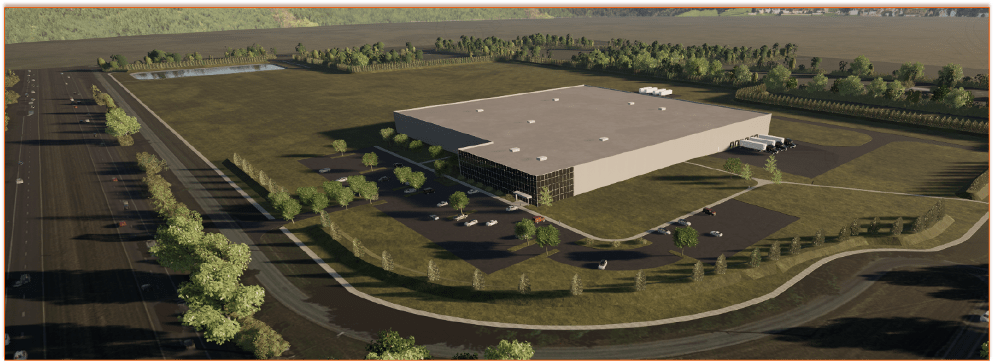

Toyota Material Handling has announced a nearly $100 million expansion project at its North American headquarters. This significant investment aims to enhance the company’s production capabilities and support its long-term growth strategy. The expansion will include the addition of new manufacturing facilities and the implementation of advanced production technologies. This project reflects Toyota Material Handling’s commitment to innovation and its dedication to meeting the growing demand for material handling solutions.

Advanced Automation Systems

The expanded headquarters will enable Toyota to better serve its customers and continue its leadership in the industry. One of the key components of the expansion is the incorporation of advanced automation systems. These systems are designed to improve production efficiency, reduce operational costs, and enhance the quality of the company’s material handling equipment. By integrating cutting-edge technologies, such as robotics and IoT, Toyota aims to create a more agile and responsive manufacturing environment.

Sustainability Initiatives

In addition to technological advancements, the expansion project emphasizes sustainability. Toyota is investing in renewable energy sources, energy-efficient building designs, and sustainable manufacturing practices to reduce its environmental footprint. The new facilities will feature solar panels, energy-efficient lighting, and advanced HVAC systems to minimize energy consumption. These initiatives align with Toyota’s global commitment to sustainability and environmental stewardship.

Economic and Employment Impact

The expansion project is also expected to create hundreds of new jobs, contributing to the local economy and supporting the growth of the manufacturing sector. Toyota is committed to fostering a diverse and inclusive workforce, providing employees with opportunities for career development and advancement. The company’s investment in training and education programs will ensure that its workforce is equipped with the skills needed to thrive in a technologically advanced manufacturing environment.