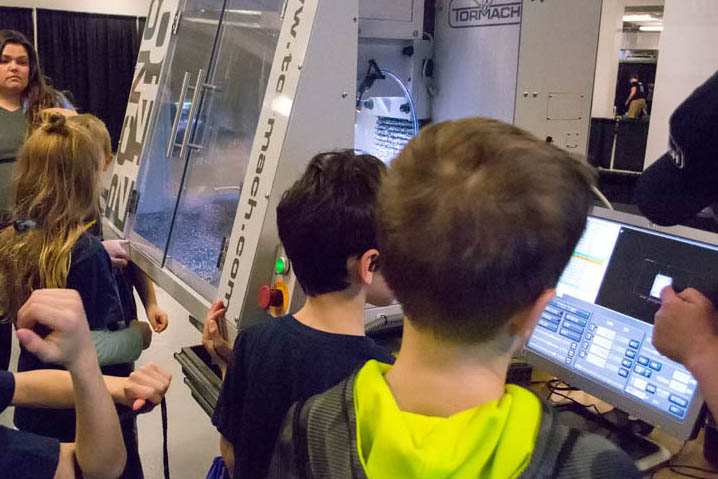

Letting students take control of the CNC machine for the first time each semester can be terrifying enough if they were paying attention to your wise words of caution, but we all know some of them weren’t taking studious notes. An easy way to save your machine and nerves is to give your students forgiving workpieces, like machinist wax, wood, or plastic, but that’s not always the best solution.

Letting students take control of the CNC machine for the first time each semester can be terrifying enough if they were paying attention to your wise words of caution, but we all know some of them weren’t taking studious notes. An easy way to save your machine and nerves is to give your students forgiving workpieces, like machinist wax, wood, or plastic, but that’s not always the best solution.

Students take your classes to learn about machining, and part of that includes feeds and speeds, tool geometry, and the basics of metallurgy for their workpieces. For beginner classes, those soft materials are great so they can learn how to control the machine, but, after that, let them learn the hard way.

Aluminum is a relatively cheap and soft workpiece material that can still make functional parts, such as brackets for FIRST Robotics teams, or structural components for Formula SAE teams. It also teaches the lessons you want to convey during lessons, such as identifying chatter and potential cutting tool damage, but with less risk of breaking things. Just to show you some numbers, I went onto Speedy Metals to compare prices of a few of common classroom materials:

- 1” x 2” x 4” Piece of Steel: $4.40

- 1” x 2” x 4” Piece of 2024 Aluminum: $9.96

- 2” Rod of White Nylon, 4” long: $10.48

- 1” x 2” x 4” Piece of 360 Brass: $25.88

- 1” x 2” x 4” Piece of 303 Stainless Steel: $26.88

To counter these prices, keep in mind your students have a higher chance of burning up a couple tools on the steel, as well as longer cutting times compared to aluminum, so the extra price usually is worth it. I’m a firm believer in students learning through consequences, like breaking tools and crashing machines, as long as there isn’t a lot of down time or cost associated with it.

To counter these prices, keep in mind your students have a higher chance of burning up a couple tools on the steel, as well as longer cutting times compared to aluminum, so the extra price usually is worth it. I’m a firm believer in students learning through consequences, like breaking tools and crashing machines, as long as there isn’t a lot of down time or cost associated with it.

This may be a pie in the sky motto – since it normally includes a larger budget and lots of time to babysit students – but if you can find one or two times a semester for each student to learn these lessons, the more understanding students will leave your classroom with. And that’s always the goal, right?

About Tormach

At Tormach, their mission is to empower people who make things. They are dedicated to providing exceptionally engineered small CNC machines, tooling, and related products with best-in-industry technical support and customer service. Their focus is to help their customers turn their concepts in to reality by providing the tools and information that help them be successful with CNC. Their flagship products include the PCNC, or Personal CNC, series of machine tools. PCNC mills have become the CNC machine of choice for inventors, small/boutique manufacturers, garage entrepreneurs, product developers, hobbyists, educators, and people who make things around the world.

Their company has grown quite a bit from modest beginnings. Like many of the businesses that use our PCNC machines, Tormach was started in garage – not too far from their current shop near Madison, WI. Back in 2001, two friends had a series of casual conversations, basically maligning how there were no good small CNC machines available for inventors, R&D professionals, or small manufacturers. Both had expertise in manufacturing automation: one of the two owned a specialty tool company, and the other was general manager of a technology research company. Both agreed they could really make use of an affordable small CNC machine, whether for prototyping products or for specialty manufacturing ,if only such a machine existed. They came up with the concept of Personal CNC – paying homage to some of the same ideas that spawned the personal computer revolution in the late 1970s, and began to put together a list of design criteria for a PCNC.