Stretch forming is a unique process where material such as steel, stainless steel, aluminum, or even titanium is stretched beyond its yield point and simultaneously wrapped around net shaped dies. Forming sheet or extruded material using this method essentially shifts the neutral axes of a part to the perimeter of the die resulting in a smooth, wrinkle-free contour that closely retains the shape of the die, improves the mechanical properties, and eliminates many post process steps used to attain dimensional accuracy.

Initially developed as an efficient means to produce components with complex curved profiles in the aircraft industry, stretch forming is now widely used for similar components in automotive, aerospace, construction, rail, and rocketry.

“As part producers seek to expand their capabilities, many have approached us with new stretch forming applications. Combining modern CNC technology with our precise digital die mapping technology and historically robust machine structure provides for the finely tuned automated motion control necessary to maintain constant strain in the part throughout the cycle, all resulting in industry leading dimensional stability.” says Dave Gardner, Senior Mechanical Engineer at Erie Press Systems, a company that manufactures custom-engineered hydraulic presses for applications including metal forming, stretch forming, composite compression molding presses, cold extrusion, and forging. Park Ohio acquired Erie Press Systems in 2020 and is now a part of Ajax-CECO-Erie Press (ACE), the largest forging equipment supplier in North America, with over a century of experience in custom designing and building presses and forming machines.

Manufacturers that are unfamiliar with stretch forming as well as those with special requirements often require guidance to select equipment that meets their specific needs.

Drawing on Erie Press’s decades of experience in aerospace applications and ACE’s century of fabricating machinery, Gardner covers the basics of stretch forming and provides tips for selecting equipment that can help to maximize product quality, reliability, and productivity.

Stretch Forming Basics

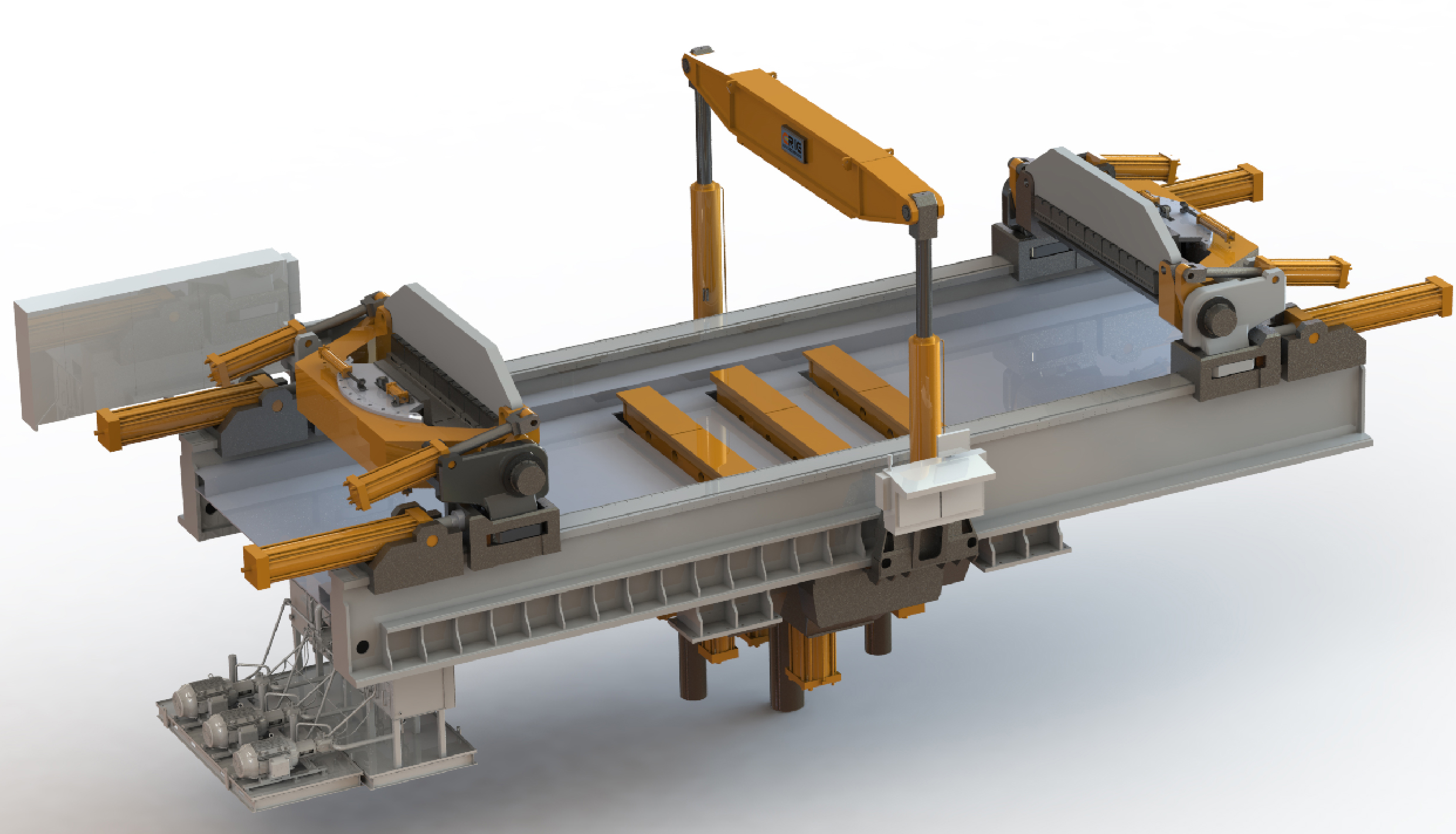

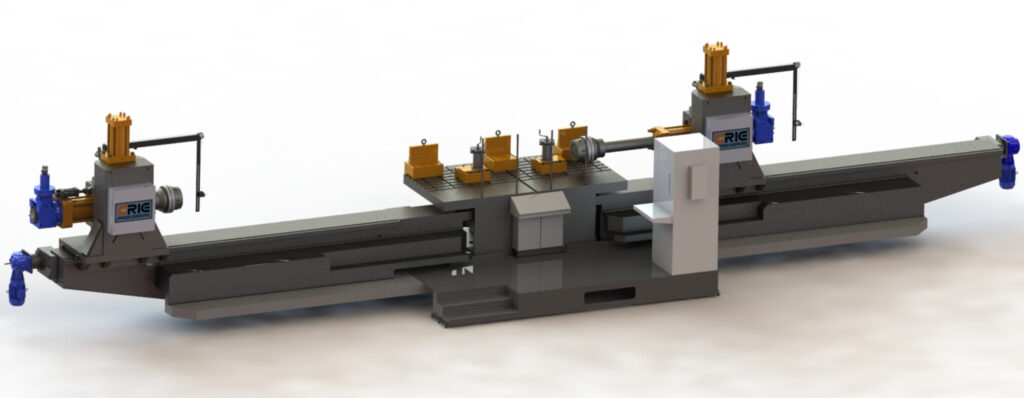

According to Gardner, stretch forming machines may be classified into three primary design types, depending on the client’s intended production requirements. Sheet stretch forming machines are used to produce complex curved sheet metal parts such as exterior panels and leading edges on aircraft, high-speed trains, RVs, buses, and commercial rockets. Extrusion stretch forming machines are used to produce extruded structural components with complex cross sections and curved profiles such as stringers and support beams for aircraft, skeletal components for locomotives, buses, transportation structures, and various curved shapes used in the elevator and architectural (building) industry. High-speed, high-volume stretch forming machines are generally reserved for forming extrusions in automotive or other high production applications.

Each design type classification can be further broken down into a series of machines with specialized features that are better suited for producing specific types of parts.

“Due to the wide range of features and options that are available, we work with our clients to develop the technical details of a machine that will fully meet their unique production requirements,” says Gardner.

Stretch forming offers numerous advantages, including the ability to accurately form complex shapes while maintaining the part’s total volume. Once the component is stretched into the yield state, less force is required to wrap the part around the die than with other forming methods. Part cost is substantially reduced by the ability to form accurate and repeatable components with little wasted material and, in most cases, a scuff-free quality finish that doesn’t require dimensional or cosmetic improvement. Additionally, the process induces work hardening in many materials, which increases strength while reducing internal residual stress and spring back as compared to conventional bending operations.

From Gardner’s decades of machine design experience in various applications, he advises that clients consider the purchase of stretch forming machines with these important qualities:

Structural integrity and longevity

Stretch forming is not a high impact process, but forces involved can be over 3,000 tons in some aerospace applications. High-quality stretch forming machines with very precise motion control and the ability to digitally map the contour of the die with respect to the forming axes will form the part with nearly constant strain throughout the process and create very precise, consistent parts for many decades. Consequently, it is important to select a machine with these features to extend its accuracy, longevity, and reliability.

“Machines with inherent compliance (deflections) or off-line programming systems that only approximate the die profile in respect to the axes positioning system cannot assure constant strain in the process, often leading to inaccurate or non-repeatable part production,” says Gardner. “Lighter construction machines with weak or bolt together frames are simply not designed to hold up to extended use.”

Selecting a stretch forming machine with a robust, heavy frame, and properly designed connection points to the die table is therefore essential to ensure its accuracy and reliability for decades. ACE has systematically improved the structural integrity of its core design since acquiring the legendary Hufford and Sheridan Grey design rights in 2001, many of which have been in production since the 1940’s.

For sheet stretch forming equipment, it is particularly important to maintain a rigid structural frame to ensure accurate, consistent part creation.

“If you want to form accurate parts with a high degree of repeatability, you need to minimize compliance, that is deflection, from the machine structure,” says Gardner.

However, this is an issue in machines with “optimized” construction which tend to allow greater deflection during the stretch forming process. ACE’s robust structure is complemented by stiff connection points between moving machine members, which provide a system that reduces the total deflection throughout the forming cycle. The result is a process that is more precise and accurate, with predictable part quality.

Superior control

Stretch forming operates within the material conditions between the yield point and its ultimate strength. Commonly, high temper materials have a narrow operating band to form above the yield point and do not exceed its ultimate strength. Precise motion and force control of the process is a vital consideration in machine selection if you expect to consistently achieve repeatable part production.

According to Gardner, “A perfectly envisioned stretch forming cycle would include the ability for the machine to monitor the strain rate within the part as force increases along its axis, capture the strain when the part transitions slightly above the yield point of the material, and form the part with nearly constant strain throughout the forming cycle.”

Practical limitations that affect a forming cycle include variations in the materials cross section, variations in the mechanical properties within the part (or batch of parts), dynamic deflections in the machine structure, discrepancy in the machines axes controls to properly adjust for the contour of the die, and even the ability to program a precise profile path that duplicates the contour of the die.

He points out that attaining finer control of the stretch forming process is imperative to automated part production and achieves two important aims.

“First, it regulates the forming process so you can operate within a tighter band between the yield strength and the ultimate strength of the material to reduce part breakage,” says Gardner. “Secondly, it allows the machine to very accurately approximate constant strain within the part by comparing its measure length to the applied axial force once it transitions into the yield state. In this way, the yield stress in the part and the length of the part remains consistent through the forming process.”

Control system upgrades

Control system upgrades

Most of the sophistication in today’s stretch forming machines involves control system improvements for axes positioning systems, hydraulic force control, part programming, and ease of use for operators.

In ACE’s stretch forming presses, for instance, the OEM simplifies operation by incorporating touchscreen, menu-based Human Machine Interfaces (HMIs) to automate the forming cycle. Traditional stretch forming machines which employ manual controls require highly specialized operators that make intuitive adjustments during the cycle to achieve acceptable results.

Utilization of the HMI approach facilitates automated production, reliability, and consistency while greatly reducing broken or out-of-tolerance parts. Modern, high quality control systems for stretch forming machines include automatic yield point detection systems, the ability to automate the programming process, monitor the forming process, contain machine diagnostic protocols, and have advanced safety systems for operator protection.

Along with the standard features listed above, ACE offers a two-pronged approach to provide forming predictability with integrated part programming. Standard supply includes an easy-to-use and highly accurate, proprietary automated part programming system that utilizes the machine axes to digitally map the profile and synchronize axes positioning during a simulated forming cycle with the die installed on the machine. Additionally, off-line programming software is offered that contains modules for FEA-based forming feasibility studies, spring back prediction to aid die design, machine collision detection, and that is capable for two-way communication with the machine for off-line part programming.

“Traditionally, spring back is a problem when forming tempered parts. Our software predicts these reactions based on actual material properties at the time of forming. Spring back values are used to make virtual die geometry adjustments and the feasibility study is duplicated until simulations indicate accurate parts are produced. Our beta version is provided with the latest machine we sold, which is a sheet stretch forming press,” says Gardner.

Gardner explains the need for die customization in the extrusion stretch forming machine process.

“Certain types of alloyed material, particularly some grades of extruded aluminum, will age harden at room temperature in a relatively short amount of time. Processing these parts directly from the annealing furnace, before age hardening occurs, will improve the consistency of the formed profile. Age hardening after they have been formed usually will not affect the dimensional stability of a properly racked part.” says Gardner.

Forming aluminum closer to the ‘0’ temper condition (or annealed condition) results in a consistent process that will more closely adhere to the net shape of the die, according to Gardner.

“A lot of our clients will form tempered aluminum extrusions, say up to a T4 temper condition, but tempered material retains some amount of residual stress during the forming process and the die must be designed to accommodate some degree of spring back. So, you will have some spring back when forming tempered material, but certainly a lot less than witnessed in normal bending operations,” says Gardner.

“A lot of our clients will form tempered aluminum extrusions, say up to a T4 temper condition, but tempered material retains some amount of residual stress during the forming process and the die must be designed to accommodate some degree of spring back. So, you will have some spring back when forming tempered material, but certainly a lot less than witnessed in normal bending operations,” says Gardner.

Options to speed production

Manufacturers often seek options to speed the stretch forming process. However, expediting the process generally involves part or tool handling, not part forming, according to Gardner.

“If the part forming process is too fast, particularly on sheet material, Lüder lines [surface markings] occur on the surface from unwanted elastic flow of the material caused by improper strain control. These normally will have little effect on the profile of the sheet but are an undesirable visual effect, so you can only form as fast as the material will allow,” says Gardner.

To facilitate faster, higher rate production, ACE offers options for automated part loading/unloading and improved tool change systems in their stretch forming machines.

For example, extrusion stretch forming machines may use fixed dies rigidly mounted to the die table and jaw inserts that are manufactured specifically to grip the unique shape of the extrusion being formed. Machines furnished with the standard balanced lifting brackets allow complete tooling changes in around 30 minutes by experienced operators. Automating the process will reduce the complete change out times to around 5 – 10 minutes, depending on the machine size.

Adding to the challenge of selecting options, certain manufacturers may need to frequently perform complete tooling changes due to short production runs and may benefit significantly from automating the tool change system. Other manufacturers have very high production quantities of the same part and may receive greater benefit from automating the part loading systems.

“To speed production for both short and long production run manufacturers, we can accommodate complete or partial automation for tooling or part changing systems. Generally, we expect the lost time of these non-production related events to decrease by 60–75% when compared to standard, non-automated processes, depending on the unique requirements of each specific application.” says Gardner.

Whether manufacturers are new to stretch forming or seasoned industry veterans that simply want to extend their capabilities, thoughtful selection of a machine specifically engineered to satisfy their unique requirements will result in the most robust, reliable, and cost-effective solution for expanding their capabilities and improving their processes.