measuring probe and a manual support steady rest.

About UNITED GRINDING North America, Inc.

With nearly 200 employees across the U.S., Canada and Mexico and a new 110,000-sq.-ft. headquarters in Miamisburg, Ohio, UNITED GRINDING North America, Inc., strives to increase its customers’ competitiveness through grinding and ultra-precision finishing solutions for the manufacturing industry, backed by single-source customer care. The company’s surface and profile, cylindrical and tool grinding technology groups cultivate a partnership-based relationship throughout the region, selling, automating, rebuilding and supporting precision machines for grinding, eroding, laser ablation, combination machining and measuring under the MÄGERLE, BLOHM, JUNG, STUDER, SCHAUDT, MIKROSA, WALTER and EWAG brands. A subsidiary of the UNITED GRINDING GROUP, the company holds ISO 9001 certification to assure quality in development, production, shipping and support operations. UNITED GRINDING North America, Inc., also holds International Traffic in Arms Regulations (ITAR) Registration.

About UNITED GRINDING Group

With a turnover of around 700 million euros, the UNITED GRINDING Group is one of the world’s leading manufacturers of precision machines for grinding, eroding, lasering, measuring and combination machining. With its eight company brands MÄGERLE, BLOHM, JUNG, STUDER, SCHAUDT, MIKROSA, WALTER and EWAG, UNITED GRINDING offers a broad application knowledge, an extensive product portfolio and a complete array of services on the international market. The Group employs a workforce of around 2500 employees and more than 20 production, service and sales locations and agencies throughout the world.