Traditional plate or shell and tube heat exchangers have long been used in processing industries. Today, however, with many new applications involving high pressures, temperatures, and exposure to corrosive environments, more manufacturers are turning to compact printed circuit heat exchangers (PCHEs).

A PCHE is a multi-layer heat exchanger consisting of thin, flat metal plates into which fluid flow microchannels are chemically etched in each layer to form a complex flow pattern. The layers are then diffusion bonded together to create a dense heat exchanger with superior airflow and heat transfer properties.

When designed this way, a heat exchanger can be up to 85% smaller and lighter than traditional plate or shell and tube designs. In addition, PCHEs do not require excessive pipework, frames, or other associated structural elements, further reducing costs.

“A high-quality diffusion bonded PCHE can withstand very high pressures of hundreds of bars and extreme temperatures beyond 800°C. As a result, PCHEs are well suited for a wide range of demanding applications, including oil and gas, hydrogen vehicle fueling stations, and aerospace,” says Dr. Udo Broich, Managing Director of PVA Industrial Vacuum Systems GmbH, Wettenberg, Germany. Dr. Broich, who wrote his doctorate thesis on joining technology, has focused on vacuum brazing and diffusion bonding for 25 years. PVA TePla AG is a global manufacturer of industrial furnaces and PulsPlasma nitriding systems.

Diffusion bonding versus brazing

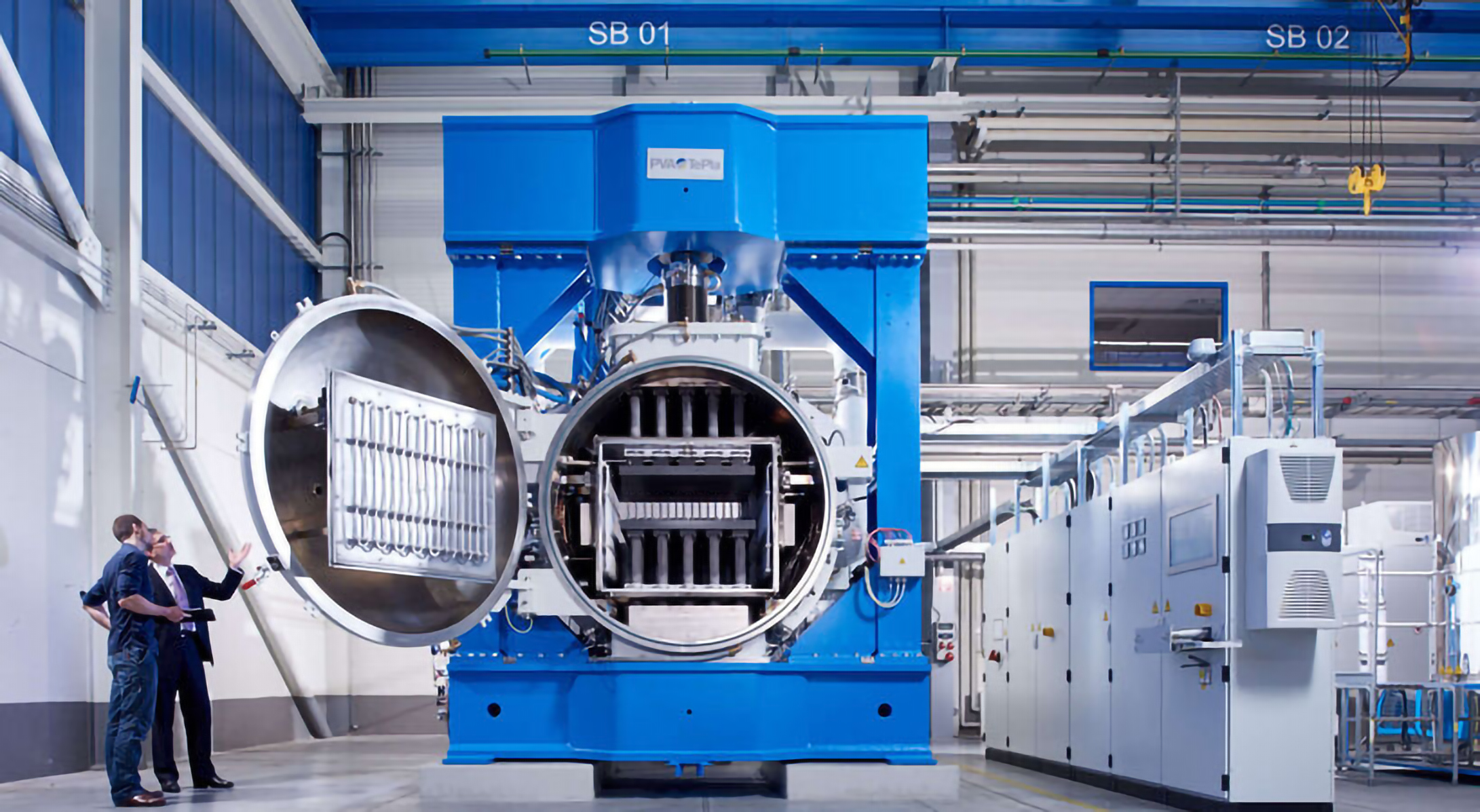

For many years, diffusion bonding has been utilized to join high strength and refractory metals that are either difficult or impossible by other means. The process involves applying high temperature and pressure to the bonding part in a high vacuum hot press like those offered by PVA TePla; this causes the atoms on solid metallic surfaces to intersperse and join. The final piece will have little or no interface lines or striations if the materials are similar; the interface of one material blends into the other, and vice versa. The same result can also be achieved with dissimilar materials with the right equipment, material preparation, and process.

The key to the process is utilizing diffusion bonding to join the layers over other alternatives, such as vacuum brazing. Although brazing is widely used for joining metals under normal conditions, it can be insufficient in high temperature, pressure, or corrosion situations. Brazing is a joining process in which two or more metal items are joined together by melting and flowing a filler metal into the joint. The filler metal flows into the gap between the layers through capillary action.

With a proper choice of filler material and process parameters, brazing can also create high strengths and thermal resistant joints. However, as the filler metal always has a different chemical composition from the bonding part materials, the properties of brazed components usually cannot reach that of a solid part., according to Dr. Broich.

“In the case of brazing a PCHE, engineers must consider another issue: during brazing, molten filler metal can penetrate the microchannels and solidify, blocking the channels required for airflow. This can render the PCHE quite ineffective,” says Dr. Broich. “Since diffusion bonding requires no filler metal and is a solid-state joining process, the microchannels remain intact.”

“When the layers of a PCHE are diffusion bonded, the final product retains the parent material’s mechanical, chemical, and thermal properties. Given the high strength and integrity of the material, PCHEs can withstand very severe operational conditions,” explains Dr. Broich.

A significant advantage of diffusion bonded PCHEs is that it significantly reduces the size of the heat exchanger.

“PCHEs have about 85% less mass and volume than traditional heat exchangers, while the microchannels provide a large surface area for heat exchange,” says Dr. Broich. “Achieving the same heat transfer rate with a standard [plate, or shell and tube] heat exchanger] design requires much more mass and volume.”

Growing Markets for Diffusion Bonded PCHEs

Due to the inherent advantages of diffusion bonded PCHEs, many industries are adopting this evolving technology to improve heat transfer in various applications.

Oil and Gas

The compact, efficient heat transfer capabilities of PCHEs are ideal for many oil and gas applications, including preheaters, superheaters, gas compression coolers, high-temperature recuperators, and liquified natural gas (LNG) exchangers.

For example, in offshore LNG production, natural gas is converted to a liquid for safe transport or storage when pipelines are not available. LNG takes up only a fraction of the space in its liquid form, but the natural gas must be cooled to approximately -260°F as part of the process, generating heat. A PCHE is a practical, compact solution for small footprint areas like onboard ships.

Hydrogen Fueling Stations

PCHEs are a requirement in hydrogen vehicle fueling stations. Stored hydrogen must be pre-cooled to approximately -40°C before being transferred into the vehicle’s tank. This cooling process prevents potential damage from the excessive temperature that can damage tanks during filling.

“To fill a tank, pressurized hydrogen is dispensed at roughly 1,000 bars; this process generates excessive heat,” says Dr. Broich. “Because it is critical that the temperature not exceed the critical limits of the tank, hydrogen is pre-cooled to about -40°C. The PCHE in the fueling station’s cooling loop must withstand 1,000 or more bars of pressure and temperatures as low as -50°C. The compact design of PCHEs also eases integration with the hydrogen dispenser casing.”

Aluminum Heat Sink Applications: Electric Vehicle and Aerospace

Aluminum heat sinks are popular for the thermal management of many critical devices where weight is a factor, including automotive and aerospace. Aluminum heat sinks are also commonly used with electric batteries.

The most common aluminum alloys used in heat sinks and exchangers are the 6000 series alloys. However, magnesium and silicon are the primary alloying elements and are difficult to join with methods such as brazing.

“In many heat sink applications, brazing flux is often prohibited. Therefore, vacuum brazing remains a joining technology using filler metals based on an aluminum-silicon eutectic alloy. However, these alloys have a melting point of 580°C, very close to the melting point of the base material, thus providing only a tiny process window to achieve high-quality bonds,” says Dr. Broich.

He notes that PVA TePla has developed a diffusion bonding process to successfully join high alloyed aluminum materials like 6061 over the years.

Optimizing Furnace Design for Diffusion Bonding

There are various approaches to furnace design and process implementation for diffusion bonding of PCHEs. Advances in high vacuum furnace hot presses allow superior pressure control and rapid cooling systems that improve bonding, increase yields, and significantly decrease cycle time.

Manufacturers such as PVA TePla offer multi-cylinder systems with large pressing plates that accommodate various parts. The largest, the company’s MOV 843 HP, can process substrates as large as 950mm (37.4”) x 1300mm (51.18”), which is quite a large area for diffusion bonding. The pressing force is 8,000 kN. Research is underway to increase this geometrical limitation as well.

The integrated press provides remarkably consistent pressure across the entire surface by controlling and synchronizing each cylinder. The MOV also comes with built-in pressure transducers along the bottom of the pressing plate. The individual hydraulic cylinders can be adjusted in the software to achieve uniformity even over large areas based on sensor feedback.

Dr. Broich points out that high-bonding strength is critical for applications involving PCHEs in extreme settings.

“It requires a high-strength design [when a high vacuum hot press is needed] of the pressing unit [pressing rams and platens) to transfer 800 or 1000 tons at 1,000°C or even higher temperatures,” says Dr. Broich.

In addition, the pressing unit should have a design that minimizes the mass within the hot zone while achieving uniform force distribution throughout the working space and pressing plate, according to Dr. Broich.

“The design of a diffusion bonding machine should enable the shortest cycle times possible while saving energy by reducing its thermal mass; this is very important to productivity and cost-effectiveness,” he points out.

To produce a high-quality diffusion bonded PCHE, working with an expert partner like PVA TePla can be essential for manufacturers that require process and technology support.

“Most of our customers are not familiar with this technology. We support them with basic process technical knowledge so they can correctly use the machine to produce a high-quality diffusion bonded PCHE,” says Dr. Broich.

Due to the rapidly expanding need for this precision technology in the U.S., PVA TePla is opening a diffusion bonding technology center in Corona, California. This summer, a full-scale industrial furnace that matches the capabilities offered in Germany will be available. PVA TePla will be able to demonstrate the machine’s bonding capabilities, run R&D samples, and provide processing services.

“In both the U.S. and Germany, we can demonstrate the quality of the bonds before a customer decides to invest in a machine. We handle most of the elements of process development to prove the technology and assist in scaling up to production volumes. Alternatively, we can provide full-scale contract processing for customers if they outsource production,” says Dr. Broich.