Anyone who owns, operates, or works in an industrial facility knows the importance of removing harmful dust from the air. However, as production techniques and materials modernize at an alarmingly swift pace, the combustibility of the dust created is now a major concern. Increasingly, leaders in the air filtration industry, such as the Swedish-based firm Nederman, are concentrating on solutions to safely handle the material as it travels through the facility’s air filtration system, rather than simply removing it from the air in the workspace.

Anyone who owns, operates, or works in an industrial facility knows the importance of removing harmful dust from the air. However, as production techniques and materials modernize at an alarmingly swift pace, the combustibility of the dust created is now a major concern. Increasingly, leaders in the air filtration industry, such as the Swedish-based firm Nederman, are concentrating on solutions to safely handle the material as it travels through the facility’s air filtration system, rather than simply removing it from the air in the workspace.

As new composites and alloys are developed and enter the production process, Nederman is committed to finding and developing solutions to protect workers from the dangers of smoke, fume, and other air filtration issues, including combustible dust.

“When I first started at Nederman 21 years ago, ‘what types of combustible dust is your operation dealing with?’ really wasn’t a question that we had to ask.” says Jeff Converse, solution sales manager of Nederman’s metal fabricating segment. “It has just changed so much. I’m even amazed at what types of dust are combustible from organic dust materials.”

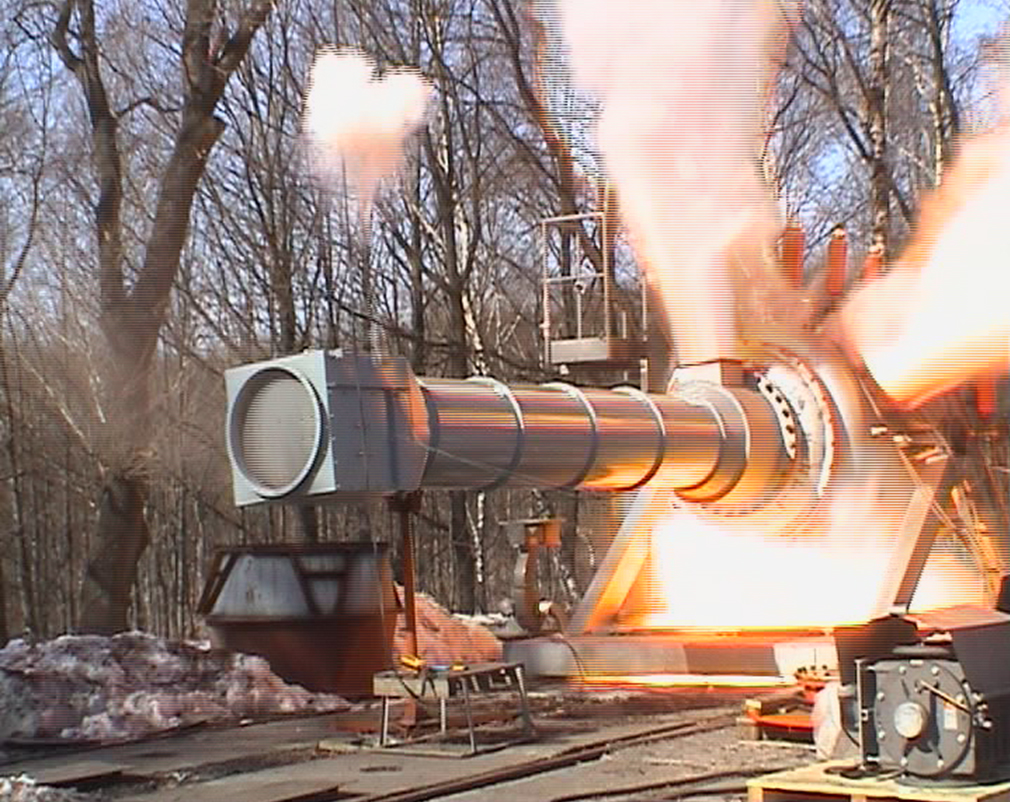

Recognizing combustible dust as a major problem, Nederman researchers spent close to two years developing a state-of-the-art line of equipment, the Explosion Isolation Flap Valve CARZ-N, or simply CARZ-N for short. In case of an explosion inside the dust collector, the CARZ-N flap valve system is designed to prevent the worst-case scenario – an explosion sending fire or shrapnel from the filter system back into the facility.

“Part of solving the combustible dust problem is making sure the collector itself is protected,” explains Daniel Rousseau, technical director of cartridges & collectors for Nederman.

“Typically, on our end, if there is going to be an explosion or something happening, it’s going to be inside the dust collector,” Rousseau adds. “If that occurs, you need to make sure that your ducting that’s connected from all your machines to the dust collector, that any explosion or fireball gets stopped inside the ducting and does not go inside the plant.” The CARZ-N valve works similarly to a clothes dryer vent. When you are drying clothes, the valve remains open as air flows through, and closes when the dryer is off – keeping animals and dust from coming back inside the home.

The CARZ-N valve is comparable, allowing air to go through flap as normal, but should an explosion occur, “the pressure from the fireball and the pressure wave from any kind of explosion will actually shut and stop any fire from coming back inside the building,” says Rousseau.

The CARZ-N valve is comparable, allowing air to go through flap as normal, but should an explosion occur, “the pressure from the fireball and the pressure wave from any kind of explosion will actually shut and stop any fire from coming back inside the building,” says Rousseau.

Additionally, the CARZ-N valve system not only ensures a safer working environment but can also lead to greater efficiency, cost-effectiveness, and improved morale, according to Converse.

“Once it’s in there it gives the whole plant a feeling of relief just to know that ‘hey if something happens outside, we know we’re protected inside and nothing’s going to happen. We’re not going to hear about these horror stories about buildings being leveled,'” says Converse. “Also, it has helped companies insurance-wise. Once the insurance company sees that they have implemented some things to make the workplace safer, they are finding better rates.”

“Once it’s in there it gives the whole plant a feeling of relief just to know that ‘hey if something happens outside, we know we’re protected inside and nothing’s going to happen. We’re not going to hear about these horror stories about buildings being leveled,'” says Converse. “Also, it has helped companies insurance-wise. Once the insurance company sees that they have implemented some things to make the workplace safer, they are finding better rates.”

As manufacturing industry sectors continue to grow, Converse and Rousseau say educating customers on new forms of combustible dust is a major part of their work. Current manufacturing trends using composites, metal alloys, and additive manufacturing – commonly known as 3D printing – are creating unique air filtration challenges in those sectors that will eventually lead to new techniques.

“Composite dust is highly combustible and explosive, and that is also a big learning curve for those customers,” Rousseau says. “When you think about plastic if you heat it or put a flame on it, it will melt, but the fine dust that is generated during manufacturing is also highly combustible just like wood dust is.

“Composite dust is highly combustible and explosive, and that is also a big learning curve for those customers,” Rousseau says. “When you think about plastic if you heat it or put a flame on it, it will melt, but the fine dust that is generated during manufacturing is also highly combustible just like wood dust is.

“These metal alloys are probably some of the most combustible dust out there and now you’re adding heat and other technology to melt these things together,” Rousseau adds. “I haven’t fully seen where that technology is going, but there are definitely going to be a lot more changes, and a lot more technology development for that specific market.”

Regardless of the material in use or the manufacturing process employed, combustible dust is now a focus of every conversation Nederman has with a new customer or an existing customer looking to expand its operation. Educating the customer on what they can and can’t do, navigating local, state, and federal regulations, complying with OSHA regulations, and finding cost-effective solutions to combustible dust issues are the primary points of discussion on any new project.

“We have to play by the rules and play by the book, and there are a lot of people out there that just don’t know what you can and can’t do or even what is combustible. I’m working with engineers in the marketplace that have no idea that wood dust is even combustible,” Converse says. “That’s a big challenge for us, trying to educate people on the standards while educating them on how our air filtration equipment can ensure a safe work environment.

“It’s just so much more recognized now and it just has to be the first question that you ask, because none of us at Nederman want to be sitting at home at night and here about an explosion at a plant or at a school and have to deal with anything like that,” he adds. “It’s something that we are very cognizant of, it is the first question that we ask, and something that we deal with accordingly.”