Jorgensen Conveyor and Filtration Solutions, now a member of the Innovance family of companies, will feature key products from its comprehensive lineup of conveyor, material handling, coolant and filtration solutions at IMTS 2024, Sept. 9 -14, in Chicago, Illinois. Visitors to booth 338009 in the South Hall of McCormick Place will experience a cutting-edge PermaClean system equipped with the new EcoFilter®80 self-cleaning conveyor and a Will-Fill automated coolant system; MunchMan® Dual-Belt Conveyor; FlexForce high-pressure system with a new chiller option; next generation Magnetic Conveyor for ferrous materials; ER20T Eco Briquette Press; and the Flex G line that’s part of the company’s FlexFiltration systems.

Jorgensen’s new EcoFilter® 80 self-cleaning conveyor enables efficient filtration of fine chips to 80-microns nominal. It is the first economical non-drum style conveyor offering filtration below 100-micron. EcoFilter® conveyors use non-disposable filter boxes that dramatically reduce chips and particulate from migrating to a machine tool coolant tank. Users experience reduced downtime for tank cleaning and maintenance as well as improved pump, tooling and coolant life.

The new EcoFilter80 will be part of the revolutionary PermaClean system. The PermaClean system adds options for secondary tank filtration and eliminates sludge build up by adding agitation to the coolant collection tank. PermaClean can be incorporated into Jorgensen’s multi-step filtration system and is adaptable as an option to nearly any filtration system on the market.

The new EcoFilter80 will be part of the revolutionary PermaClean system. The PermaClean system adds options for secondary tank filtration and eliminates sludge build up by adding agitation to the coolant collection tank. PermaClean can be incorporated into Jorgensen’s multi-step filtration system and is adaptable as an option to nearly any filtration system on the market.

The PermaClean system will also be equipped with a Will-Fill total coolant health system that offers trouble-free monitoring of metalworking emulsion. The system combines automatic measuring, filling and conditioning. It alerts operators via a flashing color LED, buzzer, or e-mail when attention is required.

For applications that produce long, stringy or nested balls of chips, Jorgensen’s MunchMan® dual-belt conveyor is a heavy-duty unit designed to grab chips as they move into the conveyor’s incline section, greatly reducing or eliminating conveyor jamming problems. MunchMan® conveyors are custom fabricated to meet customer requirements and are compatible with other Jorgensen coolant management options.

For applications that produce long, stringy or nested balls of chips, Jorgensen’s MunchMan® dual-belt conveyor is a heavy-duty unit designed to grab chips as they move into the conveyor’s incline section, greatly reducing or eliminating conveyor jamming problems. MunchMan® conveyors are custom fabricated to meet customer requirements and are compatible with other Jorgensen coolant management options.

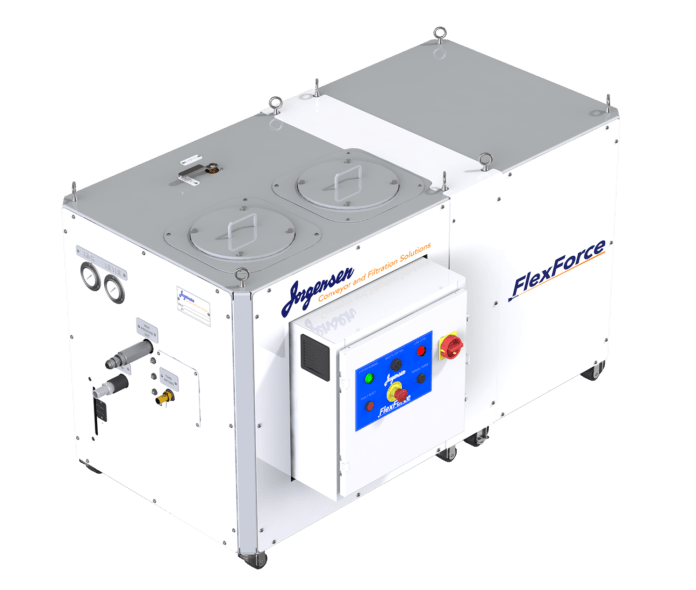

Booth visitors will also see a new FlexForce high-pressure coolant system for through-spindle coolant system (TSC) applications. Jorgensen will display the 1,000-psi configuration featuring a new chiller option. FlexForce gets coolant directly to the cutting zone, improving lubrication and heat dissipation. The outcome is improved cutting speeds and feeds, chip control and part surface finishes.

For moving ferrous materials such as small chips, fines, small parts and stamping slugs, the company will display its next generation Magnetic conveyor. The conveyor has been redesigned and built using updated engineering and manufacturing standards for improved performance. Effective in heavy oil and grease applications, Jorgensen’s Magnetic conveyors are custom fabricated, safe and maintenance friendly.

For moving ferrous materials such as small chips, fines, small parts and stamping slugs, the company will display its next generation Magnetic conveyor. The conveyor has been redesigned and built using updated engineering and manufacturing standards for improved performance. Effective in heavy oil and grease applications, Jorgensen’s Magnetic conveyors are custom fabricated, safe and maintenance friendly.

Jorgensen’s metal compacting solutions are designed for sustainable manufacturing and recycling. Visitors to Jorgensen’s booth will see the ER20T Briquette Press that uses hydraulic pressure to condense chips while pushing out residual cutting fluid. Jorgensen’s chip processing solutions include turn-key systems for chip shredding, wringing and compacting and are highly effective for steel, aluminum, titanium, brass, cast iron and grinding sludges.

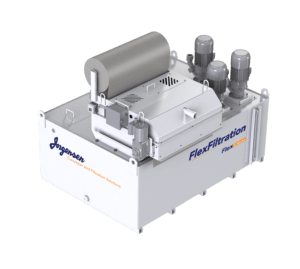

Jorgensen will showcase its modular FlexFiltration system with the Flex G Series in a new 25-gpm configuration. Flex G Series systems use gravity media filtration and come standard with low media roll detection, no media alarm sensor and automatic roll advance. FlexFiltration systems feature either cyclonic bag or gravity media filtration options that can be configured to efficiently remove fine chips and grinding sludge down to 10 microns or less. They are especially well suited for challenging applications involving materials ranging from cast iron, steel and aluminum to composites and plastics.

Jorgensen will showcase its modular FlexFiltration system with the Flex G Series in a new 25-gpm configuration. Flex G Series systems use gravity media filtration and come standard with low media roll detection, no media alarm sensor and automatic roll advance. FlexFiltration systems feature either cyclonic bag or gravity media filtration options that can be configured to efficiently remove fine chips and grinding sludge down to 10 microns or less. They are especially well suited for challenging applications involving materials ranging from cast iron, steel and aluminum to composites and plastics.

Innovance sister companies ALMCO and Mass Finishing, Inc. (MFI) will be joining Jorgensen this year at IMTS. In addition to manufacturing a robust line of standard industrial parts washers, polishers and deburring machines, the companies also offer custom solutions to meet specific customer requirements.

About Jorgensen Conveyor & Filtration Solutions

With over 70 years of experience in designing and manufacturing advanced conveyor, coolant filtration and chip processing solutions for machine tool, metalworking, and material handling, Jorgensen Conveyor & Filtration Solutions offers a wide range of standard and customized systems to companies across North America and globally. All products are engineered to provide high quality, cost effective, application-based product solutions for even the most demanding environments.

For problem free production and material handling without bottlenecks caused by maintenance intensive systems, poor chip management or coolant filtration, the company manufactures reliable, innovative conveyor and filtration solutions, including MunchMan®, EcoFilter®, Filterveyor®, FlexFiltration, FlexForce, PermaClean, and Will-Fill.

Jorgensen is a 100% employee owned Innovance company that sets the industry standard for quality, reliability, and value for all your material handling needs.