- ExOne, the digital casting brand of Desktop Metal, produces binder jet 3D printers for producing sand castings

- BMW Landshut casts aluminum parts using a fleet of four ExOne 3D printers for serial production of cores using inorganic binders that generate no odors or emissions

- ExOne’s binder jetting technology supports delivering complex designs for casting aluminum powertrain components

Desktop Metal, Inc. (NYSE: DM), a global leader in Additive Manufacturing (AM) technologies for mass production, released a video showcasing how the BMW Group uses ExOne binder jet 3D printers for the serial production of casted powertrain components.

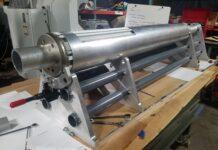

ExOne and the BMW Group have been working together for more than 20 years on project development. The automaker uses four ExOne Exerial binder jet 3D printing systems for serial production of water jacket cores used for metalcasting, with two more systems slated for delivery. When combined with a microwave, a desanding station, and a fully automated conveyor system, the complete Exerial system runs high-speed 24/7 production and delivers high-accuracy parts. Take a look Inside the pioneering AM journey of ExOne and BMW at TeamDM.com/BMW.

In binder jetting, an industrial printhead selectively deposits a binder into a bed of powder materials — such as sand, metal, or ceramic — creating a solid part one thin layer at a time. When used for sand casting, the sand part is removed and assembled into a mold package used for casting molten metal. Binder jet 3D printing technology is widely viewed as a desirable and sustainable production method, largely because of its high speed, low waste and cost, as well as material flexibility.

About Desktop Metal

Desktop Metal (NYSE:DM) is driving Additive Manufacturing 2.0, a new era of on-demand, digital mass production of industrial, medical, and consumer products. Our innovative 3D printers, materials, and software deliver the speed, cost, and part quality required for this transformation. We’re the original inventors and world leaders of the 3D printing methods we believe will empower this shift, binder jetting and digital light processing. Today, our systems print metal, polymer, sand and other ceramics, as well as foam and recycled wood. Manufacturers use our technology worldwide to save time and money, reduce waste, increase flexibility, and produce designs that solve the world’s toughest problems and enable once-impossible innovations.