Industrial manufacturing as a sector has been an early adopter of robotics and other forms of technological improvements for decades. Robotics have been one of the best options to increase production efficiency for large and often highly repetitive manufacturing processes. But the era of producing large quantities of just a few products with low mix is coming to an end, giving way to increased product personalization requiring a more flexible production process with less waste than ever before.

Industrial manufacturing as a sector has been an early adopter of robotics and other forms of technological improvements for decades. Robotics have been one of the best options to increase production efficiency for large and often highly repetitive manufacturing processes. But the era of producing large quantities of just a few products with low mix is coming to an end, giving way to increased product personalization requiring a more flexible production process with less waste than ever before.

Fortunately, the future of manufacturing is brimming with opportunity. It is full of new technologies designed to reduce waste and maximize process efficiency and flexibility through software and hardware capabilities. Almost all of this promise is built upon a foundation of digital transformation – and the digital twin. Everything from raw material tracking to process optimizations to hardware selection stems from insights gained from the digital twin and a closed-loop optimization of entire facilities.

The most difficult aspect of any change to operation are the inevitable changes to process, they are expensive twice over, because nothing is being produced and resources are still being consumed. An autonomous transport initiative squarely addresses this, relying on a few, key technologies to make it happen.

The Power of Virtual Commissioning

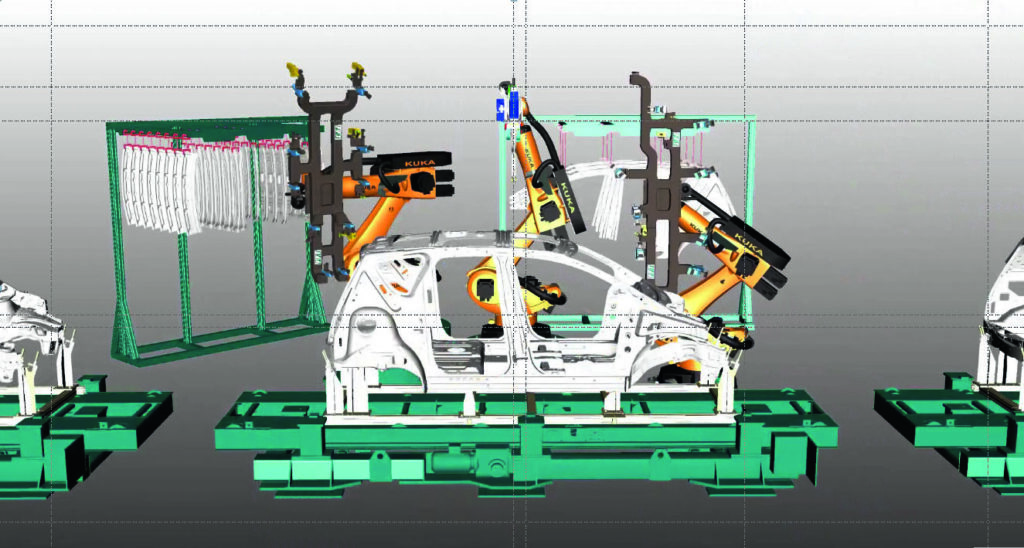

Creating a comprehensive digital twin of your production process can greatly reduce downtime for new machines, new processes and new products. Let’s say you need to install a new CNC station. What if the processes for this new machine could be validated before it ever arrived on the production floor by using the digital twin of the production line? Less time could be spent integrating the new component into the overall production lines through line integration as a part of virtual commissioning. Available today, virtual commissioning is the critical underpinning to an efficient production environment enabling a closed-loop iterative optimization of the entire facility.

Virtual commissioning is vital, not only for testing software controls, but for adding insight to the efficiency of the controls strategy. It is also essential for embarking on the advanced robotics journey, laying the groundwork for implementing greater process automation and flexibility needed to efficiently implement tomorrow’s manufacturing technologies today.

Simulate Everything Upfront

One of the best options to minimize risk when updating an existing process or making a new one is to simulate the new operations. It nearly eliminates upfront investment in machinery before knowing whether the new process will operate as expected on the shop floor. For new digitalization efforts, this is where a digital twin should be established for the process. Without a comprehensive study of the actions within a plant new equipment could be under-utilized leading to lost investment.

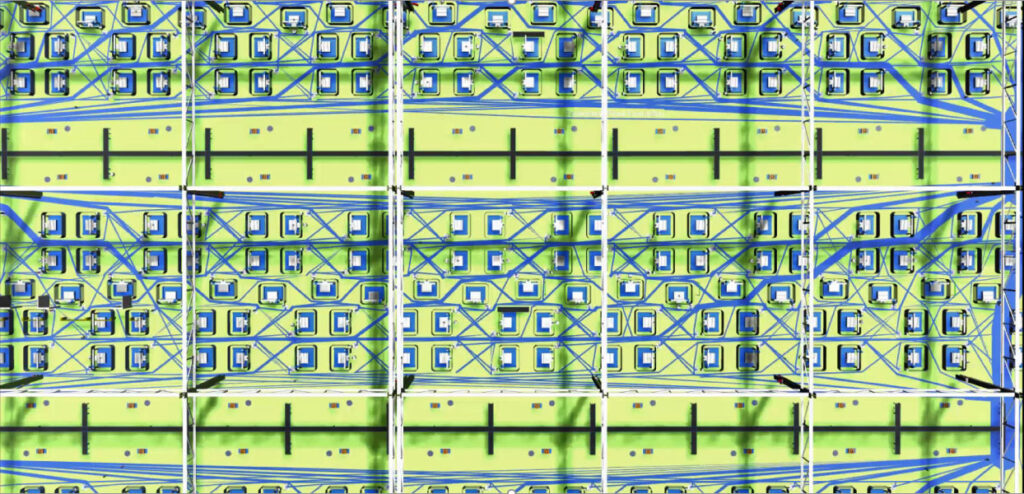

Just as important is the implementation of IoT devices, that serve to close the loop between the digital twin and the physical processes once the new processes have been initiated. Although these devices are often embedded in new production equipment, but it is important to consider how to best maximize the voluminous data they generate to gain crucial insight into the production process.

Next Generation Programming

Another route to maximizing production time even when supporting a high product mix is to expedite the reprogramming of the robotics in use on the factory floor. Without integrated robotic control, updating a robotic arm for a new task can be incredibly time-consuming. It needs to be taken offline, reprogrammed, validated and restarted, for each robot that will handle the new processes.

All that changes by integrating the programmable logic controllers for these robots into the comprehensive digital twin. Much of this process can be streamlined. Does a bolt spacing on a phone need to be shifted slightly to accommodate the latest 5G wireless antenna? If the entire fleet of robots working on that production line could understand the change, that would save many hours across multiple engineering and production teams. Engineers simply need to let the robots know of the change and any differences in manufacturing tolerances can be accounted for with closed loop sensing through visual or force feedback. With force feedback within the robotic arm, any force exerted over a defined threshold can initiate a pause to the robotic arm’s actions and readjust positioning to address the perceived problem. Instead of shutting them down for reprogramming, all the robots working on the project can adjust independently to subtle changes.

Although this might sound like some futuristic scenario, task-based programming has already been tested in the real world. In a partnership between AtriMinds and B/S/H/, Siemens Digital Industries Software helped bring flexibility to robotic arms by enabling automation for flexible products. Previously, one of the largest hurdles to automating assembly was how to work with flexible components. Traditional robotics rigidly follow predefined movements, so if something were to inadvertently shift, the whole assembly could be destroyed. But by implementing force sensing on the robotic arms, there is an almost intuitive understanding of the parts and how the robot is interacting with the workpiece at its station. If a hole is slightly out of place on a panel, the input from force sensors can help the robot redirect its movement and thread a screw through without complex, preprogrammed instructions for misalignment scenarios.

Optimizing Production with Autonomous Robotics

Simulation, virtual commissioning and advanced robotics programming lay the foundation for a fully flexible production floor, but automated guided vehicles (AGVs) and autonomous mobile robots (AMRs) weave it all together and bring it to life. Historically, conveyor belts acted as the material flow paths on a shop floor. They efficiently move product from point A to point B but require semi-static positioning. Even mobile conveyor systems, common in logistics work, take time to move and to ensure a safe path for product.

In contrast, AGVs and AMRs can change their path during transit. This saves time that would have been spent readjusting existing features, this is critical for a flexible production environment. Imagine a production floor, making two distinct version of a product. For version one, the bolts need to be added before the secondary assembly is added, while in version two bolts cannot be added until after the sub-assembly has been mounted. In a static conveyor facility, this could be completed given enough conveyor length and a sorting mechanism. Beyond a couple variations to the production sequence the factory would fill up with conveyor loops that only transport a few products at a time, defeating one of the main goals of the technology But with a fleet of AGVs or AMRs moving materials and work pieces throughout the facility, products can be rerouted and the sequence reordered to another machine. Or, in the case of highly customized consumer products, components could be routed to the best machine for the task. It can account for how much time is required to switch over to the new process, how many units can it produce compared to other machines, and even the impact of a re-route on other processes on the shop floor.

Reaping the Benefits of Tomorrow’s Robotics Today

Achieving all this requires a highly integrated production process. To guarantee a product is still made correctly during an automated process change, it needs to be simulated beforehand using a digital twin. To certify the product can be made in the new location, the production machine needs to be validated for the task using virtual commissioning. And to ensure the slightly different parts don’t produce errors in the process, the machines themselves need to be flexible to adapt to in real time to changing conditions with AGVs and AMRs.

Properly managing all these variables can have an incredibly positive effect on process performance, in fact it can produce up to a 40 percent improvement in labor productivity, according to a 2020 McKinsey study. Understanding the shop floor is an invaluable proposition and will continue to net savings and improvements through the life of the facility, even making it last longer by reducing maintenance overhead and costs with the improved condition monitoring of extensive IoT and the comprehensive digital twin.