Hosting companies – Atlantic, Fraunhofer IZFP, Gontermann-Peipers, Herkules, IMS Messsysteme, Lechler, Lismar, Quaker Chemical, REBS, Schaeffler, and Steinhoff – spearheaded the event with numerous lectures detailing their newest developments for critical applications in metal production. Smart industrial engineering ecosystems, inspection technology, coatings and energy-efficient heat treatments were just a few of the topics covered by experts over the course of the two-day conference.

Representatives from Atlantic Grinding Wheels and Honing Stones, Alexander Arnold and Christian Mohr, presented their latest advancements in hot and cold steel and aluminum rolling to an audience of roll mill operators, surface inspectors, process engineers from more than 20 of the region’s biggest players in metal production.

“Cold and Hot Rolling Day was a perfect opportunity to present Atlantic’s cutting-edge Krypton wheel grinding technology that has proven capacity to increase the lifetime of a standard wheel 2.5 fold, while preventing feed lines and chatter marks in the surface of the processed material – we were thrilled to have this platform to share our innovative products with both existing and potential partners,” explained Arnold, Product Engineer at Atlantic.

Surface inspection professionals were particularly drawn to Fraunhofer-Institut IZFP’s lecture on non-destructive testing technologies for the industry, during which Dr. Ralf Tschuncky, Senior Scientist Electromagnetics in the department of Materials Characterization, and Dr. Marc Bläsing, Research Manager, described the benefits of eddy current testing for fault detection in Aluminum strips.

Gontermann-Peipers, a seventh generation family-owned foundry and machining company dating back to 1825, enthralled roll shop owners and operators in Memphis with Senior R&D Manager, Peter Heisterkamp’s introduction of the company’s state-of-the-art backup rolls, like its compound cast and forged rolls, as well as its newly developed compound, iron-core, spun-cast backup roll.

Ralf Klews, Senior Sales Manager at Herkules, unveiled his company’s roll shop optimizing control technology, which is web-based, and features Smart Grind, Safe Touch and Transparent Process View as well as comprehensive integrated advanced quality control applications. This software employed in combination with Herkules’s series of modular hardware systems offers users a multitude of benefits, including up to 50% shorter grinding times, extended roll lifetimes, increased surface quality, and overall high productivity of mills.

IMS, a leading German company in innovative inspection technology, highlighted its two-year partnership with Big River Steel, a big name in the U.S. steel producer landscape, through which the two companies were able to join forces to lay the groundwork for 3D slab inspection technology. “Our 3D inspection solutions allow product managers to precisely identify relevant defects on slabs with more accuracy than the traditional 2D scans,” elaborates Thomas Köpsel, Sales and Product Manager at IMS.

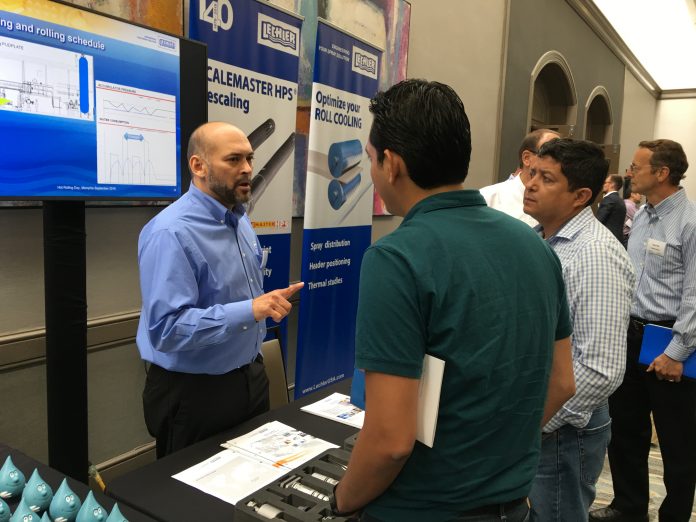

A subsequent presentation addressed one of the biggest energy-consuming processes in hot strip mills – descaling. Director of Metallurgy at Lechler, Jürgen Frick, described how a simple exchange of descaling nozzles to the Scalemaster HP Superior would save operators enough resources to pay for the new hardware within one and a half months. Lechler’s patented nozzle’s energy-efficiency is attributed to its unique coreless stabilizer and improved tip design that concentrates kinetic energy of the spray onto a smaller area, which increases the impact of the nozzle so much so that another pump can be switched off entirely – resulting in notable savings in maintenance costs over time.

A subsequent presentation addressed one of the biggest energy-consuming processes in hot strip mills – descaling. Director of Metallurgy at Lechler, Jürgen Frick, described how a simple exchange of descaling nozzles to the Scalemaster HP Superior would save operators enough resources to pay for the new hardware within one and a half months. Lechler’s patented nozzle’s energy-efficiency is attributed to its unique coreless stabilizer and improved tip design that concentrates kinetic energy of the spray onto a smaller area, which increases the impact of the nozzle so much so that another pump can be switched off entirely – resulting in notable savings in maintenance costs over time.

Lismar, a Dutch company specialized in advanced manufacturing technologies, emphasized the importance of regular roll inspections to prevent in-service related wear or accidents. Ruud van Kollenburg and Sander Mul, Managing Director and Manager Development at Lismar respectively, introduced their solutions based on LRI and eddy current technology, and concluded that “LRI is the new platform for future inspection methods, and the only system that can be updated to the latest improved development for ET and UT – LRI ET is the fastest inspection system with the highest sensitivity and reliability with the proven capacity to detect cracks of less than 2 mm.” Van Kollenburg concluded that early detection of wear-and-tear was the key to minimizing down time and maximizing mill productivity.

Quaker Chemical and Rebs tackled the importance of hot and cold rolling lubricants as well as the benefits of air-oil lubrication in avoiding bearing failures and excessive lubrication costs.

Delving deeper into the topic of bearings, Michael J. White, Director of the Global Business Unit of Raw Materials at Schaeffler, held a presentation, entitled: “Integral Bearing and Service Solutions for Hot Rolling Mills,” during which the speaker explained the benefits of the company’s Mancrodur high-performance work roll bearings for hot strip mills as well as its state-of-the-art condition monitoring systems and coatings.

To round off the comprehensive speaker program of Cold and Hot Rolling Day 2019, guests of the event were invited to learn more about Steinhoff’s latest developments of roll grades for cold rolling processes from Dr. Hartmut Bruns, PhD in Materials Science and Sales Engineer at Steinhoff.

About Cold and Hot Day

Cold and Hot Rolling Day is an annual event that takes place across the globe, including Germany, Russia, China, Turkey, India, and now the USA. It is a unique opportunity for stakeholders in the field to gather, network, exchange industry know-how and best practices.