Global industrial automation leader FANUC America takes the machining world to the next level with the new FANUC Series 500i-A CNC. This new control series advances machine performance with 5-axis integrated technology and supports both machine tool builders and CNC users with their evolving needs including easier operations, more security and optimized efficiency. FANUC America will be introducing the new 500i-A CNC at the 2024 International Manufacturing Technology Show in Chicago, IL., Sept. 9-14 in booth S-338919.

With its dual engine architecture, the new control has 2.7 times higher CPU processing power than previous models and comes with updated modern hardware and graphically enhanced software. This higher performance, including improvements in both block processing time and macro program processing, is designed to help machine shops drive down cycle times with faster speeds and improved productivity.

“With the market demands and challenges, we know there is a real need to make parts quicker, better and easier,” says Jon Heddleson, General Manager of the Factory Automation Division for FANUC America. “The 500i-A CNC will help the industry by providing optimized 5-axis integrated technology, which more shops are moving towards. Plus, the new controls are designed to simplify operation and maintenance.”

The FANUC Series 500i-A CNC has all the benefits of FANUC’s other control platforms, such as high precision, accuracy and rock-solid reliability, but with additional benefits attained from the latest CNC features as well as the integration of FANUC’s new generation servo system Alpha i-D Series.

“FANUC’s new generation servo system delivers high speed and high precision while reducing energy loss,” says John Horn, National Sales Manager for FANUC America’s Factory Automation Division. “The Alpha i-D servo motors are designed with increased speed-torque characteristics, offer superior protection through the IP67 rating as standard and can be ordered with battery-less encoders. The drive systems have a smaller footprint to save cabinet space, helping to make the entire system more efficient.”

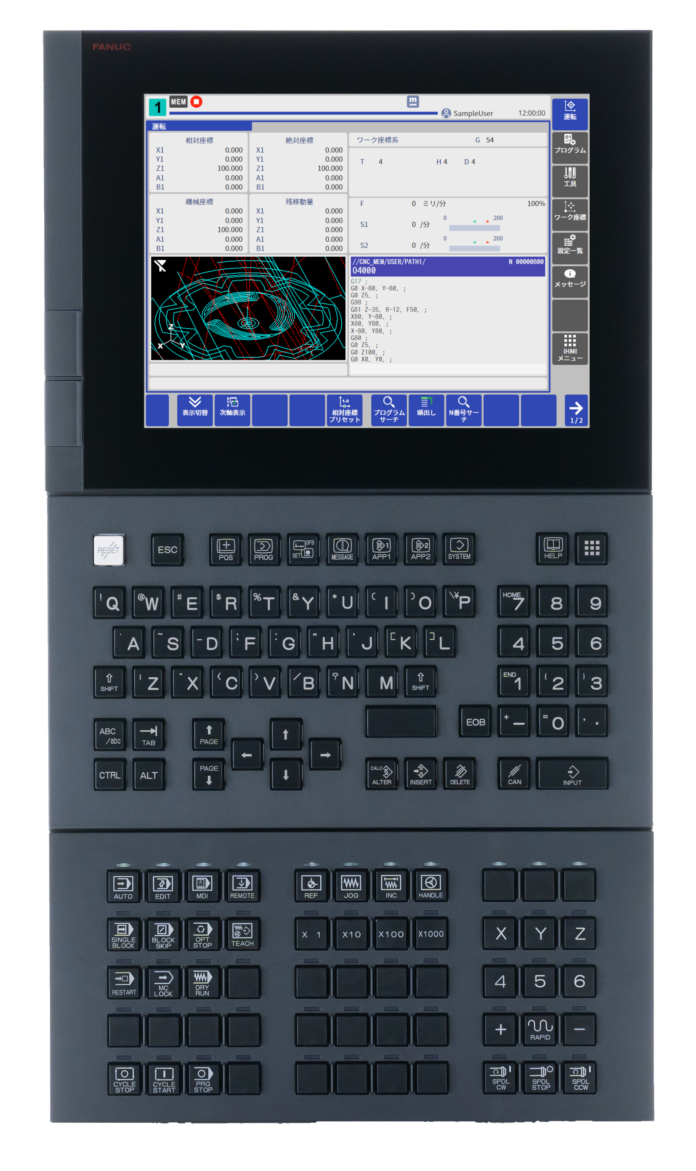

Another key upgrade to the 500i-A CNC is the new control’s modern iHMI2 interface, which has a simplified display with 1-1 task-to-screen eliminating the need to switch between screens. Plus, maintenance has never been easier with the control’s battery-less system.

FANUC CNC systems, including the new 500i-A CNC, continue to advance IoT efforts via centralized data collection and management software offerings while guarding against cybersecurity issues with features like FOCAS3, user authentication and data access protection.

FANUC also continues to support our machine tool builders with a wide array of development tools to help them go to market with the best equipment possible. These tools are designed to optimize machine tools, including improved user experience, faster cycle times and better performance. The FANUC Series 500i-A CNC offers digital twin technology to assist in complex machine design, plus, provides the ability of builders to fully customize user interfaces.

About FANUC America Corporation

FANUC America Corporation, a subsidiary of FANUC CORPORATION in Japan, provides industry-leading CNCs, robotics and ROBOMACHINEs. FANUC’s innovative technologies and proven expertise help manufacturers in the Americas maximize productivity, reliability and profitability.