The foundation for the Schaeffler Group as it is known today was laid in 1946 when brothers Dr. Wilhelm Schaeffler and Dr.-Ing. E.h. Georg Schaeffler launched Industrie GmbH in Herzogenaurach, Germany. The company’s rise began in 1949 when Dr. Georg Schaeffler invented the cage-guided needle roller bearing, which was swiftly followed by the large-scale production of INA needle roller bearings for the German automotive industry. Today, INA is part of the Schaeffler Group, whose portfolio of product brands also includes FAG and LuK.

The foundation for the Schaeffler Group as it is known today was laid in 1946 when brothers Dr. Wilhelm Schaeffler and Dr.-Ing. E.h. Georg Schaeffler launched Industrie GmbH in Herzogenaurach, Germany. The company’s rise began in 1949 when Dr. Georg Schaeffler invented the cage-guided needle roller bearing, which was swiftly followed by the large-scale production of INA needle roller bearings for the German automotive industry. Today, INA is part of the Schaeffler Group, whose portfolio of product brands also includes FAG and LuK.

After following its automotive customers around the world – Volkswagen in particular –Schaeffler eventually made landfall in the U.S. as a joint venture with Textron in 1964. Schaeffler became the sole proprietor of the business in 1969, ultimately establishing its North American headquarters in Fort Mill, South Carolina. This campus now features two administration buildings, an R&D center, and two manufacturing facilities: one dedicated to bearings for transmissions, and the other to linear bearings. The company has 11 additional manufacturing plants and over 13,000 employees throughout North and South America.

According to Ulrich “Uli” Mayr, vice president of Industrial Automation, Americas, U.S. activities are basically divided into three divisions; Automotive Technologies, Automotive Aftermarket, and Industrial. “In the first category, we are focusing on engine components, transmission, chassis, and e-mobility to automakers such as Ford, GM, and Chrysler,” he says. “Aftermarket replacement parts enter the market through all the major automotive aftermarket distributors and they are labeled as Schaeffler or LuK, which is known for its clutches.”

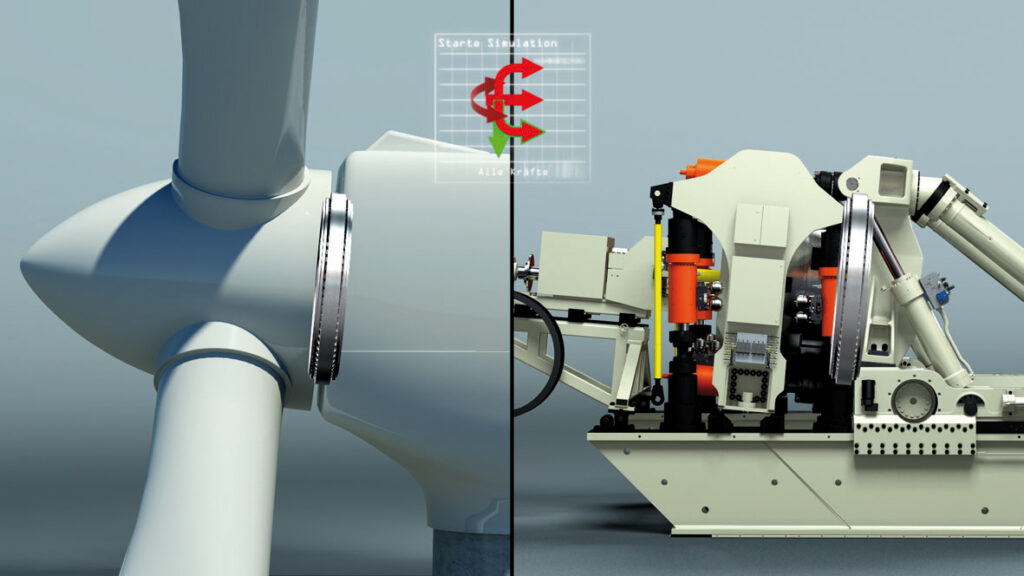

The Industrial division, Mayr’s specialty, is defined by markets rather than products. They include off-road (think John Deere and Caterpillar) wind turbines, two-wheelers (such as Harley-Davidson), railway, raw materials (mining and oilfield), power transmission, industrial automation (machine tools, medical manufacturing), and aerospace. Mayr goes on to say that Schaeffler’s sales and application engineers conduct due diligence on each customer so that they understand their processes and potential challenges to the greatest extent possible at the beginning and throughout their relationship. They listen to end-user concerns and take them back to R&D for possible incorporation into future design improvements from which everyone benefits. This approach has resulted in some 2,400 patents being awarded to the Schaeffler Group in 2019 alone – making it Germany’s second-most innovative company, according to the German Patent & Trademark Office (DPMA).

The Industrial division, Mayr’s specialty, is defined by markets rather than products. They include off-road (think John Deere and Caterpillar) wind turbines, two-wheelers (such as Harley-Davidson), railway, raw materials (mining and oilfield), power transmission, industrial automation (machine tools, medical manufacturing), and aerospace. Mayr goes on to say that Schaeffler’s sales and application engineers conduct due diligence on each customer so that they understand their processes and potential challenges to the greatest extent possible at the beginning and throughout their relationship. They listen to end-user concerns and take them back to R&D for possible incorporation into future design improvements from which everyone benefits. This approach has resulted in some 2,400 patents being awarded to the Schaeffler Group in 2019 alone – making it Germany’s second-most innovative company, according to the German Patent & Trademark Office (DPMA).

That number is bound to rise. Just take a look at the company’s robotics portfolio. In 2020 Schaeffler introduced the new XZU bearing, with 20 percent less friction and 30 percent greater rigidity for articulating arm positions. This bearing is the culmination of 70 years of experience in the design and manufacture of needle roller bearings. This same bearing is also used as the main bearing of its new precision gearbox (RTWH); a silk hat-type strain wave generator speed reducer. The RTWH combines high gear ratios with relatively lightweight construction for clearance-free operation, high positioning accuracy, and compactness. The RTWH offers gear reductions of up to 150:1.

Also creating a stir are the new Vacrodur spindle bearings, which provide a service life that is 25 times longer (under mixed-friction conditions) as compared to 52100 steel, 2.4 times higher in terms of dynamic load carrying capacity, while offering much better thermal stability at higher temperatures.

Also creating a stir are the new Vacrodur spindle bearings, which provide a service life that is 25 times longer (under mixed-friction conditions) as compared to 52100 steel, 2.4 times higher in terms of dynamic load carrying capacity, while offering much better thermal stability at higher temperatures.

Since bearings are generally acknowledged as the leading cause of expensive spindle failure events, improvements on this scale are welcome news. Decreasing downtime, as well as maintenance, repair, and replacement costs, is an accomplishment to be celebrated.

“This is a publicly-traded company that is still majority-owned by the Schaeffler family, which is rare these days,” says Mayr, “and we’re celebrating the 70th anniversary of Dr. Schaeffler’s invention of the cage-guided needle roller bearing, which remains our original claim to fame. And I think we do our best to live up to that every day.”