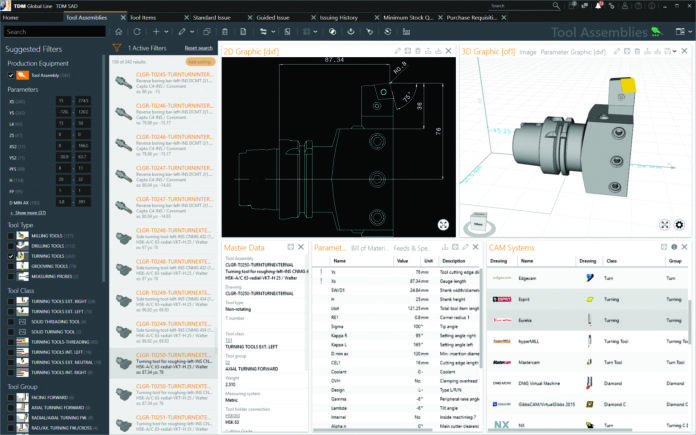

TDM Systems, the digitalization specialist and a leading provider of tool data management systems for industry has announced the latest version of its TDM and TDM Global Line. The releases offers numerous enhanced developments as well as new modules that help users reduce their tooling costs and increase their efficiency.

“For the user, the key to being more cost-effective, quicker and more agile in manufacturing is digitalization. Machining companies can now take a further step towards networking and data usage thanks to the latest generation of the TDM and TDM Global Line tool management software,” said Dietmar Bohn, Managing Director of TDM Systems.

With the new TDM Global Line 2020 release, users achieve greater transparency regarding their tooling costs and key figures. This is possible because each user can now individually configure their TDM Global Line dashboard. The relevant reports can then either be displayed in the dashboard, printed out or simply transferred to Excel.

In addition to numerous improvements and further developments in the TDM Shopfloor Manager and the Tool Crib apps, the latest release also provides new modules in TDM Global Line such as TDM NC-Program Manager Global Line a powerful tool guarantees a continuous production process, while the existing application expertise is retained by the company.

The TDM Purchase Request Module Global Line can be used to easily manage tool requirements and forward them to an ERP system. This helps the company to provide all the required tools at the right time and in the right quantities.

The TDM Barcode Module Global Line that expands the Global Line Tool Crib and allows companies to easily control processes by using barcodes. The TDM 3D Solid Editor Global Line that can be used to easily modify and adapt 3D models helping achieve significant time-savings when creating 3D models.

In addition to TDM Global Line, the tool data specialist also has further developed its core solution, TDM.

With the new release, the TDM 2020 Feeds & Speeds Manager is featured. In conjunction with the Comara Box, the actual applied cutting data is recorded, compressed and evaluated directly from the machine. By comparing the planned cutting values that are defined in the NC program with the actual applied cutting values in the machine it is possible to specify reliable cutting values as early as the planning phase. Another advantage of using the TDM Feeds & Speeds Manager is that the expertise from production is saved centrally so that even if employees leave the company, the knowledge is retained.

With the latest release, many of the improvements are also the result of an intensive exchange with the customers of TDM applications. In doing so, some applications for data and graphics maintenance have been optimized based on practical experience. Also, with the 2020 release, the completeness check of CAM-specific tool data has also become more transparent, as is the automated calculation of collision data. This is something that is particularly advantageous for CATIA and NX users.

About TDM Systems

For more than 25 years, TDM Systems has been the leading provider of Tool Data Management in the machining industry. With the Tool Lifecycle Management strategy, TDM Systems is focusing on process optimization through optimal tool planning and provisioning. Creating and editing tool data and graphics, integrating tool know-how and 3D graphics into the CAM planning and organizing the complete tool cycle on the shop floor level are the three core competencies of TDM Systems. As a member of the Sandvik Group, TDM Systems draws on the expertise of various tool manufacturers in developing its software products.