Orbital wrapping machine manufacturer TAB Industries, LLC, Reading, Pa. (www.tabwrapper.com), has increased the amount of component parts that are “Made in USA” in its TAB Wrapper Tornado line of pallet wrappers to 90 percent. Now manufacturing more than 40 different parts per orbital wrapper in its Reading, PA facility, the company increased the use of in-house and locally sourced components as a key part of its business strategy to help insulate production from global supply chain disruptions and permit faster lead times. Recent investments in fabricating, welding, automated laser cutting, and CNC machining equipment have eliminated reliance on outside suppliers and accelerated lead times by approximately two weeks. Current lead times for the standard model wrapping system are at eight weeks.

First manufactured in 2011 using only [40?] percent of component parts that are “Made in USA”, the TAB Wrapper Tornado orbital wrappers today feature heavy gauge steel wrapping rings, laser cut machine guarding, a variety of latches, clips, and plates, and advanced electronics, all designed, manufactured, assembled, wired, and programmed in-house and delivered ready to plug in and operate. The company’s streamlined production capabilities also promote fast delivery of replacement parts.

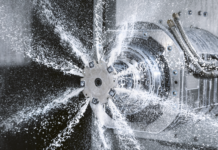

The TAB Wrapper Tornado line of orbital wrapping machines automatically apply stretch wrap 360 degrees around and under the pallet and load to create a sturdy, secure, unitized load in seconds without banding, boxing or strapping. Testing is offered using customer-supplied pallet loads to verify performance.