OMAX Corporation to Demonstrate Intelligent, Easy-to-Use Software for Abrasive Waterjet at JIMTOF 2016

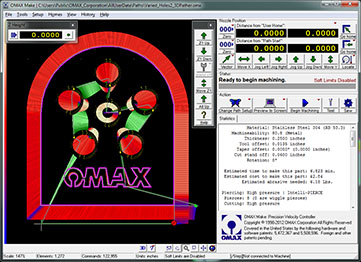

OMAX’s Intelli-MAX software has revolutionized abrasive waterjet machining, providing higher precision, faster cutting speeds and detailed predictive data all within an easy-to-use interface.

At JIMTOF 2016 held at Tokyo Big Sight November 17-22, OMAX® Corporation will show how its Intelli-MAX® software has made the company a global leader in the abrasive waterjet industry. At the core of Intelli-MAX software is an advanced cutting model that precisely predicts cutting speeds, taper, jet lag and other abrasive jet behaviors across a wide variety of materials and machine configurations. In Stand E7005, OMAX will demonstrate how easily an operator can access and apply this technology for fast, high-precision waterjet machining of almost any material.

Years of research and real-world data has enabled OMAX to develop a sophisticated software cutting model that takes into account characteristics specific to abrasive waterjets. The cutting tool used in abrasive waterjets is a stream of water, air and abrasive. The characteristics of this soft or “floppy” cutting tool are very different from those of rigid cutting tools found in traditional machines. The OMAX software cutting model incorporates algorithms for the unique dynamics of the waterjet cutting stream and the mechanical properties of various materials. This cutting model enables the Intelli-MAX software to optimize each job for speed and precision. The cutting model also enables Intelli-MAX to display accurate predictive data such as cost, abrasive used and production time for each job before cutting begins.

Years of research and real-world data has enabled OMAX to develop a sophisticated software cutting model that takes into account characteristics specific to abrasive waterjets. The cutting tool used in abrasive waterjets is a stream of water, air and abrasive. The characteristics of this soft or “floppy” cutting tool are very different from those of rigid cutting tools found in traditional machines. The OMAX software cutting model incorporates algorithms for the unique dynamics of the waterjet cutting stream and the mechanical properties of various materials. This cutting model enables the Intelli-MAX software to optimize each job for speed and precision. The cutting model also enables Intelli-MAX to display accurate predictive data such as cost, abrasive used and production time for each job before cutting begins.

At JIMTOF, visitors to the OMAX stand can see this software cutting model in action on a 2652 JetMachining Center. Although the software behind the scenes is complex, the intuitive user interface of the Intelli-MAX Software Suite lets the machine operator Waterjets at JIMTOF 2016 harness and apply the technology in a few simple steps. This software can import files from all major CAD/CAM programs and drawing programs. Intelli-MAX automates most programming and tool set-up work, eliminating the need for extensive operator training or special skills. The software can calculate and set the optimal lead-in lengths, pump pressure and cutting head motion speed for each individual tool path, freeing the operator from manual calculations and adjustments. The operator simply imports or creates a tool path, enters the material type and thickness and selects the desired edge quality. The software does the rest.

The 2652 machine at JIMTOF will be fitted with a Tilt-A-Jet® cutting head accessory to demonstrate its taper-free machining capability. By simply turning on optimizations in Intelli-MAX, the angle of the nozzle will adjust during cutting to remove taper, producing parts with square, taper-free edges, including interlocking pieces and dovetail fittings.

Visitors to the OMAX booth will experience the machine’s performance using an optional 40 hp (30 kw) pump. The direct drive pump design delivers greater power to the nozzle than intensifier pumps with the same size electric motor and power consumption. This translates to higher machining speeds and lower production costs.

OMAX staff will be on hand in Stand E7005 to demonstrate the software and hardware, answer questions, and discuss how abrasive waterjet technology can increase your company’s productivity. OMAX Corporation has 30 international distribution partners serving the machining industry around the globe. These distributors provide manufacturers with increased access to the company’s waterjet technology as well as applications support, training and expert service technicians. To learn more about OMAX’s distribution partners, please visit www.omax.com/sales/international.

About OMAX Corporation

Based in Kent, Washington, OMAX Corporation is the global leader in advanced abrasive waterjet systems that cut virtually any material and thickness with unmatched speed and accuracy. Owner of the OMAX and MAXIEM brands, the company provides a comprehensive selection of JetMachining Centers that feature intuitive software controls and incorporate the most efficient pump technology available. In developing its machines, the company designs, manufactures, assembles and tests components as a complete system to ensure optimum performance. The company also has the most comprehensive service and support network in the waterjet industry to keep its customers ahead of the manufacturing curve.

For more information, visit www.omax.com.