What happens when your company outgrows not one, but two production facilities in just two decades? You build one of the largest manufacturing facilities under one roof in all of Ireland. Combilift, an Irish forklift and material handling products manufacturer, has developed into a powerhouse for lifting and loading solutions. In May, Industrial Machinery Digest was given the opportunity to tour the new facility during its official opening.

A Growing Business

There is a lot to be said about a business that cares about where it plants its roots. Since 1998, Combilift has been focused on meeting their clients’ needs with their customized products. Going up against established forklift brands like Toyota and Mitsubishi, Combilift focused on manufacturing forklifts for niche markets. The first market they cornered was long-load handling, such as timber or steel. This was Combilift’s focus for the first ten years.

There is a lot to be said about a business that cares about where it plants its roots. Since 1998, Combilift has been focused on meeting their clients’ needs with their customized products. Going up against established forklift brands like Toyota and Mitsubishi, Combilift focused on manufacturing forklifts for niche markets. The first market they cornered was long-load handling, such as timber or steel. This was Combilift’s focus for the first ten years.

“Combilift is an incredible home-grown Monaghan success story,” said Irish Prime Minister An Taoiseach Leo Varadkar TD. “When the company was founded 20 years ago, it had three employees, a brilliant concept, and the ambition to make it a reality. Combilift is playing a significant role in Monaghan’s success.”

The new global headquarters cost €50 million, or just below $59 million dollars to build. The 500,000 square foot manufacturing facility will allow Combilift to double their production. Currently, Combilift employees 550 employees but will be adding an additional 200 skilled technicians, design engineers, logistics and supply chain specialists and those with mechanical and electrical mechatronics skills to their ranks.

The New Factory

The new factory sits on 100 acres with room to grow. The four 90 meter moving assembly lines produce a new truck every fifteen minutes. The facility focuses not only on producing the best material handling solutions, but also on sustainability.

Thirty percent of the roof space features natural skylights allowing the workforce to work under natural lighting through much of the facility. Combilift is also taking advantage of solar technology. Solar panels supply 185 kilowatts of energy to the facility. A biomass plant is fueled by recycled wood heats the spraying booths and assembly area. Furthermore, 110,000 liters of rainwater is harvested for jet washing and bathroom facilities.

Thirty percent of the roof space features natural skylights allowing the workforce to work under natural lighting through much of the facility. Combilift is also taking advantage of solar technology. Solar panels supply 185 kilowatts of energy to the facility. A biomass plant is fueled by recycled wood heats the spraying booths and assembly area. Furthermore, 110,000 liters of rainwater is harvested for jet washing and bathroom facilities.

The factory includes 60 welding bays, two plasma cutting machines, three paint lines utilizing sustainable water-based paints, and three automatic shot blasters to cater different sized products.

Combilift has also included a dedicated R&D Development and Testing center.

“We work closely with our customers and dealers to identify solutions that best match their individual specific needs,” says McVicar. “Combilift invests 7% of its annual turnover (revenue) in Research and Development (R & D) to enhance its customization capability. We are intensifying the collaboration with our customers in the warehouse and material handling sectors. The intention is to maximize return on revenue (ROI).”

New Frontiers

Combilift developed the world’s first multidirectional all-wheel drive IC engine powered forklift. Their first year, the company produced 18 units, all but one were exported. In the last five years, Combilift now has 40,000 units in operation in more than 85 countries across the globe. Within the last decade, the product range has been further diversified by the development of more innovative space saving warehouse and heavy load handling products such as their Aisle Master articulated truck and the Straddle Carrier (Combi-SC).

“Mass customization is the new frontier for both the customer and the manufacturer. Increasingly customers are expecting products to be tailored to meet their needs,” explains Martin McVicar, managing director for Combilift. “Forklift producers that offer customized products generally produce low volume, but Combilift is setting the benchmark by offering the mass production of tailored products, resulting in a strategic advantage for our customers. Traditional forklift manufacturers focus on high volume mass production of the same products. We evolve with our clients, producing new products each year.”

And now, in 2018 their new facility allows for that ever constant evolution to continue. As materials continue to grow larger, safer material handling methods that ensure the protection of workers is an increasing demand. Launched during the grand opening, Combilift has released a new high capacity powered pallet truck that offers safer operation, maximum operator visibility and narrow aisle performance, the Combi – PPT.

“It is Combilift’s intention to significantly expand its pedestrian forklift range as can be seen with the launch of this high lift capacity Combilift Powered Pallet Truck (Combi-PPT)” says McVicar.

With a lift capacities of 3,000 kilograms and 6,000 kilograms, and models with even 7,000 to 16,000 kilograms available on requests, the Combi-PPT allows the operator to stand-on or walk behind during operation. Standard features include power steering, AC motor technology, and the rear wheel drive Combi-PPT features Combilift’s patented multi-position tiller arm. Combilift offers optional extra’s such as wider and longer forks, mounted camera, and fork configurations for reels, among others.

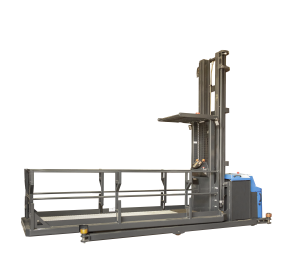

The Combi-OP Order Picker

Combilift’s purpose built order picker, the Combi-OP delivers standing operator over-head guard and multi-function steering/function control that meets the demands of long product material handling. Previously, operators had to manage long product by modifying traditional order pickers. The Combi-OP gives a non-compromised operation for easy picking of long profiles in, for example, steel service centers.

Combilift’s purpose built order picker, the Combi-OP delivers standing operator over-head guard and multi-function steering/function control that meets the demands of long product material handling. Previously, operators had to manage long product by modifying traditional order pickers. The Combi-OP gives a non-compromised operation for easy picking of long profiles in, for example, steel service centers.

Also debuting at the grand opening, the Combi-OP operates in narrow aisles with a capacity of 450 kilograms. Operators can easily and safely hand pick orders for customers from the roomy elevated platform featuring a light anti-slip floor, self-closing platform gate and guard rails guaranteeing the utmost safety. Safety is also ensured during travel as the steering angle automatically adjusts according to lift heights.

Focusing on Tight Spaces

In 2008, Combilift decided to focus on other markets that were not as reliant on the construction industry that deals primarily with long product. With the development of their Aisle Master line, Combilift set their sights on providing a superior product for the warehouse and storage and distribution industry. Space utilization in a warehouse is always at a premium. The Aisle Master allows for operation in as little as 72 inches.

Warehouse and storage facilities dealing with palletized goods typically have two options when they outgrow their current facility. The options are either expand your current facility or move to a new one. Combilift gives you an important third option. By designing aisles to take advantage of the tight operating space that Combilift’s Aisle Master can operate in, one can further utilize the space they already have.

Warehouse and storage facilities dealing with palletized goods typically have two options when they outgrow their current facility. The options are either expand your current facility or move to a new one. Combilift gives you an important third option. By designing aisles to take advantage of the tight operating space that Combilift’s Aisle Master can operate in, one can further utilize the space they already have.

With the Aisle master, an operator is able to steer the forks to turn sideways on either right or left, with good visibility, and pick up pallets or whatever the materials might be. The cabin is ergonomic friendly ensuring driver satisfaction and can be had in either electric or LPG (Liquid Petroleum Gas) powered units, depending on customer preference. With reduced driver fatigue, the Aisle Master provides faster load-cycle times and unbeatable maneuverability.

Optimizing Shipping Solutions

For a company that has had much success with exporting their product, Combilift knows the advantages of making a product easy to ship within a transport container. With the Slip Sheet system, Combilift has engineered a solution to load a transport container faster, safer, and more efficiently.

Designed similar to a conveyor belt, the Combi-CSS (Container Slip Sheet) manages heavy, long loads to be slid securely into a container or loading truck. Once the product is fully inserted, the gate enclosure closes, securing the product in place, and the sheet is pulled out. This innovative design allows for easier shipping of pipe, wind turbines, or other long materials that are typically difficult to transport and would normally require use of a crane.

Meeting Customers’ Needs

Combilift solutions have always taken into account the customer’s needs. Frequently, their designs come from direct input from their clients. At the Grand opening, the first Combilift  unit produced in 1998 was on display. Today, twenty years later, this unit is still in operation. While the reliability of a Combilift product is clear, this is not the largest asset the company has after twenty years. Combilift has managed to remain flexible as it has grown into its new global headquarters.

unit produced in 1998 was on display. Today, twenty years later, this unit is still in operation. While the reliability of a Combilift product is clear, this is not the largest asset the company has after twenty years. Combilift has managed to remain flexible as it has grown into its new global headquarters.

“The flexibility in our new facility means that Combilift can continue to accommodate any customer request for a customized material handling solution,” says McVicar “The new factory enables us to double production and remain focused on the needs of our customers and dealers. We have become much more than a forklift manufacturer and are transforming the transport and logistics sector with our innovative, space-spacing products.”