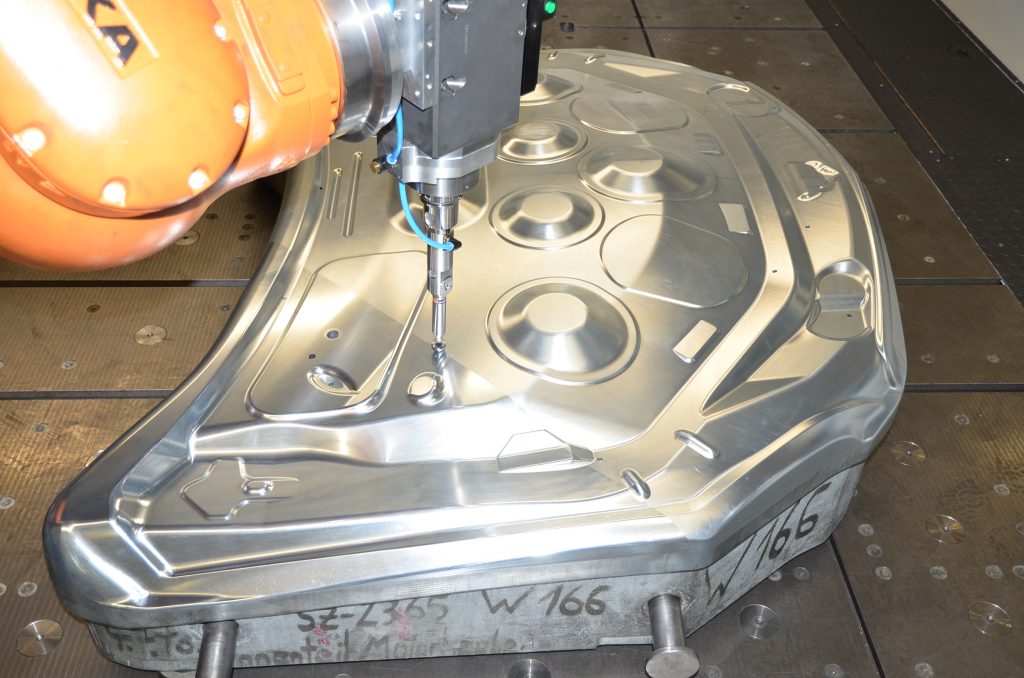

Polishing die tools is a required practice in the automotive industry to reduce surface roughness, prevent wear, and prolong service life. Automakers, like global powerhouse Daimler, commonly use a manual technique called hammer peening, in which a worker polishes the die by repeatedly striking the surface of the metal with a hammer. Manufacturers like it because it improves polishing speed, consistency, surface quality, and surface hardness by up to 30 percent while increasing the service life of the dies.

Unfortunately, the process has several shortcomings. It is labor-intensive, time-consuming, and the result is often inconsistent owing to differences in technique among operators. There are even differences when the work is done by the same person as each person’s level of fatigue varies throughout the course of a day. Subsequently, this impacts the consistency and quality of the stamped car body components and how they mount to the vehicle frame. This is an issue for any automaker, but the stakes are even higher when you are manufacturing the luxury vehicles Daimler’s Mercedes-Benz business is known for. Components with exemplary finish and fit are a necessity.

Robotic Hammer Peening for Speed, Consistency, Flexibility

Robotic Hammer Peening for Speed, Consistency, Flexibility

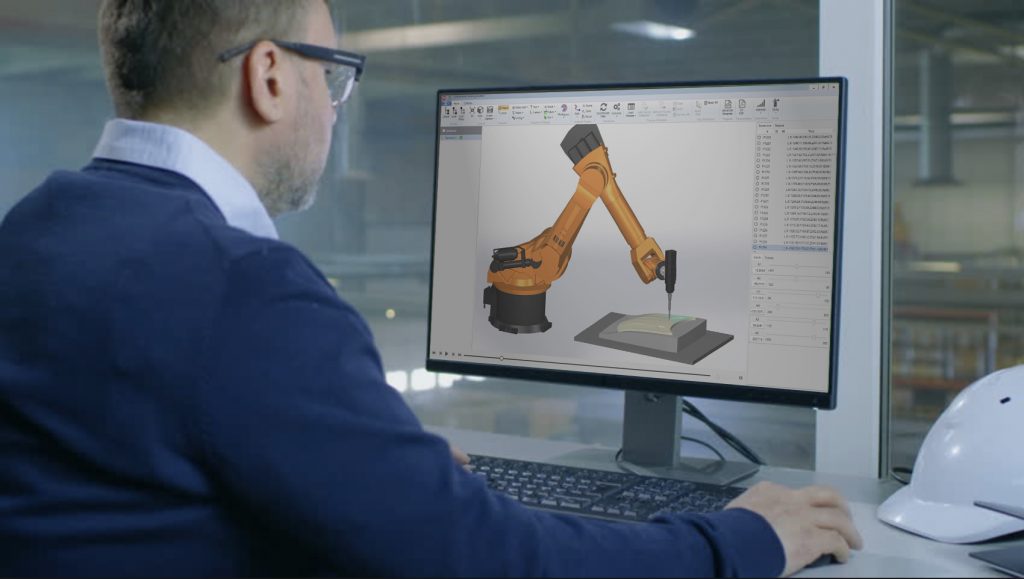

It probably comes as no surprise then that managers and leaders were constantly evaluating the current manual peening process and on the lookout for a way to improve it. They understood that doing so would save the company money and result in a better product. Their solution involved robots.

The Mercedes-Benz Ph.D. who spearheaded the development of the hammer peening process knows firsthand the advantages of robots. He says robots are less expensive than dedicated CNC machines and provide greater reach on large workpieces, in this case, dies weighing up to 25 tons and more than 16 feet (5 meters) in length. In addition, he likes that robots are more flexible and can work in many different applications.

To maximize their equipment investment, Daimler eventually planned to leverage robotics’ renowned flexibility for processes beyond hammer peening. However, engineers would first have to figure out how to automate the current process, something that proved a formidable challenge.

Developing the Right Robot Programming Solution

The hammer peening process used by Daimler specified the repeated striking of the die with a high-frequency impact spherical hammering tool. It required millions of impact points by the hammerhead to ensure homogeneous surface quality. To program a robot to manipulate the hammer peening tool with such frequency and precision was a monumental challenge, especially when using conventional software tools.

Even when using two to three different software platforms for code generation, calculating toolpaths, and converting to robot motion, Daimler’s existing programming tools were unable to handle all of the computations required to program a six-axis robot for hammer peening. Though the team had some success, it struggled to complete all of the programming. At a loss, Daimler approached the team responsible for Hypertherm’s Robotmaster software.

Daimler and the Robotmaster team embarked on an extensive, three-year R&D project to enhance and refine the robotic hammer peening process. The Robotmaster team worked closely with Daimler, collaborating on custom toolpath creation and ongoing development of the Robotmaster software to improve programming time and ease of use.

Daimler says they could not have developed this hammer peening process or the other robotic processes that would soon follow without the dedication of Robotmaster’s team. Robotmaster spent months working with the automaker, ensuring they understood what Daimler wanted and adapting the software for their specific applications.

Robot Programming Time Cut by 70 Percent

Robot Programming Time Cut by 70 Percent

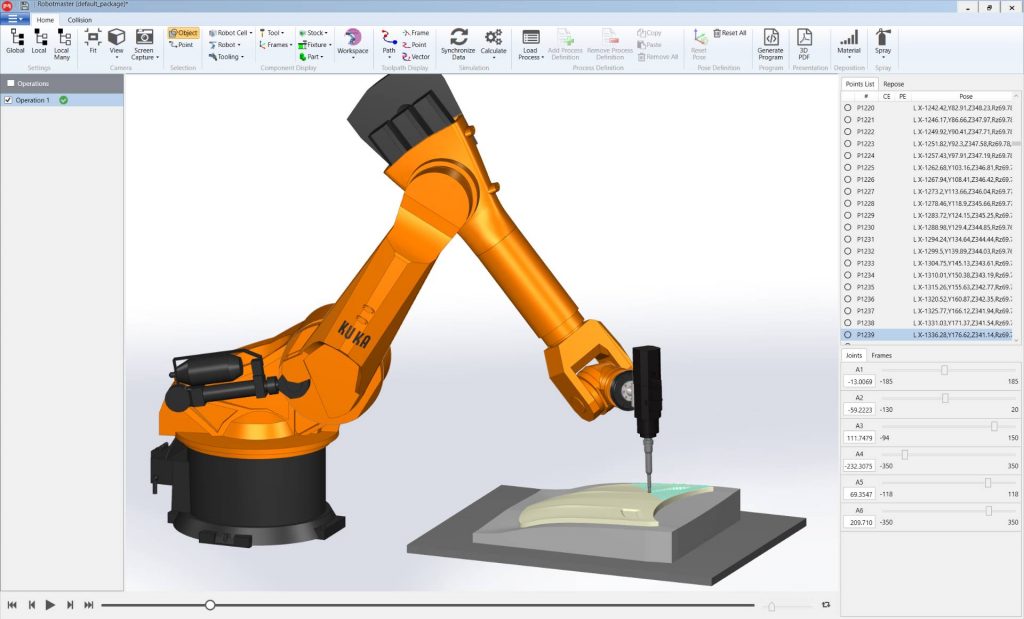

Robotmaster alone was able to do what no other software tool could accomplish, even in combination. The offline programming solution not only handled all of the calculations where others failed, but it also surpassed Daimler’s expectations by optimizing the entire robotic hammer peening process. The result was a 70 percent reduction in time spent programming, optimized robotic motion, smoother transitions, and the ability to program complex dies quickly and easily.

Total programming time for one workpiece, including the time to import a CAD file and create a toolpath, was reduced from 12 hours to 3.5 hours. Robotmaster’s kinematics solution accounted for only 45 minutes of that total programming time, a substantial improvement over previous attempts with other software platforms.

Pivotal to the Robotmaster solution was one of the fastest kinematics resolution engines available. It solves singularities, reach and joint limits, and any other sudden robot motion that can abruptly change the robot’s configuration or cause errors. The proprietary kinematics and collision detection engines check for errors, while the optimization tools smooth the robot motion. Transitions are clean. Unnecessary joint movements are minimized.

“Robotmaster has the best kinematics and collision detection engines on the market,” says Anbu Lingappan, European business development manager for Intercam SA, a distributor of Robotmaster software and part of the team that collaborated with Daimler on the hammer peening application. “When Daimler asked why it takes this long to process 3 million points, we had to explain how Robotmaster checks for kinematics issues at 150 iterations per point minimum for a six-axis robot. We do this in the background for each point in the path and at a very high speed. Only then do people realize that there are some serious calculations going on behind the scenes.”

The software also needed to control external axes with ease. Daimler’s hammer peening cell uses a KUKA KR 500 robot mounted on a rail to increase its reach, plus two rotary axes to position the workpiece. Robotmaster can manage up to 11 axes simultaneously, including a six-axis robot and five external axes. The simulation and optimization tools automatically support rails and rotaries as needed.

One Software Solution for Multiple Robotic Processes

Once Robotmaster proved themselves in the hammer peening application, Daimler began to explore using the software for other processes using a second, newly commissioned robotic cell. Unlike the first cell, this new cell had a multifunctional design. By simply changing out the end-of-arm tooling, the robot could embark on a variety of processes from laser hardening to drilling.

Daimler used Robotmaster software to program a robotic laser hardening process for their stamping dies. By laser hardening the fillets, they could gain 30 percent more service life from their die tools. Robotmaster was also used to program a robotic laser cladding process to build up worn surfaces of dies.

Today, Daimler is using Robotmaster software in three Mercedes-Benz die shops and in Daimler’s Digital Factory, where they build the core of their automobiles. Ultimately, Daimler was able to accomplish their goal to optimize and economize their processes by creating multifunctional robotic cells for hammer peening, laser hardening, laser cladding, milling, drilling, and induction hardening. All programmed with Robotmaster software.

Easy to Use, Everyone Benefits

Easy to Use, Everyone Benefits

Ease of use played a substantial role in Daimler’s adoption of Robotmaster software for offline programming. The Robotmaster Interactive Simulation Environment (RISE) is extremely powerful, providing an intuitive click-and-drag user interface for modifying the robot’s positions and trajectories.

Norbert Krach, managing director of robotized rm systems GmbH, Robotmaster’s local reseller in Germany, explains how Robotmaster’s user interface and proprietary technology provide unmatched control and flexibility.

“The user interface is unique. It’s impressive how easily you can get the toolpaths into Robotmaster and easily generate the code, simulate the process, and resolve any kinematics challenges,” says Krach. “With other software, you have to do a lot of trial and error. With Robotmaster, you resolve toolpaths easily and much faster. You don’t have to sit in front of a computer for hours tweaking points.”

Daimler continues to explore the use of robotics for different processes in the die shop and rely on Robotmaster to accommodate their robot programming needs. Intercam’s Lingappan says the automotive industry owes a debt to Daimler for their work in this field.

“We have to give credit to Daimler for helping us innovate the robotic hammer peening process. The rest of the market will benefit.”

About Hypertherm Inc.

In 1968, Hypertherm founder Dick Couch and colleague Bob Dean discovered a way to create a narrower plasma arc, capable of cutting metal more quickly and more accurately than ever before. Fifty years later, the founding principle of customer-focused innovation continues to drive product development at Hypertherm. And that spirit of innovation is one of the reasons why Hypertherm’s plasma, laser, and waterjet systems, software, motion controls and consumables consistently outperform the competition in cut quality, productivity, and cost-efficiency.

About Robotmaster

Robotmaster helps manufacturers to maximize their productivity by easy and efficient industrial robot programming. Our leading off-line programming software provides quick and easy programming tools for multiple applications, saving time and money while maximizing return on investment. The capabilities of Robotmaster have not gone unnoticed, winning praise and accolades from customers and media alike. The software’s ability to make the programming of industrial robots fast, easy, and efficient earned it the Game Changer Award for Motion Control at the 2013 RoboBusiness Conference. In 2015, CIO Review Magazine named us to its list of the 20 Most Promising Robotics Solutions Providers.