High Speed Savings

How the savings powerful high speed Air Turbine Spindles® deliver.

A customer slots 90 slots in each 6061 Aluminum on a Famup MC120 CNC, using a 2mm 2  Flute to slot at a 2,000 mm/min (79”/min) rate of advance. Each slot was 25 mm long, 2.5 mm wide and 4.3 mm deep and the operation was taking them 7 seconds per slot using their machine spindle. They hoped they could go faster.

Flute to slot at a 2,000 mm/min (79”/min) rate of advance. Each slot was 25 mm long, 2.5 mm wide and 4.3 mm deep and the operation was taking them 7 seconds per slot using their machine spindle. They hoped they could go faster.

With the governed 40,000 rpm, 0.88 HP 650 Spindle, cycle times were reduced to 2.8 seconds per slot. That meant a time savings of 6.3 minutes per part and on a 1,000 part order the time saving was over 100 hours.

The 650 Spindle saved this customer $20,500 on a single order based on a machine time cost of $20.00 per hour.

Upgrade Cost

The 650 Series 40,000 governed direct drive spindle including 2µ ER 11 Rego-Fix Collet System is only $5,250.00. The 650 paid for itself many times over in one job.

Air Turbine Spindles®

End users are always looking to optimize cutting tool performance. With Air Turbine  Spindles a continuous toolpath engagement, while maintaining high speed in angles even when working with hard materials for trochoidal milling. Their patented high torque governor and direct drives included in all Air Turbine Spindles, allows them to maintain high speed and torque up to 80 percent of the rated maximum power under cutting load.

Spindles a continuous toolpath engagement, while maintaining high speed in angles even when working with hard materials for trochoidal milling. Their patented high torque governor and direct drives included in all Air Turbine Spindles, allows them to maintain high speed and torque up to 80 percent of the rated maximum power under cutting load.

- Retrofit any CNC – just 90 PSI required

- Governed constant High Speed & Torque is maintained on the toolpath

- No Duty Cycle

- Direct Drive Reliability with ultra-low heat

- 2 Micron accuracy certified.

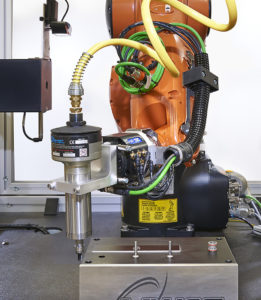

- Fully automated loading using rear air feed or our patented TMA Assembly (shown below)

Air Turbine Motors®

The high torque double turbine 1.4HP 450XHD is ideal for finishing metal or routing composites at governed 25,000, 30,000 and 40,000 rpm. Governor control of this patented  turbine increases air flow if rotational speed slows to maintain constant speed on the toolpath. The rotational speed stays high in the cutting process delivering a cleaner surface finish and faster cycle times.

turbine increases air flow if rotational speed slows to maintain constant speed on the toolpath. The rotational speed stays high in the cutting process delivering a cleaner surface finish and faster cycle times.

Light with low vibration the 450 is used in robotic milling, drilling and finishing and fixtured for routing and drilling plastics, woods, sandwich materials and composites faster and cleaner

Plus, oil free turbine direct Air Turbine Motors® ensure that plastics, composites or compounds and wood are not contaminated by oil mist emitted by traditional motors. Also, no maintenance is required and the motors are quiet, under 78 Dba.

Gearless Light & Powerful Angle Tools

Part finishing with less stress? Try the 40,000 rpm 2545SSVF – it’s unbelievably light and powerful. The 2545SSVF weighs just 18oz (0.50kg) and is available at governed 30,000  and 40,000 rpm. The operator merely guides the mounted point or bur with a light hand letting “speed do the cutting” with lower stress and reduced injury risk.

and 40,000 rpm. The operator merely guides the mounted point or bur with a light hand letting “speed do the cutting” with lower stress and reduced injury risk.

Uniquely, the entire motor is in the angle head and the vibration level is minimal. There are no gears to vibrate and wear out. This patented design eliminates problems with traditional tools and is very durable.

Available in multiple configurations: Short Handle SSVF version has front exhaust. Long handle front and rear exhaust versions available. Slide Valve (SV) or Trigger Switch Control (DM) options available. 90° 2590 Series also available.

About Air Turbine Tools

Air Turbine Tools® revolutionary constant high speed precision tools redefine performance standards for today’s high speed Hand Tools, Motors, and Spindles. From CNC, robotic and other mounted applications, to hand finishing operations, the unique technology employed in the design and manufacture of these products delivers a cleaner cutting action, faster production rates, and eliminates problems associated with traditional tools. Toolchanger Accessories make Air Turbine Spindles® easy to integrate on any CNC Machine (DMG, Haas, Robodrill, Doosan, Okuma, Makino, Mazak, Fanuc, Hurco, Brother, etc). Mill at 1,500″/min (38100 mm/min) with No Duty Cycle.

Visit www.airturbinetools.com to view the specifications of their products other options from Air Turbine Tools.