As demand for 3D-printed parts in industries such as aerospace, medical, and consumer products continues to grow, manufacturers are under pressure to optimize production workflows and maintain consistent quality. Prototek, a leader in additive manufacturing, produces around 20,000 resin-based parts each month using cutting-edge 3D printing technologies. However, Prototek encountered significant challenges with the traditional resin post-processing methods, which ultimately led them to adopt an advanced solution from PostProcess Technologies.

The Challenges of Traditional Resin Post-Processing

Initially, Prototek relied on traditional isopropyl alcohol (IPA) dunking methods for removing resin from parts. This method, while common in additive manufacturing, presented a range of challenges that impacted both efficiency and quality. Some of the main issues included:

Inconsistency in Cleaning: Resin removal via IPA baths often resulted in inconsistent outcomes due to variances in solvent concentration and the quality of the dunking process. Manual processing, especially in high volumes, led to variability in the surface finish and mechanical properties of the printed parts.

High Solvent Costs and Environmental Impact: Frequent replacement of IPA was necessary to maintain effectiveness. Not only did this contribute to increased operational costs, but the use of large quantities of IPA also raised concerns regarding environmental impact and workplace safety due to the volatility of the solvent.

Quality Control Issues: Variability in IPA concentration and temperature could lead to under-processed or over-processed parts. Insufficient resin removal resulted in compromised part quality and appearance, while over-processing could damage delicate features, making it challenging to maintain a consistent output.

Manual Labor and Time Consumption: The reliance on manual intervention to monitor and execute the dunking process was time-intensive and laborious. A single job required dedicated time and focus from skilled operators, who had to manage multiple variables to achieve the desired finish.

These limitations drove Prototek to seek a more robust, efficient, and scalable solution to meet its growing production needs. After evaluating several options, Prototek selected PostProcess Technologies’ DEMI 910™ automated resin removal solution to address these challenges.

Why Prototek Chose the DEMI 910™

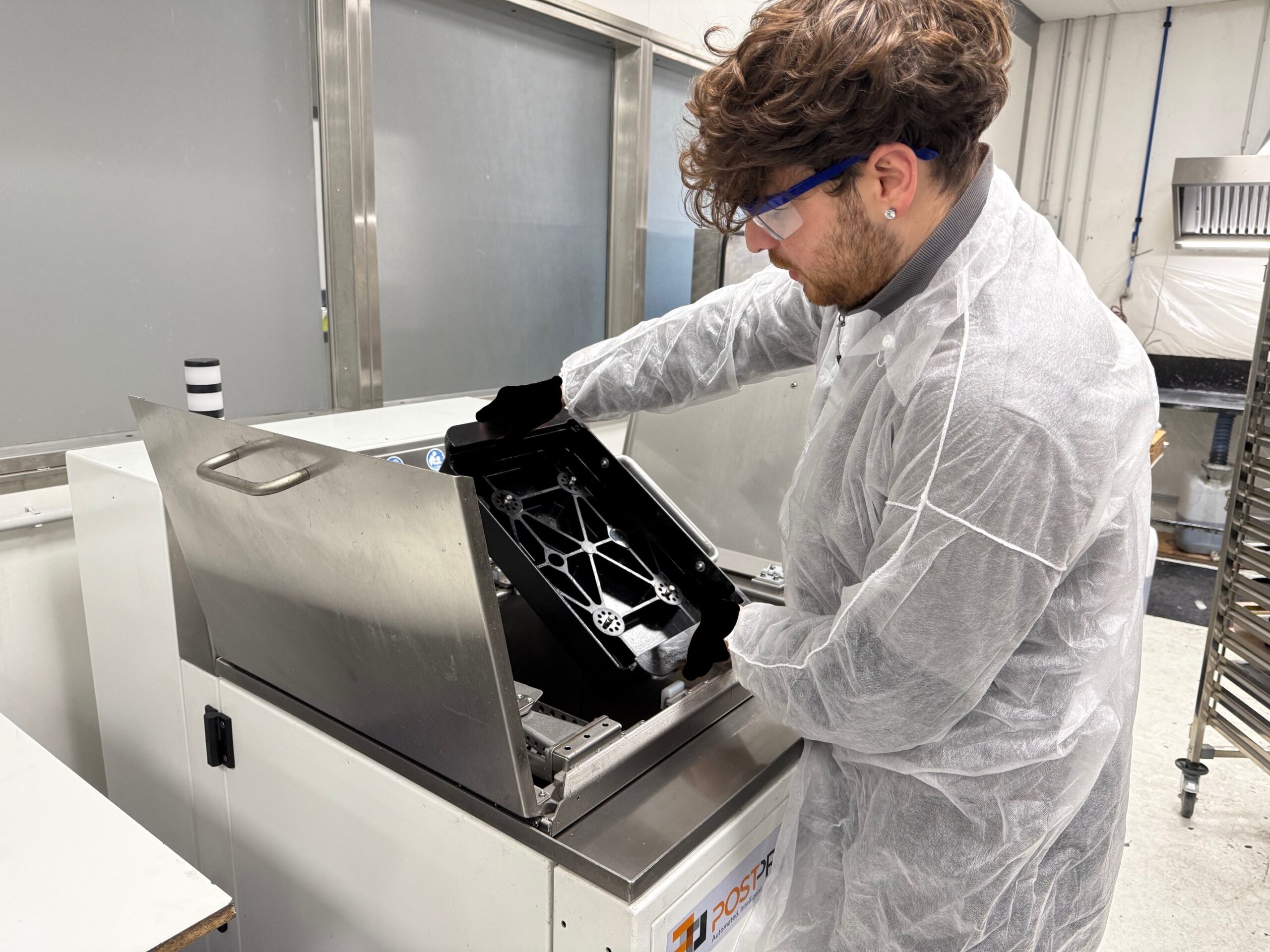

The DEMI 910™, developed by PostProcess Technologies, represented a significant advancement in automated post-processing for resin-based parts. Unlike traditional solvent-based methods, the DEMI 910™ offered a closed-loop, automated solution that mitigates the issues associated with IPA dunking. Key features of the DEMI 910™ that made it the ideal choice for Prototek include:

Automated Resin Removal: By automating the entire resin removal process, the DEMI 910™ minimized human error and manual intervention, allowing Prototek’s operators to focus on other high-value tasks.

Precision with PLM-501-SUB Detergent: The DEMI 910™ uses PostProcess Technologies’ proprietary PLM-501-SUB detergent, specifically formulated for elastomeric resin removal. Unlike IPA, PLM-501-SUB is engineered to remove resin at a consistent rate without losing efficacy over time. This contributed to more predictable and repeatable outcomes.

Enhanced Throughput: The DEMI 910™ allowed Prototek to process up to three jobs simultaneously, drastically reducing cycle times. With a processing capability of one job per hour, Prototek was able to achieve nearly triple the throughput compared to the previous method, significantly enhancing productivity.

Compatibility with Carbon® L1 Printers: Prototek’s adoption of the DEMI 910™ was driven in part by its compatibility with Carbon® L1 printers. These printers are widely used for high-volume, high-quality parts, and the DEMI 910™’s advanced automation features seamlessly integrated with Prototek’s existing infrastructure.

Streamlined Workflow and Improved Efficiency

Prototek’s transition to the DEMI 910™ resin removal system brought immediate improvements in workflow and efficiency. Before implementing this solution, Prototek faced significant bottlenecks in post-processing due to the manual labor required to monitor and adjust the IPA concentration and temperature for each batch. The automated capabilities of the DEMI 910™ allowed Prototek to eliminate these bottlenecks by providing a hands-free solution.

By reducing the need for constant human oversight, Prototek’s team could allocate their time to other essential tasks, such as quality control, part finishing, and machine maintenance. This shift not only improved the company’s efficiency but also resulted in a more streamlined operation, allowing for faster turnaround times and more predictable schedules for customers.

Boosting Consistency and Quality Control

The consistent output from the DEMI 910™ addressed the quality control issues Prototek previously encountered with IPA-based methods. Thanks to the PLM-501-SUB detergent’s stability, Prototek was able to achieve reliable, high-quality finishes without risking damage to the parts. The controlled environment within the DEMI 910™ prevented issues related to temperature fluctuations and solvent degradation, which are common in traditional dunking methods.

Additionally, the automation provided by the DEMI 910™ allowed Prototek to maintain uniformity across multiple batches of parts. This consistency was especially important for Prototek’s clients, who require precision in their components, whether they are used for medical applications or intricate consumer products. With a reliable, repeatable process in place, Prototek established a strong foundation for quality assurance and customer satisfaction.

Sustainability and Cost-Effectiveness

Beyond quality and efficiency, Prototek also considered the environmental and economic benefits of adopting the DEMI 910™ system. The PLM-501-SUB detergent’s extended lifespan and lower volatility reduced the frequency of replenishment and the costs associated with solvent disposal. Unlike IPA, which can evaporate quickly and must be frequently replaced, the closed-loop system in the DEMI 910™ minimized solvent waste and improved overall sustainability.

By transitioning away from IPA, Prototek also reduced its reliance on flammable solvents, creating a safer and more eco-friendly work environment. These changes not only contributed to cost savings but also aligned with Prototek’s commitment to environmental responsibility, an increasingly important factor for many manufacturing businesses today.

Future Outlook and Potential for Scaling

Prototek’s success with the DEMI 910™ resin removal system has encouraged the company to consider additional applications for PostProcess Technologies’ solutions. The scalability and flexibility of the DEMI 910™ open new possibilities for expanding Prototek’s capabilities in other areas of additive manufacturing. Prototek has already begun testing the system with new product lines, aiming to explore its utility across a broader range of materials and parts.

With PostProcess Technologies as a partner, Prototek is positioned to continue improving its operations by implementing advanced post-processing solutions tailored to meet the demands of high-volume production. The two companies are working together to identify opportunities for further automation and efficiency gains, potentially integrating additional PostProcess systems as Prototek’s needs evolve.

Conclusion

Prototek’s adoption of PostProcess Technologies’ DEMI 910™ represents a transformative step in resin post-processing for additive manufacturing. By addressing the limitations of traditional methods, the DEMI 910™ provides Prototek with a scalable, efficient, and environmentally friendly solution that supports consistent, high-quality production. This case study highlights the value of advanced automation in modern manufacturing, particularly in areas where precision and reliability are paramount.

As Prototek explores further applications for this technology, the DEMI 910™ stands as a testament to the power of innovation in driving operational excellence. With continued advancements in additive manufacturing and post-processing, companies like Prototek are well-equipped to meet the demands of today’s dynamic market while setting new standards for quality and sustainability in the industry.