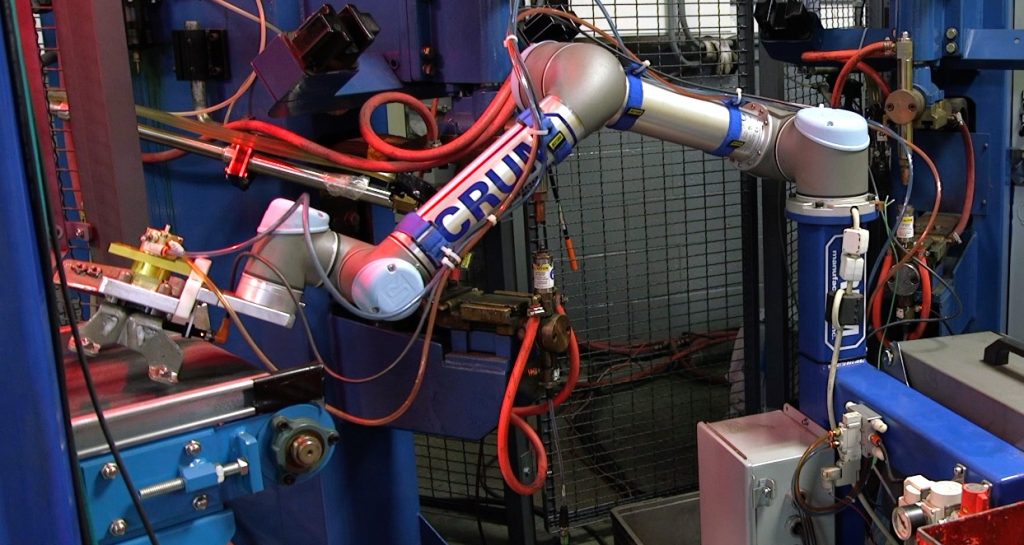

T&W Stamping in Ohio wanted to automate one of the most labor-intensive parts of its metal fabricating process: the tending of resistive welders. This is a tricky application to automate due to the welding equipment’s electro-magnetic pulse that blank out robots’ servo motors. The company solved the issue with a UR5 cobot that paid for itself in less than four months, delivering 40% increase in efficiency and freeing up three operator functions. “Using collaborative robots to tend resistive welders? To the best of our knowledge, this was not something anyone in the industry had done before,” says Juan Rodriguez, Director of Automation with Crum Manufacturing, a Certified Systems Integrator of Universal Robots.

He was working with T&W Stamping in Youngstown, Ohio, a contract manufacturer primarily for the heavy-duty truck market who was in need of a reliable automation solution. “We had just received a contract from a large customer of ours to manufacture powertrain brackets,” says Craig Sivak, Executive Vice President & General Manager, T&W Stamping. “Volume on it wasn’t huge—about 40,000 parts per year—but each part has eight weld nuts, so that’s 320,000 welds that we would otherwise have to do manually.” Sivak and his team decided to investigate whether collaborative robots could handle the task. “With a cobot, we could keep our existing layout as we didn’t need additional guarding around the cobot due to its built-in safety system,” he says.

While it is common for large industrial robots to perform resistive welding, Rodriguez explains why this is not an application that small collaborative robots have historically handled.

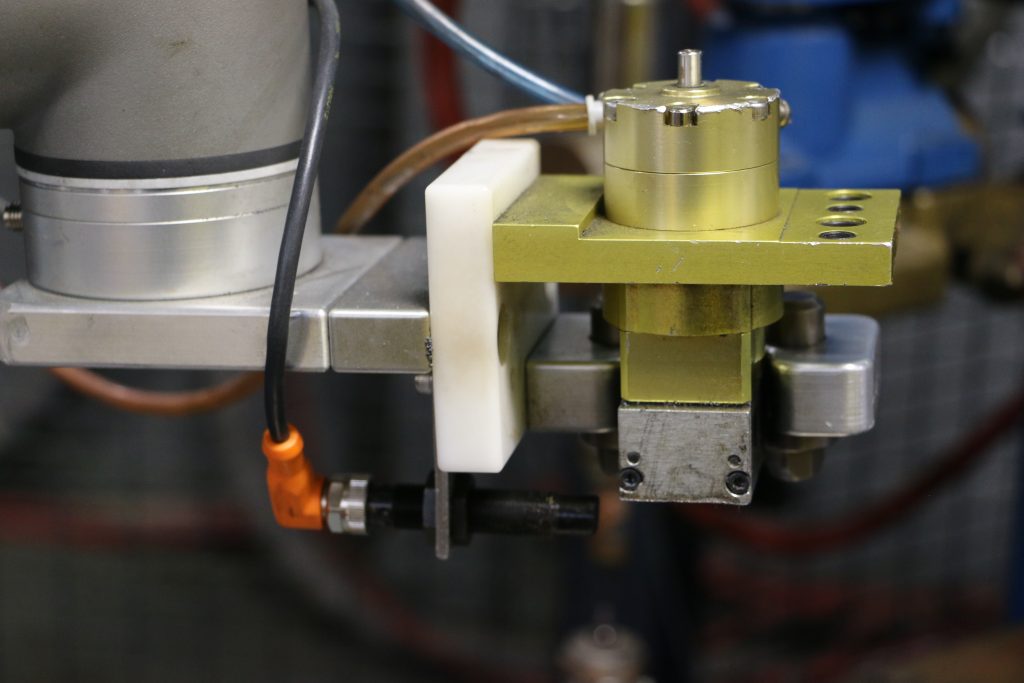

“Resistive welders set off an EMP (electro-magnetic pulse) that blanks out any kind of electronics in a certain radius. That’s not an issue with traditional robots with big C-clamp end-of-arm tools where the robot is extremely far away from the point of strike,” he says. “But with a small cobot that you try to fit nicely into an existing cell? That’s a very different story.” Crum Manufacturing overcame this obstacle by grounding the robot and adding a non-metallic material to the custom-made end-of-arm-tooling which distanced the robot farther from the welder (see sidebar for more info).

Stunned at The Low Cost

Being able to use collaborative robots for this tricky task was not the only pleasant discovery at T&W Stamping. “As our engineers gave us the initial quotation for the Universal Robot itself, we were stunned at the cost,” says Sivak. “When looking at some of the larger robots, they’re six figures; we were expecting a much larger number.” T&W Stamping was able to implement the entire cell for 30 percent less than the company would have spent on eight separate fixtures to position the part to present it to the welder. The contract manufacturer also freed up three operator functions. “We’re in the neighborhood of 40 percent more efficient than we normally would have been,” said Sivak who also did the ROI calculations.

“When we factored in the cost savings that we didn’t have in the other fixtures—and more importantly, the labor dollar and benefits saved with less operators—payback was less than four months.”

Vision-Guidance Ensures Exact Welds

The cobot carrying out the cost savings is Universal Robots’ mid-size model, the UR5, boasting an 11-pound payload and a reach of 33.5 inches. “The UR cobot picks the part up right on the datum point, which is very important because it’s being the fixture for the part itself,” explains Sivak. “Once the UR robot picks up the part, it knows exactly where each and every hole location is.”

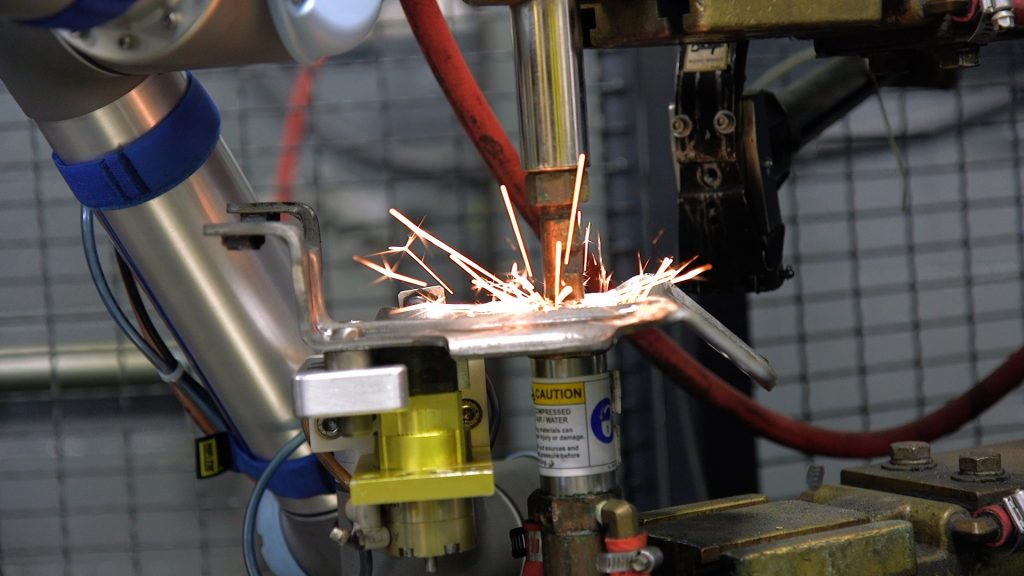

The part picking is guided by a vision camera from Cognex above the conveyor. With that guidance, the UR5 places the part in the first of two G.E. Schmidt resistive welders, which carries out the first four welds as weld nuts are placed on the part by a vibratory nut feeder. If the bolt comes out upside down or is missing, the welder has a tip that senses this and accommodates by sending a signal through a PLC to the robot to discard that bolt and have another one shot over. After the first four welds are performed, the UR5 rotates the bracket and moves it to the second welder that completes the final four welds. The reason to split the cycle between two welders is to keep the welders from overheating. The 52-second cycle concludes as the UR5 moves the part to a second Cognex camera above the outbound conveyor that checks that the part has all eight weld nuts, that they’re in a correct position, and that they all have threads.

Product Consistency With No Downtime

T&W Stamping runs eight-hour shifts, five days a week. The UR5 typically operates at 60 percent capacity and has been in operation for more than two years. “The benefit that we see from installing the UR robot really is consistency. It does a fantastic job,” says Sivak. “We haven’t had any production issues or downtime with it. If we didn’t have the robot, there would be four operators in that cell managing the eight fixtures to get the weld nuts on that part.”

Developing the robot cell for T&W is an accomplishment Juan Rodriguez does not hesitate to call a homerun. “These resistive welders are more than 30 years old. Being able to find a way to interface these with brand new cobot technology is a big win both for us and the company,” he says. “We will definitely see more integration of Universal Robots with resistive welders and with welding equipment altogether.”

Redeploying the Workforce

Installing the UR5 also meant that T&W employees got a new type of colleague working side-by-side with them. “Initially, our operators may have been a little nervous, but once they got into the cycle, it’s worked out well for both us and the workforce, as they are now off doing other more value-added operations,” says Sivak, emphasizing how the cobot has empowered the employees. “The cobot has given them challenges they haven’t had before. After the training, they just hit the ground running and have done really well with it.”

Operator Frank Fowler used to weld the brackets by hand. Instead, he is now programming the robot and is in charge of product inspection. “As far as interfacing with the robot, I must admit I was a little overwhelmed,” he says, adding he has no background in robotics but learned the basics in a three-day training course. “It seemed like a lot to take in, but the robot is actually user-friendly, and I enjoy working with it. It’s a less monotonous process now and it’s neat to watch all the systems interact with each other.”

Next application: UR5 performs MIG welding

Having gained confidence with Universal Robots from the first application, T&W Stamping has now started to look at new tasks that cobots could handle. “We produce oil pans with components resistance-welded into them. Because of the size and configuration of the part, it would be very difficult to automate with resistance welders,” says Sivak who is instead looking at MIG welding. “Our intention is to use a UR robot to fixture the components into the part, as well as put a torch on one and do the MIG welding with that,” he explains. “This will be a new process for the robot as opposed to what it’s doing today, as it will actually be doing the welding itself.”

How Crum Manufacturing Solved the EMP Issue

How Crum Manufacturing Solved the EMP Issue

Roxanne. That’s the nickname the engineers jokingly started calling the UR5 robot as it kept “putting on the red lights” when it repeatedly faulted as the resistive welders set off the electro-magnetic pulse (EMP) signal that would wipe out the encoder count in the cobot’s servo motors, making it lose position. Humor aside, the headache was real as Crum Manufacturing headed into unknown territory, trying to figure out how to troubleshoot the EMP issue. “It was steps,” says Juan Rodriguez, Director of Automation at Crum Manufacturing, a Certified Systems Integrator (CSI) of Universal Robots. “We would back the robot up ten millimeters, fire the resistive welder—did the cobot fault, did it not fault? We had to go in those increments to find out how far away we had to be from the welding tip to pinpoint the true issue.” Once the Crum team located the distance, it was back to the drawing board. “An easy fix would be to say, ‘All right, just make my end-of-arm tool 12 inches longer to keep it away from the welding tip,’” says Rodriguez. “However, a Universal Robot is designed for the center of gravity calculation, meaning a UR5 can pick up five kilograms at the faceplate. The farther you get away from that faceplate, the more that curve goes down and we would start damaging the robot.” Crum solved the distance by adding a light-weight, non-metallic insert between the robot’s face plate and a magnetic grip part from Magswitch. Next was figuring out how to properly ground the UR5 in a heat environment. “We really went above and beyond to make sure the robot was grounded and used a copper line. This is really important in applications with any kind of noise or interference issues,” says Rodriguez.

About Universal Robots

Universal Robots was co-founded in 2005 by the company’s CTO, Esben Østergaard – the 2018 Engelberger Award Winner – who wanted to make robot technology accessible to all by developing small, user-friendly, reasonably priced, flexible industrial robots that are safe to work with. Since the first collaborative robot (cobot) was launched in 2008, the company has experienced considerable growth with the user-friendly cobot now sold worldwide. The company, which is a part of Teradyne Inc., is headquartered in Odense, Denmark, and has subsidiaries and regional offices in the United States, Germany, France, Spain, Italy, Czech Republic, Turkey, China, India, Singapore, Japan, South Korea, Taiwan and Mexico. In 2017, Universal Robots had a revenue of USD 170 million.

About T&W Stamping

T&W Stamping in Youngstown, Ohio, specializes in deep drawn and heavy gauge steel, stainless steel, and aluminum products. The company serves global OEMs in the medium and heavy-duty truck, bus, aerospace, construction and marine markets in Americas, Europe and Asia. T&W Stamping is one of the world’s largest producers of steel oil pans, transmission pans, and sump covers.