Every aspect of manufacturing operations continues to grow in complexity, presenting challenges at every turn—and learning to manage this complexity is essential to success. As we witness the evolution of industrial machinery from automated production lines to adaptive, flexible, connected production facilities, it becomes evident that the integration of autonomous, self-optimizing machinery throughout manufacturing is reshaping the way machines are designed, built and operated.

This new approach to manufacturing can be summarized by the term “smart factories” – which in turn drives the need for smart machines. Machine builders must invest in new technologies to meet these evolving customer demands – but this paradigm shift also creates a high demand for workforce skills that are in short supply. Amidst this uncertainty, there emerges the pressing need for a strategic approach to simplify technical challenges and allow the assimilation of technological and process change.

In this article, we will examine the three fundamental pillars—electrification, automation and digitalization—that not only enable but also provide new approaches to simplifying technical issues for machine builders. To meet the smart manufacturing requirements of customers, machine builders must transform their approach to design, engineering, manufacturing and field support. This transformation is an opportunity to grow business, improve sustainability, and deliver financial predictability.

By embracing repeatable processes enabled by these pillars, manufacturers can meet future demands with confidence and agility, ensuring continued success in an ever-changing landscape.

Electrification: Powering sustainable solutions

Manufacturing is challenged with rising energy costs, along with a drive to meet increasingly demanding sustainability regulations. The integration of sensors into machines resulting from initiatives such as Industry 4.0 and the Industrial Internet of Things (IIoT) helps companies to effectively manage energy use, improve operational efficiency and reduce waste. The ability to measure and quantify improvements supports sustainability goals.

Electrification offers huge opportunities to drive efficiency improvements into manufacturing operations. The ability to measure actual energy consumption, combined with simulation tools to illustrate the benefit of process change and equipment upgrades, can help to justify investments. Modern electric-powered machinery operates with great precision and reliability, leading to smoother production processes, reduced energy consumption and lower maintenance costs.

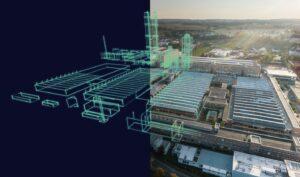

A digital twin can be created at the factory or machine level, raising understanding of production processes and identifying prime areas for improvement. Machine performance can benefit from the selection of high efficiency electric motors, variable speed drives, and actuators with advanced control algorithms. Simulation can help to improve robot efficiency through path planning and gripper optimization.

Machine sensors support a transformation in the way machines are maintained. These sensors can deliver real-time, accurate measurements of operational parameters that provide visibility of a machine’s condition. We will discuss this in more detail in the third pillar, digitalization.

Automation: Increasing productivity

In addition to a workforce shortage and sustainability concerns fueled by the global climate crisis, the industrial machinery industry is experiencing new levels of competition. Customers expect better products at an expedited rate, leaving machine builders to search for solutions that allow them to produce products faster while maintaining quality—and increasing factory automation is one way manufacturers can remain ahead of the competition.

Automation eliminates repetitive manual tasks, reducing the risk of errors and ensuring consistent quality. From assembly lines to packaging, robots and smart machines work tirelessly, boosting overall efficiency. Employees can focus on higher-value tasks, reducing physical strain. Automation enhances workplace ergonomics and overall well-being.

Machine builders are transitioning from traditional mechanical reliant designs to integrated mechatronic-based approaches, where mechanical, electrical and automation design activities seamlessly converge. This multi-domain approach benefits greatly from the creation of a digital twin encompassing entire machines and workflows. The digital twin allows a machine builder to improve overall performance in the virtual world before building a physical machine.

Moreover, advancements in technology are redefining internal operations, enhancing agility and responsiveness. Real-time monitoring capabilities enable adaptive modifications, optimizing equipment functionality in real-world scenarios. This proactive approach not only minimizes downtime but also fosters continuous improvement.

While initial investment in automation might seem high, long-term savings are substantial. Reduced labor costs, fewer employee-related expenses, and minimized downtime contribute to a healthier bottom line.

Digitalization: Turning data into insights

Electrification and automation pave the way for companies to embrace and implement digitalization. By harnessing the power of digital technologies such as AI, machine learning (ML) and IT, manufacturers can gather, analyze and leverage data to drive informed decision making from top floor to shop floor.

In the electrification pillar, we introduced machine sensor data. The integration of AI tools to analyze this data can deliver new opportunities to machine builders through the adoption of new service strategies such as condition and predictive maintenance. Notifications of changing parameters can be generated, prompting the machine builder to investigate and diagnose using secure remote monitoring tools. Problems can sometimes be affected through software updates, but should a service activity be required, the field technician can be dispatched with the correct tools, parts and repair instructions before a problem impacts production.

It is vital to continually evaluate the electrical and behavior model of machines within the context of the factory to discover the impact of any proposed changes across the more extensive operation. The simulation capabilities for industrial systems encompass the component, machine, and plant levels, providing many tools to the customer to evaluate the entire performance of a production plant, from production planning to actual operations.

Initially, simulation enables the creation of a digital twin of the machine during the design process, which is used to explore a broader range of design possibilities and virtually prototype them. Then, this digital experience generated in the design process is maintained over the machine operation’s lifecycle, merging the physical and digital versions of the machine and process. During machine operation, real-world data is fed back into the machine’s digital twin to optimize the twin’s fidelity. It is possible to explore “what if” scenarios for improving machine quality or line modifications before committing to actual changes. Equally important, it provides a way to optimize continuously for sustainability over the lifecycle of the machinery.

Navigating complexity with confidence and agility

As manufacturers face the ever-growing challenges of sustainability, changing workforce skills, and increasing competition, the pillars of electrification, automation and digitalization help them gain the tools they need to navigate hurdles with confidence and agility. By embracing repeatable processes and implementing new technology into factories and processes, they can streamline operations, drive sustainability and above all, simplify the technical challenges of the smart factory.

About the author

Rahul Garg is the Vice President for Industrial Machinery and SMB Program at Siemens Digital Industries Software, responsible for defining and delivering key strategic initiatives and solutions, and global business development. He and his team are responsible for identifying key initiatives and developing solutions for the industry while working closely with industry-leading customers and providing thought leadership on new and emerging issues faced by the machinery industry. Rahul’s experience and insight are derived from a 25-year career delivering software-based solutions for product engineering and manufacturing innovation for the global manufacturing industry, spanning a career in R&D to program management, sales and P&L management and having focused exclusively on the industrial machinery and heavy equipment industry since 2007.

Rahul Garg is the Vice President for Industrial Machinery and SMB Program at Siemens Digital Industries Software, responsible for defining and delivering key strategic initiatives and solutions, and global business development. He and his team are responsible for identifying key initiatives and developing solutions for the industry while working closely with industry-leading customers and providing thought leadership on new and emerging issues faced by the machinery industry. Rahul’s experience and insight are derived from a 25-year career delivering software-based solutions for product engineering and manufacturing innovation for the global manufacturing industry, spanning a career in R&D to program management, sales and P&L management and having focused exclusively on the industrial machinery and heavy equipment industry since 2007.