During the upcoming GIFA 2011 show in Dusseldorf, Germany, Magma will present its new software generation for casting process simulation, MAGMA5. At the 300 sq. m stand 12A16, the company will demonstrate how casting process simulation with MAGMA5 can be used for optimization at all stages of casting manufacturing to contribute to foundry profitability. MAGMA will show the newest version MAGMA5 5.2 with extended capabilities for all cast materials and processes, introduce its new software MAGMA C+M for the simulation of the core production processes and provide a view into the future of autonomous optimization of casting processes. Additionally, MAGMA is participating in the initiative “ecoMetals” from the Messe Düsseldorf, which supports companies who develop innovative products and processes leading to a more efficient use of energy. MAGMA will demonstrate, using practical examples, how the application of casting process simulation considerably increases a foundry’s energy and resource efficiency.

MAGMA5 – optimized simulation

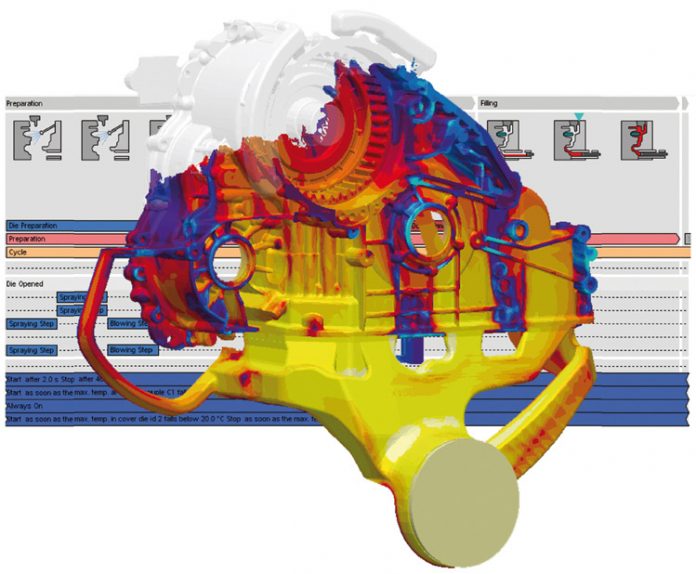

MAGMA5 5.2 introduces several new simulation capabilities: new process modes for permanent mold, low pressure sand and low pressure die casting, as well both hot-chamber and cold-chamber die casting, allow for detailed process-specific definitions. The software also supports process design by controlling process parameters during a simulation run. For gravity casters, process modules for DISAMATIC and investment casting are now available.

At GIFA, MAGMA will also present its newest developments for the quantitative prediction of as-cast and heat treated local microstructures and properties in aluminum, iron and steel castings. MAGMA5 simulates sand and reoxidation inclusions during mold filling and predicts defects related to molding materials. MAGMAnonferrous calculates the final microstructure and mechanical properties for aluminum alloys considering the metallurgy, inoculation, and hydrogen content of the melt. MAGMAiron predicts local microstructures for iron materials from graphite growth through to the distribution of phases making up the matrix. MAGMAsteel calculates macrosegregation in steel castings and the local microstructure resulting from heat treatment.

The stress module MAGMAstress for the first time offers casters the option to calculate thermally induced casting stresses in permanent molds for all manufacturing steps, including heat treatment and finishing, in order to predict casting crack problems and distortion. The simulated distortion results can be evaluated just as on a coordinate measuring machine and compared directly with real measurements. For the first time, the new module MAGMAdielife facilitates the evaluation of the effects of tooling design and thermal stresses on the durability of permanent molds.

MAGMA Core+Mold – transparency in core production

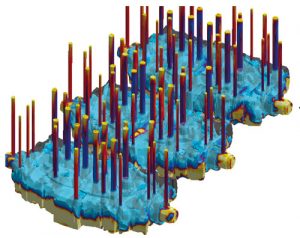

With MAGMA C+M, MAGMA introduces an integrated tool for the simulation of core production processes. MAGMA C+M simulates core shooting, blowing and hardening of organic and inorganic cores. Processes where binder hardening is driven by a catalyst gas as well as core production with tempered core boxes are supported. MAGMA C+M considers all aspects of core production starting from the core shooter, in order to calculate the flow of the air-sand mixture based on the real shot parameters. An integrated database provides the ability to specify the characteristics of the sand and the binder system as well as core box vents and blow tubes. The program simulates gassing, purging and the curing reaction of gas-hardened cores. The design and control of core box tempering for heat-cured cores (hotbox, croning, inorganic) is effectively supported by modeling of heating cartridges and oil channels. For inorganic cores, MAGMA C+M calculates the drying of the core in the heated core box as well as due to transport of water vapor by hot air during gassing. MAGMA C+M takes advantage of all the functionality of MAGMA5 and is available as an add-on module to MAGMA5 or as a stand-alone product.

Autonomous optimization is the future

Autonomous optimization is the future

With autonomous optimization, foundrymen can make use of simulation in order to pursue their objectives for quality and cost. Autonomous optimization makes proposals for the right casting layout or the optimum process parameters. The virtual test foundry in the computer enables variation of parameters and systematic examination of influencing variables leading up to the optimum configuration. Based on the fundamental physics embedded in MAGMA5, the program finds the best possible dimensions and positions of ingates, as well as the location of feeders and chills including their optimum size. Using industrial examples, MAGMA will present state-of-the-art capabilities and provide a view into the future of optimization.

MAGMA – very involved

At the accompanying WFO Technical Forum, MAGMA will give presentations on the topics of aluminum casting, core production, and optimization. At the NewCast exhibition, which takes place in parallel with GIFA, simulation specialists will discuss the prediction of residual stresses and distortion in cast iron components.

MAGMA also has a further exhibition stand (12A15) as part of the “Get-In-Form” project “Youth-Technology-Future” (“Jugend-Technik-Zukunft“). Here, the attractiveness of work as a professional or specialist in the metal casting industry will be illustrated to students and apprentices in an entertaining and interactive manner.

About software for casting process simulation

Casting process simulation software considers the complete casting process including mold filling, solidification and cooling, and also provides the quantitative prediction of mechanical properties, thermally induced casting stresses and the distortion of cast components. Simulation accurately describes a cast component’s quality upfront before production starts, thus the casting layout can be designed with respect to the required component properties. This results in a reduction in pre-production sampling, but also the precise layout of the complete casting system leads to energy, material and tooling savings for the foundry.

The range of application of MAGMA solutions comprises all cast alloys, from cast iron to aluminum sand casting, permanent mold and die casting up to large steel castings. The software supports the user in component design, the determination of melting practice and casting methodology through to mold making, heat treatment and finishing. This saves costs consequently along the entire casting manufacturing line.

During the last 10 years, the use of casting process simulation has become a valuable business asset for many foundries. MAGMA5 now expands the capabilities of casting process simulation and will further accelerate the acceptance of this technology.

About MAGMA

MAGMA offers comprehensive solutions to the metal casting industry, casting buyers and casting designers worldwide. The MAGMA product and service portfolio includes the powerful modular simulation software MAGMASOFT®, with the newest release MAGMA5, as well as engineering services for casting design and optimization.

Today, MAGMASOFT® is used throughout the metal casting industry, especially for the optimization of cast components in automotive and heavy industry applications.

MAGMA Giessereitechnologie GmbH was founded in 1988 and is headquartered in Aachen, Germany. A global presence and support are guaranteed by offices and subsidiaries in the USA, Singapore, Brazil, Korea, Turkey, India and China. Additionally, more than 30 qualified partners represent MAGMA around the world.