Leaving Your Mark on the World Not on Your Wall (or your technicians)

Material Testing can have risks. When a technician is taking a material to its failure limit, forces are large, and things can go wrong. I think everyone in this industry has had something happen that wasn’t supposed to.

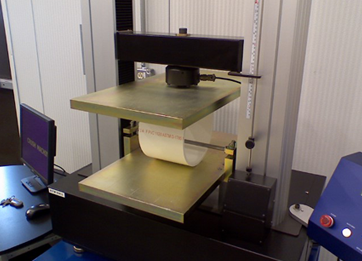

Many years ago, when we were first asked to build compression testers for pipe to ASTM D2412, being fairly paranoid, one of my concerns was the pipe sample shooting out from the compression platens and hurting someone. So we designed a simple, strong, effective keeper mechanism that will prevent this from happening.

Many years ago, when we were first asked to build compression testers for pipe to ASTM D2412, being fairly paranoid, one of my concerns was the pipe sample shooting out from the compression platens and hurting someone. So we designed a simple, strong, effective keeper mechanism that will prevent this from happening.

Sure enough, over the years visiting labs, we recently found some marks in the wall behind a compression tester, (not ours), where the sample let loose, and left a 1/4 inch deep pipe sample indentation in the drywall. If it would have sprung the other way, it would have really stung.

This is a small example of how TSI puts the experience of over 30 years building test equipment to work protecting your technicians, your company, and your building.

With some of their engineers having over 30 years of industry experience, the team at Testing Solutions Inc. is well known for their quality and expertise with testing requirements for the plastics industry. In addition to Compression Testing per ASTM standard D2412, other test systems available from Testing Solutions Inc. include:, Quick Burst Testing per ASTM D1599, Hydrostatic Testing per ASTM D1598, Impact Testing per ASTM D2444, Ring Tensile for ASTM D2290, and many others.

TSI will also build your custom testing system if a standard unit does not exist.

For more information, please visit:

www.pipetesters.com

Or contact:

website@tsiq.com