Air Turbine has been known for their innovative, high-speed spindles, hand tools, and motors. The 625LJS is the new member in the family of long body spindles.

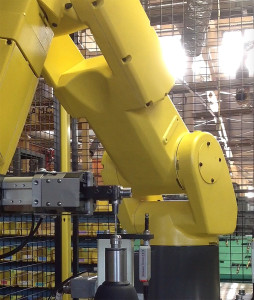

The patented 50,000 rpm 625LJS spindles from Air Turbine, are mounted in a stationary fixture to drill and edge finish aluminum parts with precision and non-stop work. At a constant, governed high speed, the process is considered faster and the surface finish will be finer.

The 625LJS is a new product in the Air Turbine Spindles® Long Body Series. The series is known for featuring extended bodies for deep pockets and concave molds. This lends itself to being perfect for lathes and various robotic applications. The 625LJS is available in both 50 mm or 100 mm body length.

The 625LJS is a new product in the Air Turbine Spindles® Long Body Series. The series is known for featuring extended bodies for deep pockets and concave molds. This lends itself to being perfect for lathes and various robotic applications. The 625LJS is available in both 50 mm or 100 mm body length.

The spindles are also oil free and operate below 67 dBA, making the 625LJS an excellent option for most shop environments. There is no need of an additional control system, or added need of lubrication. Additionally, there is no heat or electrical installation.

Accelerate your Production

With vibration at just 0.4mm/sec the 625LJS can produce superb accuracy and even faster results. The powerful 625LJS is designed for close workpiece operations and machines with very short z-axis travel. The compact and powerful Air Turbine Spindles® 625 unit delivers patented, constant, governed high speed operation under load up to 0.50 horsepower at 30,000, 40,000 or even 50,000 rpm.

This results in faster and cleaner cuts. Speeding up cycle times can achieving major savings. With fewer moving parts there is even less vibration and even less repairs.

Grease Free

There are no gears or vanes to lubricate or burn up. The ceramic grease packed bearings are durable, and for drilling the line of spindles includes angular bearings.

Totally oil free operation eliminates work piece contamination and oil lubrication using 90 PSI dry clean oil free air. The JS version is Air Turbine’s straight shank, and is easy to mount with an operator’s own selection of toolholder configurations. There are two selectable air inlet options, either through shank or the standard side airfeed National Pipe Thread Taper. The 625LJS has no duty cycle, allowing for continuous operation.

About Air Turbine

Air Turbine Tools® revolutionary constant high speed precision tools redefine performance standards for today’s high speed Hand Tools, Motors, and Spindles. From CNC, robotic and other mounted applications, to hand finishing operations, the unique technology employed in the design and manufacture of these products delivers a cleaner cutting action, faster production rates, and eliminates problems associated with traditional tools. Toolchanger Accessories make Air Turbine Spindles® easy to integrate on any CNC Machine (DMG, Haas, Robodrill, Doosan, Okuma, Makino, Mazak, Fanuc, Hurco, Brother, etc).

For more information, visit www.airturbinetools.com