Featuring Pipe Beveling Tools & Saws

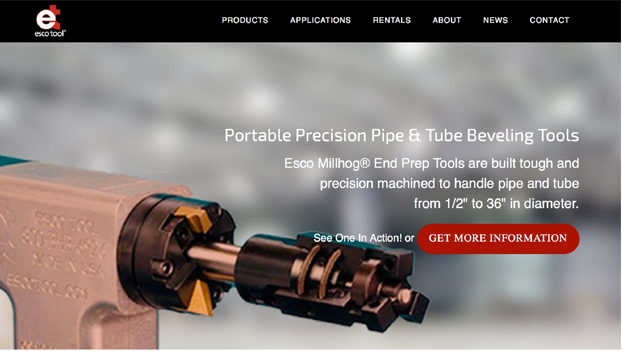

An updated website featuring a wide range of portable precision pipe and tube beveling tools for onsite boiler tube and pipeline and in shop pipe fabrication is being introduced by ESCO Tool of Holliston, Massachusetts.

The ESCO Portable Precision Pipe & Tube Beveling Tools Website features Millhog® end prep tools that can bevel, face, and bore without cutting oils; air powered saw kits for cutting pipe without leaving a heat affected zone; and rolling motors and tube expanders. Included are product specifi-cations, motor and drive options, key features, applications, and videos.

Easy to identify the Millhog® end prep tools suited for pipe and tube from 1/2” I.D. to 36” O.D. and saws for pipe from 6” to 60”, with click-through for specifications, the ESCO Portable Precision Pipe & Tube Beveling Tools Website describes their rental tool program, company background, and has an extensive archive of new product and product application news releases.

About Esco Tool:

The ESCO Tool Company was founded in 1954 and developed the first portable end prep tool for the Triton Nuclear Submarine program. Those early tools clamped to the tube O.D. and machined precision end preps on nozzles that were attached to a vessel. Back then, there was no other way to do the job. After this early success, other uses where found for these innovative tools and they became the best way to end prep high temperature and pressure boiler tubes.It became apparent, however, that O.D. clamping limited the usefulness of those early generation tools for boiler work. Always solutions-oriented, ESCO developed the first narrow body I.D. clamping tool in the 1970s to satisfy the needs of the boiler industry. The tool was well received in the boiler fabrication, maintenance, and metalworking industries and ESCO has been innovating consistently since that time. Working closely with end-users on the toughest tube and pipe cutting and welding end prep challenges has allowed us to invent and manufacture high quality tools that work efficiently, get the job done fast, and require no special operator training. ESCO Tool has a long heritage of innovation.

Today, our MILLHOG® Tools are boilermaker tough and field proven! We design and build robust gear drives and housings, select the best components available in the world, incorporate self-centering draw rod assemblies that rigidly mount to the tube or pipe I.D., and feature the EscoLockTM wedge-style blade lock system with TiN (titanium nitride) coated cutter blades that direct heat away from the tube or pipe surface. Providing torque-free operation, these tools pull a continuous thick chip without cutting fluids.

MILLHOG® Tools are available for sale or rent. A major reason why our tools are so well engineered today is because we have been able to tear-down and evaluate our rental tools for many years. This has allowed us to engineer, upgrade, and develop new tools based upon the real-world requirements of boilermakers. There’s no guesswork here. Today we manufacture over 20 models and versions of field-proven MILLHOG® Tools and provide them to end-users directly and through a worldwide network of distributors. If you’re a longstanding customer of Esco Tools, we appreciate your business. If you’re a first time visitor to our web site, we welcome the opportunity to earn your business.

For more information, please visit:

www.escotool.com