Several industries, such as power generation, chemicals, iron, and steel, have a carbon problem. The imperative to reduce carbon emissions has become more pressing than ever, as the regulatory bodies around the world set ambitious targets, timelines, and mandates, such as carbon taxes and emissions trading, to curb carbon emissions. Simultaneously, these hard-to-abate industries need to grapple with the steadily rising demand for energy that hinges on conventional carbon-emitting fossil fuels.

At the forefront of addressing these challenges are Carbon Capture, Utilization, and Storage (CCUS) technologies that catch and store carbon emissions before they are released into the air.

At the forefront of addressing these challenges are Carbon Capture, Utilization, and Storage (CCUS) technologies that catch and store carbon emissions before they are released into the air.

One of the critical challenges facing this important tool in the fight to reduce carbon emissions is upgrading the infrastructure and equipment across the value chain. Consider Carbon Capture (CC), a crucial component of CCUS, for example. It encompasses a collection of technologies at various technology readiness levels (TRLs), each presenting its own set of challenges. There are four major carbon capture technologies: Post-combustion, Pre-combustion, Oxyfuel combustion, and Direct Air Capture (DAC).

Four Promising Carbon Capture Technologies

To effectively address carbon challenges and find promising solutions, it’s essential to understand the differences in the four major CC technologies:

- Post-combustion is the most mature technology of the four, with the broadest versatility of applications, representing the largest market segment in carbon capture. It widely utilizes chemical (typically, amine-based) or physical (Selexol, Rectisol, Fluor™, etc.) solvents, with chemical solvents being highly dominant. Chemical solvents, together with CO2, are corrosive, which can impact seals and wear parts and lead to the failure of equipment, such as valves, pumps, and heat exchangers. Post-combustion technology is applied in a wide variety of industries, including power generation, petrochemicals, steel, and cement.

- Pre-combustion is the next leading technology, that could potentially be used in natural gas combined cycle plants, Integrated Gasification Combined Cycle (IGCC) plants and natural gas reforming process. Today’s commercially available pre-combustion CC technologies generally use adsorption processes which can be done by swinging pressure (PSA) or temperature (TSA). The pressure swing adsorption (PSA) process is more commercialized than TSA. The PSA process is also utilized to recover and purify hydrogen while carbon is being separated and that positions it as a favorable choice as demand for hydrogen grows. However, the process operates on high cycle rates (up to 200,000 per year), high process pressures, and bi-directional flows of feed gas. All these together can accelerate wear and cause reliability issues of equipment.

- Oxyfuel combustion utilizes nearly pure oxygen, by removing nitrogen from the air, for combustion. The main benefit of this technology is minimal nitrogen oxides production from the absence of nitrogen and the high yield of CO2 captured. Due to the higher concentration of oxygen, however, the process results in high temperatures (3000-4500°F+). Therefore, the equipment needs materials that can withstand high temperatures as well as corrosive environments from the high concentration of CO2. The biomass power industry, for example, utilizes Oxyfuel combustion, referred to as Bioenergy with Carbon Capture and Sequestration (BECCS).

- Direct Air Capture (DAC) is acknowledged as a negative emission technology because it captures CO2 directly from the atmosphere. While liquid solvents and solid sorbents are largely utilized in the DAC process, liquid solvents pose a corrosion threat to the process equipment. Although DAC is not yet ready for commercial deployment today, it has the potential for rapid growth, backed by government support in major markets, such as the US, Canada, the EU, and the UK. The latest developments are found in the use of CO2 captured from DAC technology in the cement and food & beverage industries.

Rising to Carbon Capture Challenges

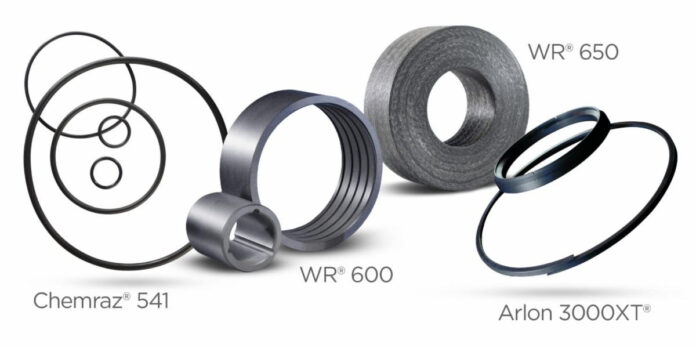

In response to these challenges, Greene Tweed’s portfolio of materials are reliable solutions that can outperform and outlast in the carbon capture market’s most demanding environments. Consider post-combustion or DAC processes that need high temperatures and aggressive solvents, for instance. Perfluoroelastomer (FFKM) O-rings such as our recently launched Chemraz® 541 perform very well in amine services. Components made from these advanced materials can contribute to the increase of reliability and lifetime of equipment such as mechanical seals, pumps, valves, absorbers, and regenerators. WR® 600 and WR 650® are PFA composite materials used in bearings and bushings for pumps that also exhibit excellent resistance to amines like DEA or MDEA at elevated temperatures. Some materials, such as Arlon 3000XT® cross-linked PEEK, offer an alternative when degradation of mechanical properties is a concern in applications such as column packings.

While navigating carbon capture applications, Greene Tweed’s Commercial and Engineering team stands ready to assist in selecting the optimal solutions for your needs. Contact Greene Tweed to learn how their material solutions can empower you in your journey toward sustainable and efficient carbon capture processes.