Operational assets are at the heart of business operations and failure can not only affect business critical processes and cause downtime but also endanger people and equipment.

Operational assets are at the heart of business operations and failure can not only affect business critical processes and cause downtime but also endanger people and equipment.

A well-planned maintenance strategy is a key factor of an organization’s asset management strategy that strongly lends towards mitigating the risk of asset failure. The results of an effective maintenance strategy are extensive for operations.

Maintenance staff responsible for the execution of an asset performance management program typically aim for strategies that produce reliable asset capacity whilst minimizing operational and equipment lifecycle costs.

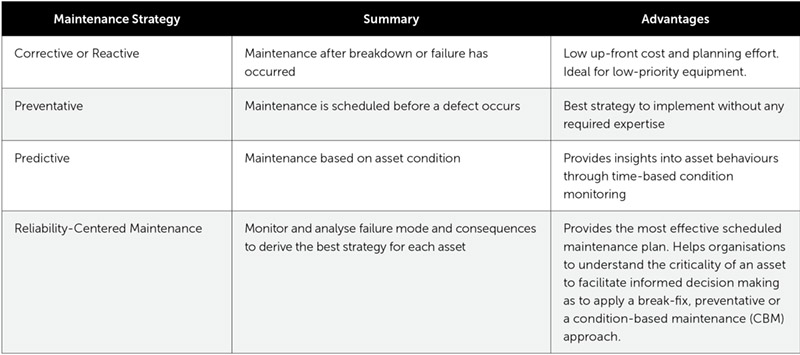

While maintenance approach depends on organization’s unique requirements, financial capability, ability and culture, the following cover the most commonly used type:

Corrective or reactive maintenance

Corrective maintenance, also referred as run-to-failure is carried out upon failure detection, whereas reactive maintenance is where equipment is repaired after wear, breakdown or malfunction to enable an asset to perform its intended function. Although these involve low short-term costs and require minimal planning, however, corrective and reactive maintenance actions result in unplanned additional costs, asset’s lifetime decrease and operational delays.

The proactive maintenance model combines intentional preventive and predictive interventions to maintain an asset in reliable and operable condition.

Preventative maintenance

Time based proactive approach, involves performing periodic inspections, preventative maintenance prevents machine failures from occurring. This model keeps assets more efficient and extends their operable life, avoiding unforeseen breakdowns. Preventive maintenance appears costly and time-consuming at the beginning, it most often proves to be a solid return on investment by reducing the number of major breakdowns as well as the asset’s downtime.

Traditionally, maintenance teams relied on preventative maintenance schedules provided by the manufacturer, including regularly replacing asset components based on a suggested timeline. However, these timelines are only an estimate of when an equipment will require service, and the actual use of the equipment can significantly affect the reliability of OEM estimates.

Traditionally, maintenance teams relied on preventative maintenance schedules provided by the manufacturer, including regularly replacing asset components based on a suggested timeline. However, these timelines are only an estimate of when an equipment will require service, and the actual use of the equipment can significantly affect the reliability of OEM estimates.

A well-planned preventative maintenance strategy can provide visibility of routine maintenance and any statutory compliance requirements.

Predictive Maintenance

Predictive maintenance involves a condition-based process, forecasting when a physical asset failure can occur and facilitate maintenance at the right time. This is achieved through monitoring the condition of the asset through data from machine sensors and smart technology to alert the maintenance team when a piece of equipment is at risk of failing.

Even though predictive maintenance can be carried out via visual inspections of equipment, but the effective way to establish a predictive maintenance strategy is by using an Enterprise Asset Management (EAM) to track sensor data or meter readings.

In the recent times, digitalization via the Internet of Things (IoT), has aided in the improvement of predictive maintenance routines.

Reliability-Centered Maintenance (RCM)

The reliability-centered maintenance, a multi-factor approach is a highly involved process that takes into account all the possible failure modes to derive a custom maintenance plan for each individual asset. The outcome of a successful RCM program is the definition and implementation of a specific maintenance strategy on the most critical assets of the facility.

Asset-intensive companies emphasize on reliability, availability and safety in order to achieve world class performance by replacing reactive maintenance strategies with proactive strategies such as RCM and total predictive maintenance.

Poor maintenance practices can lead to decreasing availability and productivity as the operational assets’ condition deteriorates thus escalating maintenance costs arising from incremental breakdown frequency. To address these challenges requires a shift from reactive maintenance to preventative maintenance paradigm. Enabling preventative strategies would produce a small delay in order to prevent possible larger delays. Preventive maintenance allows the maintenance team to focus on high-level priorities. Elevating the maintenance planning from a tactical approach to strategic can help extend the life of critical assets. Once a reliability and maintenance policy and associated improvement strategy are in place, it requires constant refining to keep abreast of the dynamic demands of the industry and organization.

Furthermore, the following five step strategy will help your organization establish a world-class preventive maintenance program and experience the resulting operational gains.

1. Review the Current Maintenance Strategy

1. Review the Current Maintenance Strategy

An insight into the current asset portfolio and maintenance programs will help understand key gaps and areas for improvement.

2. Determine Systemised Operating Procedures for Reactive and Preventative Maintenance

Simple procedures outlining the types of tools to be used on particular maintenance requests and establishing standardized operating procedures across the board can greatly improve the outcomes from both reactive and preventative maintenance.

3. Set Up A Reliability and Maintenance Policy with An Improvement Plan

Planning is the key to becoming more cost-effective with the asset maintenance activities. Establish a sound reliability and maintenance policy that incorporates an improvement plan to prevent failure.

4. Attain Perfect Execution of Preventive Maintenance in Line With The Industry Rule

Sporadic preventive maintenance practices can limit the effectiveness of the maintenance procedures. Practice ten percent rule of preventative maintenance i.e., the task must be executed within a ten percent variation of the time frequency of the request.

Example, a 60-day preventative maintenance activity must be completed within three days on either side of the due date for optimal maintenance outcomes, therefore propelling into a world-class preventative maintenance organization.

5. Leverage Technology To Advance Your Preventative Maintenance Program

Over the past decade, automation using the right technology has significantly helped asset-intensive organizations reduce costs, both from an operational and people standpoint.

An Enterprise Asset Management solution can provide the key technology enabler for an organization to realize these benefits through the implementation a preventative maintenance approach to managing its operational assets. An effective EAM will reduce breakdowns and improve availability and productivity of critical assets through a risk-based preventative maintenance approach aligned to service, cost and risk outcomes.

Leveraging business and asset intelligence via reporting capabilities offer maintenance departments the opportunity to showcase activities and the ways to obtaining key performance indicators.

Once a reliability and maintenance policy and associated improvement plans are in place, it requires constant refining to ensure it meets the dynamic demands of the industry and organization. In fact, organizations with world-class preventative maintenance programs assess the current state of the program quarterly and how it can be improved. Once established, it opens doors to extend an organization’s maintenance program beyond that by integrating predictive maintenance techniques and technologies. Asset availability is directly correlated with the company’s maintenance strategy. Reactive maintenance generally yields lower asset availability than preventative models which is lower than predictive which is lower than Condition Based Maintenance approach.