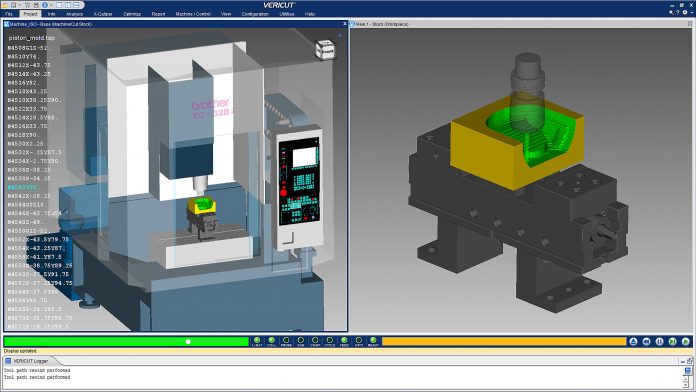

At the 2018 International Machine Tool Show (IMTS), September 10-15, 2018, CGTech’s VERICUT Product Manager Gene Granata will be giving a presentation on choosing part optimization strategies. Attendees can attend the presentation on Thursday, September 13 at 11:00am in room W192-C. Throughout the show, the new release of VERICUT, version 8.2, will be featured in CGTech’s booth 133346. VERICUT CNC machine simulation, verification and optimization software simulates all types of CNC machining, including drilling and trimming of composite parts, water jet, riveting, robots, mill/turn and parallel kinematic/hexapods. It operates independently, but can also be integrated with leading CAM systems.

VERICUT is at the heart of the CNC manufacturing process for many of the world’s leading engineering businesses in all industry sectors, including: aerospace and defense, oil and gas, power generation, motorsport, automotive and transport, medical device and implant, as well as general precision and heavy engineering.

Machine simulation with VERICUT detects collisions and near-misses between all machine tool components such as axis slides, heads, turrets, rotary tables, spindles, tool changers, fixtures, workpieces, cutting tools, and other user-defined objects. Users can also set up ‘near-miss zones’ around the components to check for close calls, and detect over-travel errors. Machine movements can even be simulated while stepping or playing backwards in VERlCUT‘s Review Mode.

Modernized User Interface

Head-Up Display (HUD) shows the NC program or status items on top of Views. HUD keeps tabs on the NC program and important machine functions, while still keeping simulation Views as large as possible for optimal viewing. HUD is customizable. Program Alerts highlight errors and warnings in NC programs. You can hover over the alert to see exactly what the error or warning is. When running multiple NC programs, Program Alerts highlights the programs with errors in red.

Force Turning & Calibration

Force is a physics-based NC program optimization module that analyzes and optimizes cutting conditions throughout CNC Program operations. Force is available on Turning/Lathe and Milling machines. Force Turning makes it easy to change and limit the chip thickness and feed rates while cutting in corners, diameters, and tight spaces. Force Calibration creates Force Material Files from dynamometer test data, and includes a Design of Experiment (DOE) planner, validates data, and shows statistics.

Improvements to the Additive Module

VERICUT 8.2 adds realism to additive simulation to improve verification of the additive build processes. These processes include, but are not limited to: the buildup of overlaps, acute corners, tight overlapping bead paths, and double-deposits (overlapping start/end points). An alert message will appear when the laser focal point is too far from the part’s surface, when there are excessive overhang conditions, and/or when there is too much build up at corners and overlaps. The excessive corner and overlap alert helps determine when it may be beneficial to make a milling cut.

Other Products

VERICUT Composite Applications are being used by leading manufacturers to program and simulate automated fiber placement and tape-laying machinery from machine tool builders such as: Electroimpact, MTorres, AFPT, Automated Dynamics, Fives, Accudyne, BA Composites and others.

The automated drilling and fastening machines used for the production of aero-structure components are also supported by VERICUT Drilling & Fastening (VDAF). It allows the user to visualize and simulate CNC drilling and fastening machines using the same NC program code that will be run on the machine. Simulation is independent of programming, and VDAF can simulate NC programs from any programming system for any CNC-automated drilling and fastening machine.

With the modular format of VERICUT the software provides flexibility, so companies purchase only the capabilities they need. It is easy to add modules as required as CGTech provides a license that gives immediate access. VERICUT runs on Windows platforms and is delivered as 64-bit application. Post-processed G&M codes or CAM center-line (CL) formats are both supported.

About CGTech

CGTech’s VERICUT® software is the standard for CNC simulation, verification, optimization, analysis, and additive manufacturing. CGTech also offers programming and simulation software for composites automated fiber-placement, tape-laying, and drilling/fastening CNC machines. VERICUT software is used by companies of different sizes in all industries. Established in 1988, and headquartered in Irvine, California; CGTech has offices worldwide.

USA – Corporate Headquarters

9000 Research Drive

Irvine, California 92618-4214

P: 949-753-1050

F: 949-753-1053