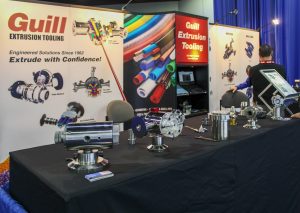

Interwire, the largest and longest-running wire and cable show, took place between May 13 and May 16, at the World Congress Center in Atlanta, Georgia. Guill Tooling & Engineering had quite a turnout at their booth. Company personnel were able share their knowledge and interact with many potential customers.

At booth #1511, Guill was showcasing some of its latest technology. Featured were the in-line 5 layer extrusion crosshead of Series 800, single-point concentricity extrusion crosshead and Bullet II extrusion head.

Guill’s 800 Series is designed to produce the highest quality, highest material-efficient OD

tubing for automotive, medical, appliance and industrial applications. This series produces smooth extrusion and layer definition of fluropolymer and other materials for all multi-layer, multi-lumen medical tubing, as well as fuel line constructions, multi-layer PEX pipe and drip irrigation applications.

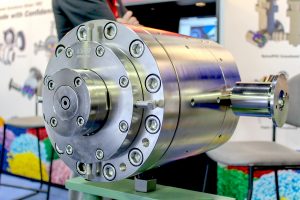

The single-point concentricity crosshead uses micro-fine adjustment screws for precise concentricity. This adjustment is a unique feature of the company for the extrusion of thin-walled jacketing and precision ID/OD tubing. It not only accepts both vaccum and micro-air accessories, but is also ideal for pressure and sleeving applications.

Introduced in 2015, the Bullet was a new extrusion head with fixed center design, multi-

port spiral flow design and gum space adjustment. There was no need for fastening hardware, so cleaning and restart were easier. The Bullet II allows quick tooling changes, as the tips remove from the back and the die removes from the front. Guill’s CAM LOCK® deflector removes and installs the deflector and tip with just half a turn. Hassle free air and vacuum connections are available, in addition to reduced downtime and lowered operating costs. High-volume and low-volume applications are suitable for this crosshead.