Volatility in the oil market is forcing drilling and production companies to search every nook and cranny of their operations for ways to improve efficiency.One often-overlooked area that can have an impact is threading operations used to produce couplings. A switch from the push method to a pull method can increase efficiency by more than 50 percent.

Volatility in the oil market is forcing drilling and production companies to search every nook and cranny of their operations for ways to improve efficiency.One often-overlooked area that can have an impact is threading operations used to produce couplings. A switch from the push method to a pull method can increase efficiency by more than 50 percent.

Pushing the Tradition

Threading operations are crucial in the oil and gas industry. When oil production is high, companies need to produce as many pipe couplings per day as possible. In tougher times when production is down, pressure mounts to improve labor efficiency. Threading operations are both demanding and labor intensive. The traditional push method with right-hand tooling systems requires an operator to make multiple passes which, in turn, makes cycle times long.

Unique applications in oil drilling require couplings with precision threading. Long steel pipes connected by couplings create “strings” that reach deep in wells. The extended length of these lines and fact that they are not easily accessible once placed in the well means the couplings must be extremely reliable.

Unique applications in oil drilling require couplings with precision threading. Long steel pipes connected by couplings create “strings” that reach deep in wells. The extended length of these lines and fact that they are not easily accessible once placed in the well means the couplings must be extremely reliable.

Hostile environmental conditions in the oil and gas industry further complicate matters. Pipes and couplings used in oil drilling applications must withstand harsh conditions from deep within the earth’s crust. To combat problems with corrosion, oil companies have begun using tougher materials such as Group 4 and P10 steel and higher cobalt compositions to produce couplings, which makes threading operations even more challenging.

The oil industry primarily uses two types of thread forms: the 8 API/RD frequently used in shallower wells, and buttress threads, which are designed for superior hydraulic seals. To produce an 8 API/RD thread using push threading normally requires a minimum of two passes. Buttress threads typically require a minimum of three to four passes.

In addition to being time intensive with multiple passes, the push method of threading is also labor intensive. The natural build-up of long, stringy chips during push threading requires manual removal by an operator. If not removed during the process, these chips will be re-cut, causing unnecessary tool wear and slower cycle times. To avoid complications, between passes operators must stop production to clear chips. This is normally done by sticking a hook down into the coupling to pull the chips out and away from the part before restarting the cycle.

Pulling in a New Direction

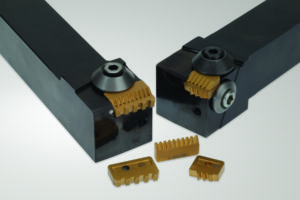

Pull threading is an improved method for threading pipe couplings developed by Seco Tools, which allows threads to be created with just one or two passes. The process features the Thread Chaser, a left-hand tooling system with multi-tooth, chaser-style threading inserts that are pulled through to direct cutting forces into the beds of the turning centers used to machine the couplings using inserts that are designed for reliability and wear resistance at higher cutting speeds.

Thread Chaser was specifically designed to handle tougher materials now commonly used to produce the robust couplings required in the oil and gas industry. It features a special substrate material for hardness and long tool life. The system’s strong holder and clamp securely hold the insert in place and withstand the unique pressures created from the pulling action.

to produce the robust couplings required in the oil and gas industry. It features a special substrate material for hardness and long tool life. The system’s strong holder and clamp securely hold the insert in place and withstand the unique pressures created from the pulling action.

Chasing Savings in Cycle Times

The pull threading method increases productivity by generating the thread teeth, facing and taper at the same pitch as the thread type. It also enhances productivity by efficiently removing chips which eliminates the need to interrupt production cycles. During production, the system pulls the chips out of the coupling and drops them into the machine tool’s chip bed so they don’t pack back into the coupling ID. To further aid in chip removal, the system uses high-pressure coolant to break the chips down. Instead of large, stringy chips that can cause safety issues and major problems with machine tools, Thread Chaser breaks long chip strings into segments 1/2″ or smaller.

chip strings into segments 1/2″ or smaller.

In some applications, the pull system can reduce cycle times to as little as 20 seconds, just one-third of a typical one-minute cycle using push methods. When oil companies are in high-production mode, producing hundreds of thousands of couplings each month, the increased productivity adds up to significant timesavings. And when demand for couplings is lower due to lower oil production levels, every step toward higher efficiency can help minimize the impact of challenging times.

For more information, visit www.secotools.com