October 24, 2024 – FABTECH 2024, one of the largest metal forming, fabricating, welding, and finishing exhibitions in North America, showcased numerous industry leaders pushing the boundaries of manufacturing technology. Among them, HYDMECH stood out with its impressive lineup of machinery and forward-thinking approach to fluid power solutions. We had the opportunity to sit down with Rick Arcaro, Vice President of Sales and Marketing at HYDMECH, to gain deeper insights into the company’s legacy, innovations, and future directions.

A Legacy of Excellence: Meet Rick Arcaro

With 27 years at HYDMECH and nearly four decades in the industry, Rick embodies the company’s dedication and expertise. “I’ve been with the company since 1986, and it’s only the third job I’ve ever had. It’s a great industry—addictive, really. You get to see new stuff every single day; you’re never stale,” he shared enthusiastically.

Rick’s long tenure at HYDMECH underscores the company’s stable and nurturing work environment. “Working for HYDMECH is fantastic because we’re not a stale company. We’re very progressive, innovative, and just a great place to work. We have a lot of good people,” he added, highlighting the company’s strong internal culture and commitment to employee satisfaction.

What Sets HYDMECH Apart?

When asked about what distinguishes HYDMECH’s products from competitors, Rick provided a comprehensive overview. “Our machines are bar none the easiest to run in the industry,” he stated confidently. This ease of operation is a significant differentiator in a market where labor shortages and the need for efficient training are pressing concerns.

One of HYDMECH’s standout features is their user-friendly interface. “We’re the only machine tool builder that actually gives you a directions door chart in our PLC on our machine, how to run it. So if your operator’s not there today, somebody can come over and be a saw operator and keep your production going.” This level of accessibility ensures that even less experienced operators can manage the machinery effectively, minimizing downtime and maintaining productivity.

Rick also emphasized the practicality of HYDMECH machines in terms of maintenance and part replacement. “Our machines are built with a lot of common components. Anything on a saw that we don’t machine, weld or fab, you can buy at a local supply house. So supply chain issues, replacement parts are very simplistic on HYDMECH machines.” This approach not only reduces operational costs but also enhances the reliability and longevity of their equipment.

Driving Innovation in a Changing Market

Innovation remains at the core of HYDMECH’s strategy. “Keeping up with the market, one thing coming out of COVID taught a lot of people, how to deal with supply chain, but more so how to deal with labor and I believe more the lack of labor,” Rick explained. The pandemic highlighted the vulnerabilities in global supply chains and exacerbated the existing labor shortages, prompting companies like HYDMECH to adapt and innovate.

To address these challenges, HYDMECH focuses on making their machines as easy and simple to operate as possible. “Our machines have to be easy, simple, and non-intimidating to run. So that basically, again, distinguishes us from some of the other competitors” Rick noted. This user-centric design philosophy ensures that businesses can maintain high production levels even with a limited pool of skilled labor.

Rick highlighted several key innovations in HYDMECH’s new product line. “The innovations we have are easier to operate than they were 10 years ago, 15 years ago. Our production levels are higher. A lot of that’s due to components on machines. In fairness to our market, a lot of it’s due to the blades. We build the machine, we don’t build the blades. The innovation of blades have come a long way in the last 10 years as well.”

Furthermore, HYDMECH is expanding its reach into automation. “We sell automation daily. The sawing market has now held a bit of a different standard. 10, 12 years ago, “a saw is a saw”. Now they’re referred to as machine tools. And it’s a big difference. And you’ve got people buying high-end sheer press brakes and lasers, and now our machines are going next to them.” This shift signifies HYDMECH’s commitment to integrating advanced technologies that align with the evolving demands of modern manufacturing.

Targeting a Diverse Market

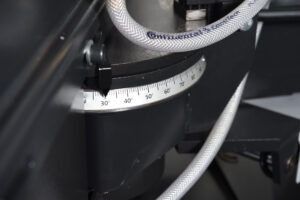

HYDMECH’s versatility is a key strength, allowing them to cater to a broad spectrum of industries. “HYDMECH for a lot of years has always been a leader in fabrication. A lot of our machines have the capability to miter cut angles, shapes, products. That’s where the business started. The owner of the company was the innovator of the first bandsaw machine where the head moved instead of the material,” Rick recounted.

The company’s flagship machine, the S-20, stands as a testament to their innovative spirit. “If you go out and Google an S-20, it’s the highly most recognized machine name and brand in the world. It’s the most copied machine name and brand in the world. So that’s got to be some sort of flattery. We must be doing something right.”

Over the years, HYDMECH has expanded its capabilities beyond fabrication to compete in the chip market. “We’ve developed a much better standard of just straight cutting for the chip industry. Where we hung our hat in fabrication, we’ve certainly now compete daily in the chip market. So we’ve become a very large Swiss Army knife type company that we can walk into the small two-person machine shop to the service centers of automotive plants, forgers that may be employing 300 people. We fit all market segments,” Rick elaborated.

This adaptability ensures that HYDMECH can serve a wide range of clients, from small businesses to large industrial operations, providing tailored solutions that meet their specific needs.

Commitment to Quality and Sustainability

HYDMECH’s commitment to quality is evident in every aspect of their operations. “Quality is at the core of HYDMECH’s operations. We adhere to stringent quality control processes and hold various certifications, including ISO 9001 and ISO 14001,” Rick emphasized.

Moreover, HYDMECH is dedicated to sustainable practices and corporate social responsibility. “We implement eco-friendly manufacturing processes, minimize waste, and strive to reduce our carbon footprint. Additionally, HYDMECH engages in community initiatives and supports various social causes, reinforcing our role as a responsible corporate citizen,” Rick highlighted.

This holistic approach not only enhances the company’s reputation but also aligns with the growing emphasis on sustainability within the manufacturing sector.

Global Reach and Exceptional Customer Support

With a global footprint, HYDMECH ensures that its products are accessible to customers worldwide. “We serve customers across different continents, ensuring that our products are accessible wherever needed,” Rick stated. “We pride ourselves on providing excellent customer support, offering technical assistance, maintenance services, and training to ensure optimal performance of our products in the field,” Rick added.

This comprehensive support system ensures that customers can maximize the efficiency and longevity of their HYDMECH machinery, fostering long-term partnerships and customer loyalty.

Promotions and Future Outlook

Promotions and Future Outlook

As FABTECH 2024 closed, HYDMECH is keen on maintaining its momentum. “HYDMECH’s offering a package on our machines. From now until mid-December, we’re offering a 7% discount on several of our machines and accessories and packages. So we’re looking to keep our backlog moving,” Rick announced.

However, the company is experiencing high demand, with bookings already filling into early 2025. “One challenge for us is we’re already booking into 2025 Q1, unfortunately some Q2. We’ve had a very good year and I’m certainly not going to apologize for that for lead times, but it’s a challenge. I still got to give somebody an incentive to wait for a HYDMECH because there are other choices out there. So I believe we’re worth the wait,” Rick assured.

This robust demand reflects HYDMECH’s strong market position and the trust that customers place in their products. The company’s ability to consistently deliver high-quality, reliable machinery ensures that it remains a preferred choice in a competitive landscape.

Looking Ahead

As the manufacturing landscape continues to evolve, HYDMECH remains poised to lead with innovation and adaptability. Rick Arcaro’s insights at FABTECH 2024 revealed a company that not only honors its rich legacy but also embraces the future with cutting-edge technology and a customer-centric approach.

“HYDMECH is a unique company in that area,” Rick concluded. “We strive to reduce material handling, optimize processing, and give operators the tools they need to run multiple machines efficiently. This focus on innovation and efficiency sets us apart and ensures that we continue to meet the diverse needs of our customers.”

With its unwavering commitment to quality, innovation, and customer satisfaction, HYDMECH is well-positioned to navigate the challenges of the modern manufacturing industry and continue its trajectory of success.