Founded in Bautzen, Saxony, as an iron foundry in 1867, and eventually relocated to Salach, Baden-Württemberg, in southern Germany, where it branched out into lathes and other specialty machines — and where it is still headquartered today — EMAG is a global entity with a heavy presence in every conceivable industrial market, both geographically and in terms of activity. This includes facilities in China, Japan, Korea, Russia, India, Mexico, and Brazil, among many others, with a host of complementary specialized brands that have been acquired over the years (see sidebar). It established its North American headquarters in 1980, where it oversees operations in the United States and Canada from Farmington Hills, Michigan.

Founded in Bautzen, Saxony, as an iron foundry in 1867, and eventually relocated to Salach, Baden-Württemberg, in southern Germany, where it branched out into lathes and other specialty machines — and where it is still headquartered today — EMAG is a global entity with a heavy presence in every conceivable industrial market, both geographically and in terms of activity. This includes facilities in China, Japan, Korea, Russia, India, Mexico, and Brazil, among many others, with a host of complementary specialized brands that have been acquired over the years (see sidebar). It established its North American headquarters in 1980, where it oversees operations in the United States and Canada from Farmington Hills, Michigan.

According to Kirk Stewart, vice president of sales, North America, the network for which he is responsible provides insights into the way the company conducts its business around the world. “We take a three-pronged approach,” he explains. “We don’t work through third party sales channels. All the members of our sales team are EMAG employees. First, we have a regional sales force of nine specialists centrally located throughout the United States and Canada. Then we have three key account managers who work directly with our large automotive customers, and finally a technical sales force that’s dedicated to electro chemical machining, particularly for aerospace applications.”

This structure is a result of the company’s very DNA, if you will. From the very beginning, EMAG has been known for its turnkey solutions, working directly with customers to tailor its machine tools to their exact specifications. Taking the United States as an example, in the 1990s through the early 2000s, EMAG was heavily involved with the automotive industry, working closely with OEMs and Tier 1 engineers on design variations that would allow them to meet their production goals in terms of quality, throughput, and technical machine specifications. This hands-on approach remains deeply ingrained the company’s customer service philosophy, Stewart says.

At the same time, market needs shift, and in 2011 EMAG recognized a growing demand for machine tools that could ship quickly, at a lower price point, and therefore within range to a broader field of manufacturers. The machines, known as the “modular standard” line, could be stocked anywhere in the world, are available for immediate shipment, ready to be plugged in and put to work. By 2014, these machine tools were being sold around the world, and EMAG was seeing approximately 30 percent of its U.S. sales coming from operations with fewer than 100 employees; a figure it had never seen before. This standardization has led to lower build costs for the OEM, and quicker delivery for its customers, among other benefits — making the machines available to a different subset of the market. And the broadening customer base has resulted in new experiences for EMAG with materials including Inconel and titanium. This added material knowledge will be applied to future jobs, expanding the range of EMAG’s expertise.

Another service EMAG provides is a “systems division” that can provide customers with assistance in integrating multiple EMAG machines and technologies, as well as whatever peripheral devices they might need for a custom cell or production line, whether that be a washer, polisher, or marker. If additional components are necessary, the company will offer the customer its choice of third-party OEM for the necessary pieces of equipment, or it will choose from its list of established vendors, in order to deliver a complete turnkey system that is production ready.

Another service EMAG provides is a “systems division” that can provide customers with assistance in integrating multiple EMAG machines and technologies, as well as whatever peripheral devices they might need for a custom cell or production line, whether that be a washer, polisher, or marker. If additional components are necessary, the company will offer the customer its choice of third-party OEM for the necessary pieces of equipment, or it will choose from its list of established vendors, in order to deliver a complete turnkey system that is production ready.

Looking to the future, Stewart sees many possibilities for growth, but has seen particular customer interest in the area of lasers. “We have come to find that ‘laser cleaning’ of seams prior to gluing or welding presents a superior alternative to aqueous cleaning, preparing the surface more thoroughly in order to achieve a stronger, more secure bond. We’re also excited about laser hardening for a number of reasons. First of all, the process really does a good job on parts with complex geometries, penetrating all the angles and channels that other methods might miss, and you also have more control over the exact point or area you’re targeting. This is especially important for thin-wall structures, where the goal is to decrease the overall weight of the part while maintaining strength.”

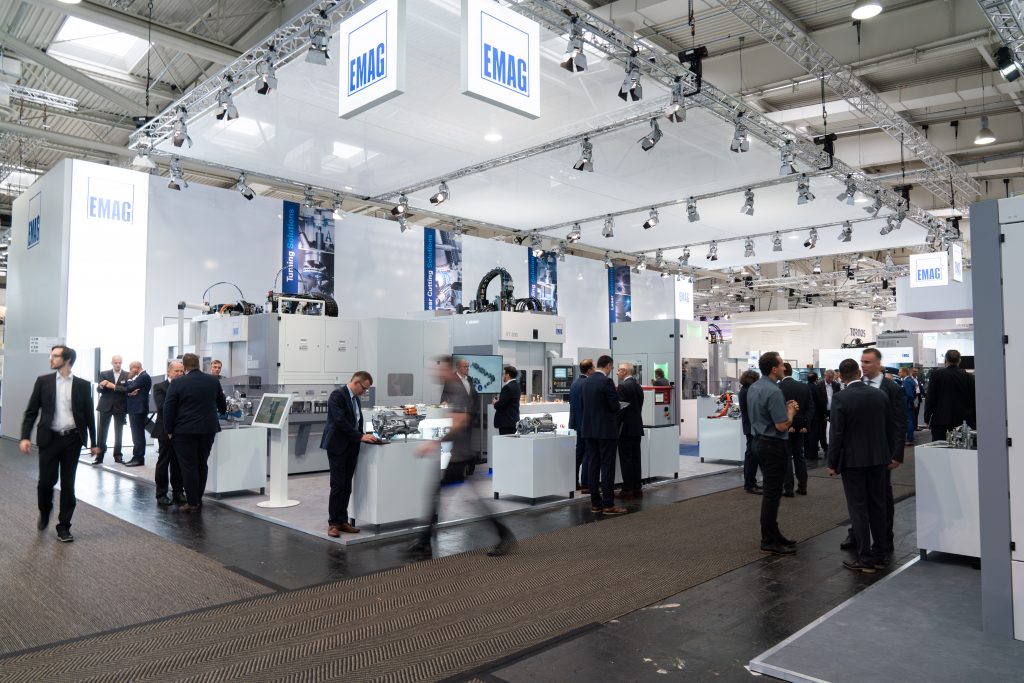

Whether EMAG is attending IMTS or EMO — or any of the dozens of expos where it’s found around the world each year — Stewart says the company’s capability’s and expertise make it a pleasure to continue to update systems for existing customers and to begin relationships with new ones. “Whether we’re talking about the milling and turning of round parts or the induction hardening of powertrain components, we’re in a position to have a ‘complete process’ discussion, that allows you to perform every necessary operation onsite.

Brands within the EMAG Group:

EMAG: Turning, Milling, Drilling

Reinecker: Internal Precision Grinding

Karstens: External Cylindrical Grinding

Kopp: Camshaft Grinding

Naxos-Union: Crankshaft Grinding

KOEPFER: Gear Hobbing

LaserTec: Joining and Laser Welding

ECM: Electro Chemical Machining

eldec: Induction Hardening

Richardon: Power Skiving