NASA Marshall Space Flight Center in collaboration with Jacobs Space Exploration Group has awarded 3DCERAM Sinto, Inc. a contract for a C1000 Flexmatic Ceramic Printer and to add 3DCERAM as a partner working with NASA. This printer will be used to make samples for small and large pieces of new and innovative materials that will be tested in space and other realitive extreme environments.

The first test parts will proceed immediately with the Materials International Space Station Experiment (MISSE) program. https://www1.grc.nasa.gov/space/iss-research/misse/

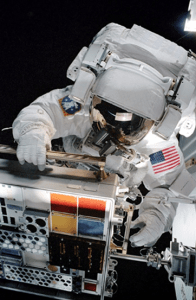

MISSE is a testing program designed to manufacture materials samples and secure them to a panel that will be mounted outside of the International Space Station to study the effects of outer space on 3D Printed products. 3DCERAM Sinto Inc will be making 20 sample parts to be launched to the space station for the MISSE program next year. The parts will be made as part of the evaluation process for ceramics that may one day be used on the outside of vehicles in space. The samples will remain there for six months in order to gain knowledge about the printed ceramic material’s ability to withstand the space environment. These tests will demonstrate the effects of in-space environmental exposures, such as zero gravity and radiation from the sun. Once these materials and manufacturing processes are characterized in space, flight worthy hot structures and heat shields could be printed on the 3DCERAM C1000 Flexmatic. The C1000 Flexmatic will allow NASA to print large and fully dense parts or many parts on the 320 mm x 320 mm printing platform.

MISSE is a testing program designed to manufacture materials samples and secure them to a panel that will be mounted outside of the International Space Station to study the effects of outer space on 3D Printed products. 3DCERAM Sinto Inc will be making 20 sample parts to be launched to the space station for the MISSE program next year. The parts will be made as part of the evaluation process for ceramics that may one day be used on the outside of vehicles in space. The samples will remain there for six months in order to gain knowledge about the printed ceramic material’s ability to withstand the space environment. These tests will demonstrate the effects of in-space environmental exposures, such as zero gravity and radiation from the sun. Once these materials and manufacturing processes are characterized in space, flight worthy hot structures and heat shields could be printed on the 3DCERAM C1000 Flexmatic. The C1000 Flexmatic will allow NASA to print large and fully dense parts or many parts on the 320 mm x 320 mm printing platform.