DIGITALIZATION…THE FUTURE IS NOW

Myriad ways to boost productivity, enhance shopfloor flexibility and preserve data security…all on the market today for machine shops of many sizes

by: Ramona Schindler, Siemens Industry, Inc.

With the machine tool industry in flux currently, as it seeks to find its way into the digital

world, the entire process chain necessitates the integration of suppliers who can respond to the needs of the industry. The situation has very little “history” and so large end-customers and machine shops of all sizes are seeking assistance from their suppliers, while the machine tool builders are likewise seeking to partner with hardware, software, communications and controls suppliers to bring the most needed machine types to market.

Within this scenario, the large manufacturers focus on the “big picture” as they link their production departments, often located in different cities or even countries throughout the supply chain, while the small contract manufacturer with a dozen local customers wonders how this drive to the digital factory will impact their world— and it will. The good news is they can already utilize the IT, apps and communication devices onboard many of today’s advanced machine tools and the rapidly emerging skill sets of new workers in the machine tool industry to develop and implement the three basic levels of machine shop operations.

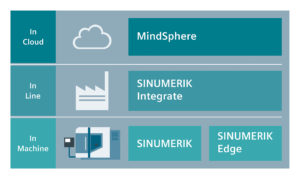

These levels comprise the communications hardware and protocols at the machine, the integration of inline machine production and the data resident in the cloud, which can be used today in many ways to boost productivity through automated analytics of the shopfloor’s utilization; to enhance shopfloor flexibility through optimized methods of production; and to preserve data security by state-of-the-art software solutions. In essence, the capture and manipulation of such data drives the productivity of a small shop or large production department in quite similar ways. The concept of your manufacturing seen as an eco-system, with information and control capabilities at all levels, can drive that “factory of the future” and, the good news, it can do so today.

From the CNC on your machines, whether they are number three in a mold shop or three hundred at a transmission plant, you can extract the pre-analytics that can be used to feed existing apps or to develop the most beneficial apps to suit your production scheme and workflow. The beauty of the app, whether you create your own, have a third-party integrator develop it or use existing solutions, is that it provides the hierarchy of information to your operator, line supervisor, plant operations personnel or global IT department in a similar manner. This scalability offers immediate benefit to manufacturers of all sizes and it does so, right now. For example, machine tool users can quickly and easily configure a CNC machine’s connections and ascertain its program status and operating mode. This will lead to increased manufacturing productivity, reliability and availability of the machine.

“The concept of your manufacturing seen as an eco-system, with information and control capabilities at all levels, can drive that “factory of the future” and, the good news, it can do so today.”

Cloud-based systems always raise the question of security issues, as the data flow in real time at high-speed and can be made accessible to many levels of information managers and operations personnel. It is critical that a thorough assessment of the access to that data precede the development of any communications protocol.

Digitalization is not necessarily a costly undertaking. First steps can be quickly implemented on the shopfloor, for example, through the use of small PCs like Raspberry Pi. Likewise, for the machine tool builder, the development of “digital twin” engineering, where a machine is fully designed, commissioned and test run in a virtual environment, is rapidly changing the playing field in this industry.

The number of connected machines is increasing exponentially and this is not simply engineering adornment, it is a necessary function for any manufacturer. Being able to quickly determine the overall equipment effectiveness (OEE) and conduct practical, beneficial predictive maintenance actions on your machines will contribute greatly to the production and profitability of your operation.

The management of today’s manufacturing shops and production departments have the challenge to become aware of all these available technologies and chart a course for their implementation. This is not a “someday” scenario; it is a vital journey for shops of all sizes, if they want to remain competitive in today’s changing market.

My last advice, look at digitalization as an umbrella for the secure shielding of smart data, not just big data. IIOT is the essential connectivity for all the elements of data on machine performance, materials flow, operations efficiency and ultimately your overall productivity.

It’s an exciting time in our business.

About Siemens USA

Siemens Corporation is a U.S. subsidiary of Siemens AG, a global powerhouse focusing on the areas of electrification, automation and digitalization. One of the world’s largest producers of energy-efficient, resource-saving technologies, Siemens is a leading supplier of systems for power generation and transmission as well as medical diagnosis. With approximately 348,000 employees in more than 190 countries, Siemens reported worldwide revenue of $86.2 billion in fiscal 2015. Siemens in the USA reported revenue of $22.4 billion, including $5.5 billion in exports, and employs approximately 50,000 people throughout all 50 states and Puerto Rico.

For more information, visit usa.siemens.com/cnc