In the world of metalworking, safety is paramount. The use of metalworking fluids (MWF) is essential for the cutting, grinding, and machining processes that form the backbone of manufacturing. However, these fluids, while crucial for cooling and lubricating tools, can pose significant health risks to workers if not properly managed. With the increasing focus on workplace safety and efficiency, innovations like Bolb’s SUVOS BioCleanse UVC module are revolutionizing how industries approach MWF management.

The Hidden Dangers of Metalworking Fluids

Metalworking fluids are vital in reducing heat and friction during machining processes. However, they are also prone to contamination by microorganisms such as bacteria and fungi, which can lead to biofilm formation. These contaminants not only degrade the quality of the fluid but also pose severe health risks to workers. Exposure to contaminated MWFs can cause a range of health issues, including dermatitis, respiratory problems, and even more severe conditions like sepsis or chronic lung diseases.

Additionally, the presence of biological contaminants can lead to unpleasant odors, making the work environment uncomfortable and potentially hazardous. Traditional methods of managing these fluids often involve the use of harsh chemicals or frequent fluid replacement, both of which have their drawbacks, including increased costs, environmental impact, and potential safety risks associated with handling chemicals.

A New Era in Safety: The SUVOS BioCleanse Solution

A New Era in Safety: The SUVOS BioCleanse Solution

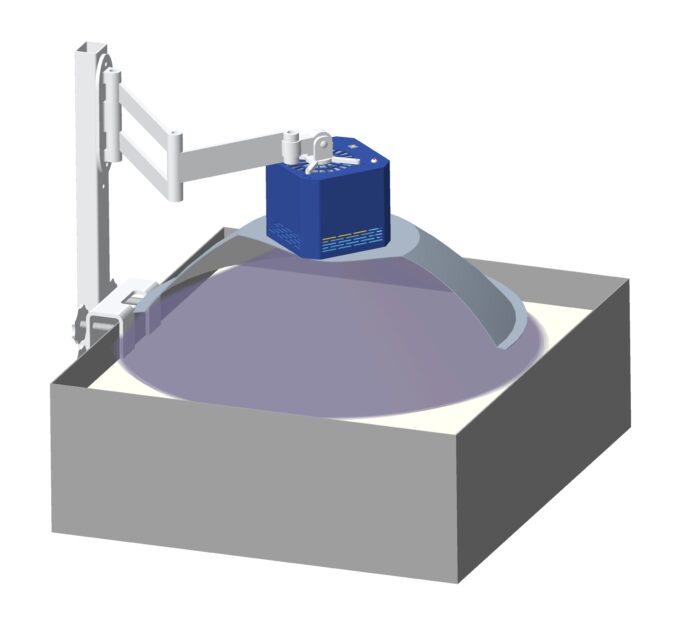

Enter Bolb’s SUVOS BioCleanse UVC module, a cutting-edge solution designed to tackle the issues associated with MWF contamination head-on. The SUVOS BioCleanse leverages UV-C LED technology to deactivate or eliminate biological contaminants present in MWFs, thus extending the life of these fluids while simultaneously enhancing worker safety.

The technology works by emitting UVC light, which breaks down the DNA and RNA of harmful microorganisms, effectively stopping their growth and reducing the risk of contamination. This process not only keeps the fluids cleaner for longer periods but also helps in maintaining the pH balance, which is crucial for preventing corrosion and maintaining the effectiveness of the MWFs.

Safety and Cost-Effectiveness: A Dual Benefit

The implementation of SUVOS BioCleanse offers a dual advantage: improving safety while reducing costs. According to early adopters like T&K Machine, the technology has revolutionized their CNC machine maintenance processes. By eliminating the need for constant maintenance and fluid replacement, companies have reported significant savings—up to $2,000 per machine per year. This reduction in downtime, labor, and disposal costs adds up quickly, making it a financially sound investment.

But the benefits extend far beyond cost savings. By maintaining cleaner fluids, the risk of worker exposure to harmful contaminants is drastically reduced, leading to a safer and more comfortable working environment. This is particularly important in industries where compliance with safety standards is not just a matter of regulatory obligation but a core component of operational excellence.

Case Study: Implementing SUVOS BioCleanse in Real-World Settings

T&K Machine’s experience with SUVOS BioCleanse underscores its effectiveness. By incorporating this technology into their MWF management system, they have not only improved the quality of their cutting and cooling processes but also enhanced overall workplace safety. The technology’s ability to extend the life of MWFs from weeks to months without the need for chemical additives or frequent replacements highlights its potential to transform the industry.

Moreover, the use of SUVOS in centralized treatment systems capable of handling large volumes of MWFs has shown that even in high-capacity environments, the technology remains efficient and effective. The reduction in odors, the elimination of harmful biological hazards, and the overall improvement in the working environment make SUVOS BioCleanse a valuable addition to any metalworking operation.

Looking Ahead: The Future of MWF Management and Workplace Safety

As industries continue to prioritize both efficiency and safety, innovations like SUVOS BioCleanse are likely to become standard practice. The integration of such technologies into the broader framework of workplace safety not only protects workers but also enhances operational efficiency and reduces environmental impact.

For companies looking to improve their safety standards and operational efficiency, investing in advanced MWF management solutions like SUVOS BioCleanse offers a clear path forward. As the technology becomes more widely adopted, we can expect to see a significant reduction in the health risks associated with metalworking, alongside increased productivity and cost savings.

The adoption of Bolb’s SUVOS BioCleanse technology marks a significant step forward in the quest for safer, more efficient metalworking environments. By addressing the challenges posed by MWF contamination with innovative UVC technology, industries can protect their most valuable assets—their workers—while also enhancing their bottom line.

As the technology becomes more widely adopted, we can expect to see a significant reduction in the health risks associated with metalworking, alongside increased productivity and cost savings.