Sandvik Coromant and Mastercam share new turning strategies with PrimeTurning™

Sandvik Coromant’s Mia Pålsson and Adam Johansson will present PrimeTurning™ at Modern Machine Shop’s Top Shops Conference 2017. Pålsson, head of the Product Unit Turning Tools and Johansson, part of the research and development team within the turning department, along with Stas Mylek from Mastercam, will compose a panel discussing the methodology of PrimeTurning.

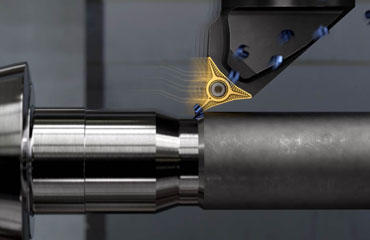

PrimeTurning enables turning in all directions resulting in a much more efficient and productive method compared to conventional turning. This approach facilitates a new turning method supporting CoroTurn Prime tools and a code generator. The panel will be discussing how Mastercam has incorporated PrimeTurning into a set of computerized toolpaths allowing users to reach higher productivity gains.

PrimeTurning enables turning in all directions resulting in a much more efficient and productive method compared to conventional turning. This approach facilitates a new turning method supporting CoroTurn Prime tools and a code generator. The panel will be discussing how Mastercam has incorporated PrimeTurning into a set of computerized toolpaths allowing users to reach higher productivity gains.

Modern Machine Shop’s Top Shops Conference will be exhibiting some of the industry’s leading trends allowing members of the industry to share their best practices. Partnered with Mastercam, Sandvik Coromant is bringing the industry’s first automated CAM (Computer Aided Manufacturing) support to PrimeTurning. Together, Mastercam and Sandvik Coromant will release a new set of turning strategies, scheduled to be issued in June 2018, supporting CoroTurn® Prime inserts and PrimeTurning technology. This new technology and CAM programming will grant users the flexibility to do turning in all different directions, higher machine utilizations, faster metal removal rates, longer lasting inserts and an increase in productivity anywhere from 50%-80%.

With a background in material science, Mia Pålsson has worked at Sandvik Coromant for the last 26 years. During her time, Mia has developed and broad scope of skills covering production, R&D, product management and marketing. In 2014, Mia was nominated one of the top three leadership developers in Sweden by the Magazine “Chef.” Today, she coaches managers in the Sandvik Leadership training programs alongside her heading Product Management and R&D for Turning Tools.

Adam Johansson has been heavily involved in the invention and development of Sandvik Coromant’s newest products and solutions in general turning. Adam studies customer needs and demands and utilizes that information to improve Sandvik Coromant’s processes by cultivating new creative methods in metal cutting. Adam holds a master’s degree in mechanical engineering from Luleå University of Technology, Sweden and was nominated for the Sandvik Innovation Prize.

Visit www.topshopsevent.com for more information about Modern Machine Shop’s Top Shop Conference 2017 held at the JW Marriott in downtown Indianapolis.

Sandvik Coromant

Part of global industrial engineering group Sandvik, Sandvik Coromant is at the forefront of manufacturing tools, machining solutions and knowledge that drive industry standards and innovations demanded by the metalworking industry now and into the next industrial era. Educational support, extensive R&D investment and strong customer partnerships ensure the development of machining technologies that change, lead and drive the future of manufacturing. Sandvik Coromant owns over 3100 patents worldwide, employs over 8,000 staff, and is represented in 150 countries.

For more information visit www.sandvik.coromant.com or join the conversation on social media.