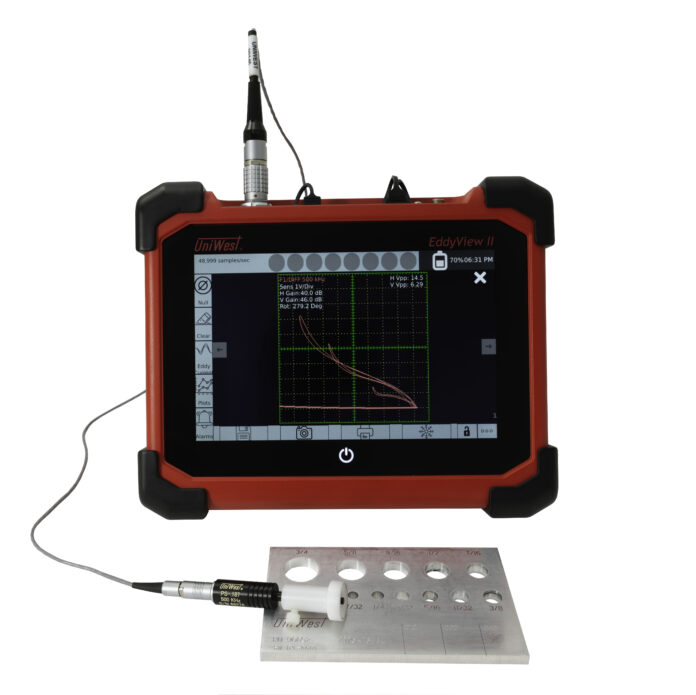

UniWest announced the introduction of the new EddyView® II portable eddy current flaw detector at the ASNT Annual 2022 Conference on October 31, 2022.

The innovative EddyView II features a large 8-inch touch screen display with gesture adjustments for key parameters such as gain and rotation, ability to drive conventional probes or array probes, an independent channel that monitors probe to part coupling (liftoff), and UniWest’s industry-leading signal performance with extremely low signal-to-noise.

The EddyView II also includes multi-frequency probe drive and signal mixing, digital conductivity & non-conductive coating thickness, and compatibility with UniWest’s ECS-1S & JF-15 rotating bolt hole scanners. In addition, the EddyView II can be connected to the internet for remote diagnostics and calibration, as well as export raw eddy current data for post-processing flexibility.

While using the EddyView II in demanding and often dirty NDT environments, its rugged housing is designed to meet the standards of Ingress Protection (IP) rating IP-65.

Kurt Oldson, UniWest’s President, stated: “The EddyView II has been designed with customer feedback in mind, featuring new and innovative technological advancements, but one primary request kept standing out: Don’t lose the low-noise signal path that has helped define UniWest products. We took that customer input very seriously, and our engineering team delivered!”

Designed for use by NDT professionals, the EddyView II includes all the advanced features and functionality to allow both standard eddy current measurements and complex inspections, including use of eddy current array (ECA) probes up to 32 elements as well as large-scale automated and robotic production applications. System features include multi-frequency with mixing, split-screen for both impedance plane and O-scope/sweep modes, digital conductivity measurement, non-conductive liftoff digital measurement, rotating scanner support for high-speed bolt hole scanning, Ethernet connectivity, alarm outputs, and USB flash drive support. Ideal for field, laboratory, or production settings, the EddyView II’s fast data acquisition rate facilitates smooth system integration.

About UniWest

United Western Technologies Corp, (DBA UniWest) is a worldwide leader in the Non-Destructive Testing (NDT) industry. We design, manufacture and service NDT instrumentation and sensors with pride in quality workmanship. Our products can be found in the field, testing jet engine components; in the laboratory, analyzing new & unusual materials; and on the production line, using multi-coil arrays. UniWest will tailor a complete turnkey sensor & NDT system for your inspection needs. Our goal is to provide a practical and robust solution to your application.

UniWest serves the following industries: Aerospace, Power Generation, Primary Metals, Manufacturing and Automotive.

In 1985, UniWest was founded with four employees and one contract. Among our core beliefs is that all clients are treated fairly, with a relationship akin to a doctor and their patient. We want them to know that we believe in confidentiality and in our ability to understand their problems and to solve them. This philosophy of trust and honesty, combined with engineering competence, ensures loyal customers. At UniWest every employee is dedicated to providing customer satisfaction; a goal that our customers expect and deserve. UniWest is proud to be 100% employee owned, and as a result, our employees are committed to teamwork. www.uniwest.com