Toyota Material Handling Europe has placed an order for the newest technology offered by Modig Machine Tool – the RigiMill. Toyota Material Handling carries out development, manufacturing, and sales of material handling equipment.

Patrick Petterzon, Project Leader within the production organization at Toyota Material Handling said “We were impressed with the material handling capabilities of RigiMill and the technical competence of Modig. RigiMill will dramatically reduce stand still when changing tools and this reduced cycle time will help us optimize productivity and reduce tooling costs.” Cycle time is expected to be reduced at least 30%.

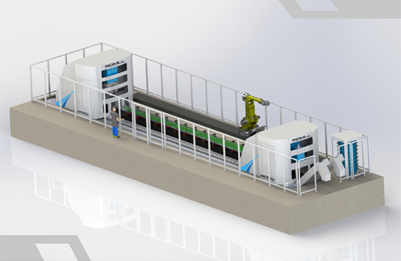

RigiMill is the market’s first ’two in one’ machine for heavy machining in titanium. “For the first time ever it is possible to operate one machine for optimal roughing and optimal finishing” said Modig President David Modig. As with all Modig Machine Tool systems, the unit is customized for each specific customer’s need. In the case of Toyota Material Handling, this is for cutting steel. The system is built for the characteristics of each metal to be machined – stiff for heavy cutting, and fast with a wide spindle for aluminum.

RigiMill is the market’s first ’two in one’ machine for heavy machining in titanium. “For the first time ever it is possible to operate one machine for optimal roughing and optimal finishing” said Modig President David Modig. As with all Modig Machine Tool systems, the unit is customized for each specific customer’s need. In the case of Toyota Material Handling, this is for cutting steel. The system is built for the characteristics of each metal to be machined – stiff for heavy cutting, and fast with a wide spindle for aluminum.

David Waldron, President of Modig’s US operations, commented “The RigiMill is an exciting and disruptive technology that generates a tremendous return on investment for our customers, especially when coupled with an integrated pallet system for loading raw materials and unloading finished product. We are happy to run time studies for our customers to demonstrate the strong value-add delivered by the RigiMill.”

Founded in 1948, Modig has continuously enhanced its reputation through its HHV ExtrusionMill, HHV BarMill and six-axis FlexiMill prior to the game changing RigiMill, another revolutionary product from Modig.

For more information please visit:

www.modig.se

Or contact:

david.modig@modig.se | David Modig

or

david.waldron@modig.se | David Waldron