Headquartered in Cincinnati, Ohio – with additional locations in Brookfield, Wisconsin, and Moline, Illinois – Exact Metrology was launched in 2000 as a seller of top-line 3D scanning and measurement devices. The co-founders, Steve Young and Dean Solberg, soon discovered there was an equal demand for contract services, when companies had short-term needs that didn’t justify making equipment purchases. That led to its current business model, Young says.

Headquartered in Cincinnati, Ohio – with additional locations in Brookfield, Wisconsin, and Moline, Illinois – Exact Metrology was launched in 2000 as a seller of top-line 3D scanning and measurement devices. The co-founders, Steve Young and Dean Solberg, soon discovered there was an equal demand for contract services, when companies had short-term needs that didn’t justify making equipment purchases. That led to its current business model, Young says.

“About 50 percent of our business involves contract scanning services, with the rest divided between rental and new and used equipment sales,” he explains. “The majority of our customers are located in North America, although we’ve had a number of projects with companies around the world.”

However the company has evolved, it has remained true to its original commitment to be independent in terms of the equipment lines it chose to work with, represent, and sell. Not only has this proven to be an attractive lure to potential contract scanning customers, it has led to the success of its equipment sales and leasing operations. “When you’re working with OEMs like Hexagon, Zeiss, Artec, Leica and Polyworks, you have a very nice portfolio of scanning and measuring equipment to offer your customers, whether as a service provider or a sales resource. When you add all the other OEMs we represent, I really think it supports our claim that we offer our customers “every tool in the toolbox,” which is not an exaggeration.”

But it also offers its expertise. For example, it can help a company determine whether its needs for 3D scanning services are best met cost-wise by a service contractor at a particular point, or if it’s time to make a capital investment for onsite capabilities.

“Maybe a company only needs a product they’ve developed scanned once,” he says. “That’s when we’d steer them toward contract services, where we would provide the data they require as a service provider.

“Maybe a company only needs a product they’ve developed scanned once,” he says. “That’s when we’d steer them toward contract services, where we would provide the data they require as a service provider.

“Once that product moves into production, though, we’ll help them take a look at the cost benefits of bringing scanning and measurement technologies in house, backed by our expertise in representing such high-caliber OEMs in such a number of different capacities – sales, rental, contract service, etc.,” he says. “You want to make sure the workload justifies the investment in new technologies or equipment.”

Building on this theme, Exact also offers consulting services, beginning with site visits to make suggestions about potential improvements to a company’s current production model.

This type of support is augmented by inspection and staffing services, custom CMM programming, and software training. “If a company has acquired another one and needs assistance getting their systems in synch, we can help,” Young says, “or if critical team members are taking an extended leave for whatever reason, we can step in and fill that space as well.”

Asked whether the pandemic has affected Exact’s mode of operation, Young says that it’s mostly come in the area of sales. “We’re doing more online demos than we once did, which allows us to perform these for probably three more potential customers a day than we used to when we were physically travelling to meet them.”

Still, he’s looking forward to a time when U.S. manufacturers can begin meeting and doing business in a more personal fashion again. “That’s an important component of the industrial marketplace,” Young says. “I think it’s going to be great once we can come back together again to discuss the future of manufacturing.”

Exact Services at a Glance

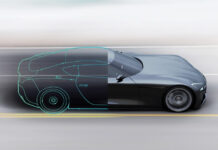

3D Scanning

Inspection

Reverse Engineering

Long Range Scanning

Scan to CAD

CT Scanning

3D Scanning Technologies

Portable Articulated Arm

Blue Light Scanner

Computed Tomography CT

Automated Robotic Scanners

Laser Scanning

Laser Tracker

Long Range Scanner

Hand-Held Scanners