Though Jonathan Egan spent his youth working around cars, today boats dominate his time. Egan runs the fabrication shop at Lyman-Morse, a company born in 1978 on a site along the coast of Maine where wooden schooners have been built for more than 200 years. Lyman-Morse operates two boatyard’s now and a modern metal fabrication shop, which is Egan’s domain.

Though Jonathan Egan spent his youth working around cars, today boats dominate his time. Egan runs the fabrication shop at Lyman-Morse, a company born in 1978 on a site along the coast of Maine where wooden schooners have been built for more than 200 years. Lyman-Morse operates two boatyard’s now and a modern metal fabrication shop, which is Egan’s domain.

A Lifetime of Boat Building

Between the two boatyards and fab shop, there are projects at all stages of construction and repair. A variety of custom and semi-custom sailing and motor yachts, new builds, refits, upgrades, and restorations. A Lyman-Morse built boat can reach 130 feet in length, move with the use of a sail or engines, and cost from tens of thousands to many millions of dollars.

Approximately 100 full-time craftsmen work at Lyman-Morse. Many have made a lifetime career of fine boat building. Some are even third, fourth, and fifth generation shipwrights and custom boat builders. These craftsmen are skilled at working with a multitude of natural and man-made materials: wood, bronze, brass, copper, titanium, steel, stainless, aluminum, iron, fiberglass, and composite.

In the case of a boat, materials need to provide strength and rigidity, while remaining light, responsive to steering, and mindful of fuel consumption. Modern technologies and methods are incorporated throughout the process, while in-house designs are tempered with traditional and Downeast designs. This is Maine after all.

Perhaps, not surprisingly, the company’s busiest months are in late winter and early spring as boat owners focus on getting their boats ready for the warmer weather that’s on the horizon. It is during this time that Lyman-Morse’s boat builders work 12-hour days, seven days a week.

While still busy during the remainder of the year, Lyman-Morse does have a little more leeway to take on other projects which it happily does because as Egan says, “If you can build a boat, everything else seems simple. A boat is basically a house on water. It has plumbing, electrical work, fine cabinetry, mechanical aspects, and so on.”

Projects Large and Small

Projects Large and Small

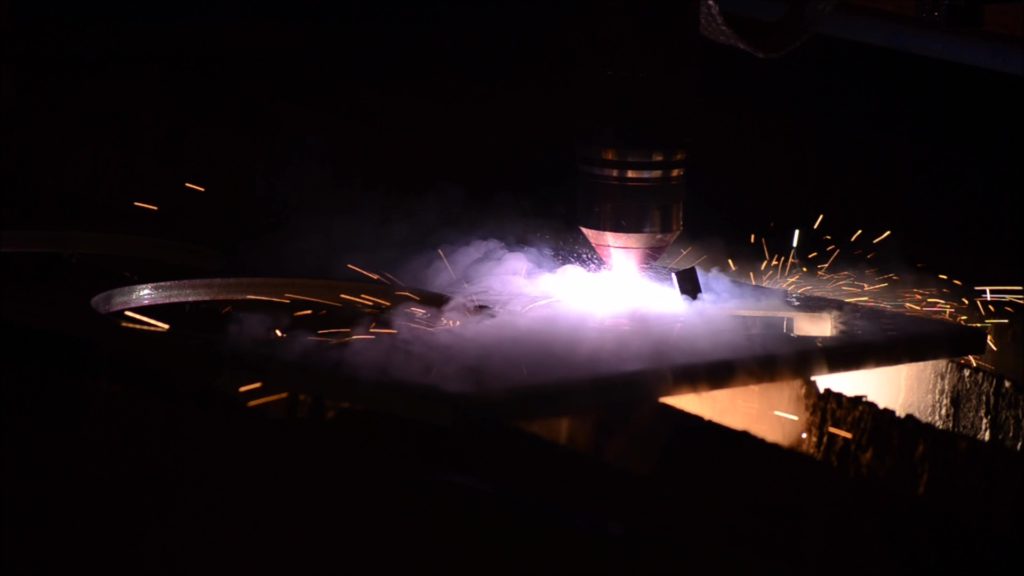

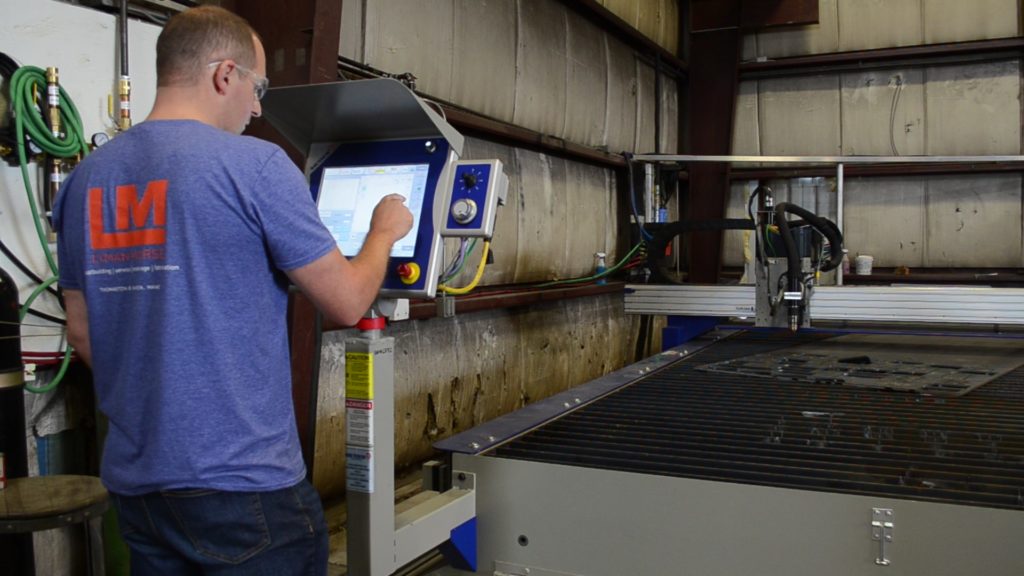

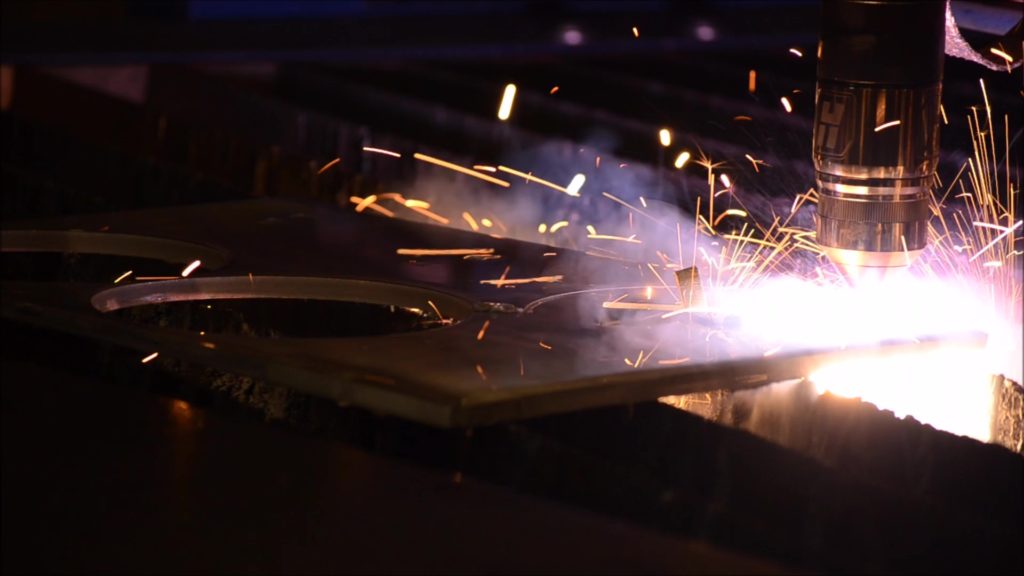

At 15,000 square feet, Lyman-Morse Fabrication’s shop contains a wide range of equipment necessary to complete the varied projects the company may take on. That equipment includes benders, a CNC vertical machining center, presses, shears, large and small lathes, milling machines, large band saws, and a 5-ton bridge crane to help move pieces into place. Also in the shop is the company’s newest acquisition: an XPR300 with X-Definition Plasma from Hypertherm.

“The XPR300 cuts everything for all three Lyman-Morse locations, plus general contractors and the public. We’ll do anything, from fixing a lawnmower blade to a newly fabricated spiral staircase, or even a five-story hotel,” Egan says. “We keep a full stock of metals on-hand so we can react quickly. Sometimes we’re given plans, but we do have three design engineers on staff who can draw anything using SolidWorks a CAD software.”

The company has made conveyers, tanks, solar mounting kits, aluminum window cladding, architectural projects, structural steel buildings, and ornamental ironwork like stairs and railings, fences, gates, and signs, among other things in a fairly wide range of thicknesses, from 18 gauge on the thinner end of the spectrum to more than 2”. The XPR300, selected with Hypertherm’s OptiMix gas console option, is on a system designed and built by Messer Cutting Systems. The Messer MetalMaster Evolution gantry is attached to a cutting table Messer calls The Slagger.

The company has made conveyers, tanks, solar mounting kits, aluminum window cladding, architectural projects, structural steel buildings, and ornamental ironwork like stairs and railings, fences, gates, and signs, among other things in a fairly wide range of thicknesses, from 18 gauge on the thinner end of the spectrum to more than 2”. The XPR300, selected with Hypertherm’s OptiMix gas console option, is on a system designed and built by Messer Cutting Systems. The Messer MetalMaster Evolution gantry is attached to a cutting table Messer calls The Slagger.

This design, in which the gantry is attached to the table rather than the floor, really appealed to Egan as the Lyman-Morse Fabrication shop contains radiant heating. While offering numerous benefits, the radiant heating system meant Lyman-Morse could not bolt the table gantry to the floor as is often done. Egan was also impressed by the Slagger’s auto cleaning feature. The system is designed to push slag from the bottom of the bed to the end of the table and into a pan for easy disposal.

“I wanted the XPR from the start, but I was looking at different table manufacturers,” Egan begins. “Messer had the nicest unitized machine with the gantry connected to the table … This way, if we move the machine, the gantry goes with it and tolerances are tighter. I also didn’t want the control monitor attached to the gantry and have the operator move along with it. That was a safety concern for me.”

Messer’s Project Manager, Jim Naczek, worked with Egan, “Jonathan flew out to Wisconsin to perform process capability testing on an actual system at our headquarters. He had serious equipment demands for stainless cutting and he was pleased to see that the system could do what he needed it to do.” Naczek explained, “With the MetalMaster Evolution we’ve brought together two of our most productive designs, the EdgeMax and MetalMaster Plus, and added innovations in bevel cutting, beam design, and unitization.”

Messer’s Project Manager, Jim Naczek, worked with Egan, “Jonathan flew out to Wisconsin to perform process capability testing on an actual system at our headquarters. He had serious equipment demands for stainless cutting and he was pleased to see that the system could do what he needed it to do.” Naczek explained, “With the MetalMaster Evolution we’ve brought together two of our most productive designs, the EdgeMax and MetalMaster Plus, and added innovations in bevel cutting, beam design, and unitization.”

Getting Past a Myth

Though Egan is very happy with his purchase, he admits a new plasma system wasn’t always his first choice. “I needed to get past the waterjet myth first. I thought that I could only use waterjet because of the heat affected zone. Salt water corrosion on stainless steel is nasty and a real concern for me,” he explains. “I don’t want to disappoint our customers after they have invested so much, but through my research, I realized that plasma has come a long way. The heat affected zone is so minuscule, like .001”, and can be easily knocked-off with a grinder, plus we mirror polish the metal anyway.

“We can cut fast with the plasma and do things that we couldn’t do with the waterjet. Waterjet is just so slow and requires more maintenance. The XPR300 is a wonderful machine. Cutting with a water process was the biggest selling point for me. We get such clean cuts on stainless and aluminum that I don’t even need a waterjet. The edge quality is amazing.”

The XPR300 selected by Lyman-Morse utilizes a new class of plasma, which Hypertherm calls X-Definition Plasma. When paired with the right cutting system like the one from Messer, the system is capable of maintaining ISO 9013 Class 1 and 2 tolerances and ISO 9013 Range 2 and 3 cut quality. Further, the system can deliver edge surface finish that is generally smoother than fiber laser in the thicker ranges and extremely consistent edge quality over the full life of a consumable set.

The XPR300 selected by Lyman-Morse utilizes a new class of plasma, which Hypertherm calls X-Definition Plasma. When paired with the right cutting system like the one from Messer, the system is capable of maintaining ISO 9013 Class 1 and 2 tolerances and ISO 9013 Range 2 and 3 cut quality. Further, the system can deliver edge surface finish that is generally smoother than fiber laser in the thicker ranges and extremely consistent edge quality over the full life of a consumable set.

Lyman-Morse’s new plasma also includes SureCut technology giving the company access to Hypertherm’s True Hole process, which it uses on mild steel. In addition, the company utilizes the XPR300’s marking capabilities to note bend and weld lines for its metal workers.

Lyman-Morse Fabrication is confident this new cutting table will afford it much greater control of project timelines and undoubtedly open the door to a wider marketplace as the first fabricator in Maine with X-Definition cutting technology.

About Hypertherm

In 1968, Hypertherm founder Dick Couch and colleague Bob Dean discovered a way to create a narrower plasma arc, capable of cutting metal more quickly and more accurately than ever before. Nearly 50 years later, the founding principle of customer-focused innovation continues to drive product development at Hypertherm. Hypertherm is committed to engineering and building the best industrial cutting solutions on the market. From humble beginnings in a two-car garage to becoming a world-class manufacturer of advanced cutting solutions, their story has been one of innovation, hard work, and customer focus.