Maximum safety and flexibility in shaping in terms of sophisticated neck geometries and wall thickness gradients for very high operating pressures are the key issues when it comes to the production of aluminum hydrogen tanks. Leifeld Metal Spinning GmbH is launching an innovative forming machine on the market that meets these requirements and helps to reduce CO2 emissions.

Manufacturers of hydrogen-powered vehicles have clear requirements for hydrogen tanks: absolute safety, maximum filling volume and maximum flexibility in the design of the tank shape. All three requirements are met by hydrogen tanks manufactured with the necking-in machine AFC from Leifeld Metal Spinning GmbH.

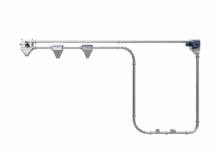

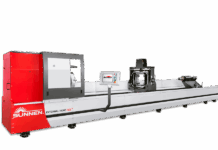

AFC stands for Aluminium Forming Center. The machine forms the ends of the aluminum cylinders for hydrogen storage using a special necking-in process. As hydrogen tanks underlie high operating pressures in their application, the entire neck area is optimized in its wall thickness profile during the forming process for long-term durability. In addition to the standard necking-in machine, the German machine manufacturer also offers a machine type that combines the necking-in and flow forming technology to form both, the entire pressure vessel body and the necks.

Customers can choose between two equipment options for preheating the material: gas burner or induction system. Once the pipe ends have been heated, the material is necked in. The process is completed by controlled loading and unloading as well as automated programming. “With our necking-in machine LEIFELD AFC, we are setting new standards in the forming technology for hydrogen tanks. Maximum safety, increased flexibility and a contribution to CO2 reduction combined with the famous LEIFELD technology promise – these are the innovations the automotive industry needs,” says Oliver Reimann, CEO of Leifeld Metal Spinning GmbH.

Safety ensured through intact surface

Hydrogen tanks operate under immense pressure. Scratches or other defects on the surface would be catastrophic. To prevent damage to the material, the R&D team, led by Benedikt Nillies, Technical Director at Leifeld, has come up with several solutions. For example, the heating of tube ends in the machine: “Normally, the tube ends are heated by a gas oven or an induction system outside the machine,” says Benedikt Nillies. However, during subsequent loading, the component cools down. “We want to prevent this,” Nillies continues. “With the AFC machine, the tube ends are either heated by an integrated heating device with a gas burner or electrical induction to processing temperature uniformly. We can precisely adjust the temperatures to the desired level. This avoids coarse grain formation and preserves the material’s strength.” Valid forming tests for aluminum tanks confirm the success of this innovation.

To keep the surface intact, Leifeld offers various spinning rollers – from simple necking-in rollers to actively driven forming rollers. The rollers, developed and manufactured by Leifeld, rotate upon contact with the part, preventing surface defects by avoiding material buildup on the roll. The support device was specially designed so that it can absorb the forming forces even with very thin wall thicknesses. The cylinder is held stably in a precise position, ensuring tight tolerances and surface accuracy even at high forming forces and forming speeds. The innovative support system can be used for parts up to 6 meters in length.

Even stepped tanks can be manufactured for use in cars

There are no limits to the design of aluminum cylinders. Thanks to the flow-forming and necking-in technology, even stepped dimensions can be realized. “Some of today’s hydrogen tanks have to be integrated into existing vehicle architectures with limited installation space. For example, a tank could be stepped in such a way that it takes up as little space as possible and has the maximum filling volume. With this innovation, we aim to contribute to electromobility with hydrogen,” says Benedikt Nillies.

Use of hydrogen tanks interesting for other sectors in the future

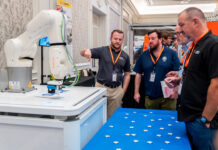

Hydrogen tanks are currently primarily used in cars, trucks and buses. However, Benedikt Nillies also sees the possibility of using hydrogen tanks manufactured on LEIFELD machines to power rail vehicles and aircraft as feasible: ” We are continuously developing the process and have received initial inquiries from other industries. Additionally, we are currently working on automating loading and unloading systems in order to adapt the machine even more efficiently to the customer’s material flow.”

Leifeld Metal Spinning GmbH emphasizes its clear focus on innovation and progress, as well as quality leadership as a solution provider, deeply rooted in the corporate culture. The company has its own application center in Germany and Japan, along with in-house research and development capabilities, driving the continuous development of new technologies.

About Leifeld Metal Spinning

Leifeld Metal Spinning GmbH develops, manufactures, and distributes machine tools for chipless metal forming. More than 200 employees work at locations in Germany, the USA, Japan and China. The company is member of the Global Metal Forming Group and is present worldwide with numerous representatives in all major markets. The core industries are automotive, aerospace, energy, and industrial applications. The production site and headquarters are located in Ahlen, Germany.

The product range includes machine tools for the manufacture of various intermediate or end products. The machines are equipped with multifaceted automation solutions and can be individually adapted to suit the customer’s requirements. In 130 years of business, Leifeld Metal Spinning has manufactured over 6,150 machines and delivered them to 60 countries.

Leifeld Metal Spinning also supports its customers with a comprehensive range of services which cover the entire product lifecycle. The company offers all the services – ranging from research & development, technical service, spare parts procurement, consulting, and training to the retrofitting of second-hand machines. Leifeld develops new processes, technologies, and products, and has filed for patents on more than 140 inventions to date.