ERP: The Financial Backbone of the Organization

ERP systems were originally designed to be the transactional backbone of the enterprise. As such, they focused heavily on the financial aspect of the business. Many systems started out as a set of financial applications combined with a light level of inventory management and sales order processing to help capture transactions at their source. Yet even today, many of the ERP systems designed to address multiple vertical industries are focused more on the financial management of the business and less on the activities, such as manufacturing, that drive those numbers. As a “system of record” for the financial health and management of the organization, ERP is hard to beat. But, ERP often falls short when it comes to managing the activities behind those transactions.

Production scheduling is one of the most common shortcomings. Because of their origins as financial systems of record, many traditional ERP companies often take a transactional, materials-based approach to production scheduling. When an order is entered into the system, the manufacturing module (usually some form of Material Resource Planning or MRP system) looks at the materials and components on hand. Available inventory is allocated. Any additional inventory or components needed are either ordered or scheduled for production. Each of these events then creates a financial transaction that flows through the system all the way to the general ledger.

Though MRP systems were a step in the right direction, they had serious limitations. As the name suggests, these applications were focused on materials with little thought as to whether the facility had the available capacity to produce a product let alone whether it would be profitable to do so. Furthermore, they were plant-centric with few supply chain capabilities.

Finite capacity scheduling (FCS) was quickly introduced as a point solution to make up for the scheduling limitations of MRP. With FCS, the production planner could at least take into account the capacity of the plant even if they had limited ability to incorporate available capacity across the supply chain. But even though these systems could tell the planner what the factory could produce (capable to promise), they still didn’t provide any insight into whether the order would be profitable (profitable to promise).

Advanced Planning and Scheduling (APS) took off in the 1990s as computing power made more complex calculations possible. Now, the manufacturer could look at both material requirements and capacity to optimize their production schedule. Higher-end ERP vendors started to add APS applications to their product suites. But APS also came with limitations in that it was designed with push-based manufacturing in mind and focused on optimizing individual aspects within the four walls of the manufacturing plant and not across the entire supply chain.

Advanced Planning and Scheduling (APS) took off in the 1990s as computing power made more complex calculations possible. Now, the manufacturer could look at both material requirements and capacity to optimize their production schedule. Higher-end ERP vendors started to add APS applications to their product suites. But APS also came with limitations in that it was designed with push-based manufacturing in mind and focused on optimizing individual aspects within the four walls of the manufacturing plant and not across the entire supply chain.

We can’t necessarily blame the developers of these solutions for their inability to facilitate synchronized single- or multi-enterprise supply chain planning, scheduling, and execution. The technologies needed to foster collaboration were just not available when these applications were in their heyday. After all, it’s hard to do cross-supply chain planning when you’re sharing data over a dial-up modem.

This brings us to where we are today. Computing power has grown exponentially until the power of the smartphone inside almost every factory worker’s pocket is equivalent to the power NASA used to land a man on the moon. Furthermore, SaaS (software-as-a-service) delivery models and the web have redefined the scope of applications and put advanced functionality within reach of even modest budgets.

This transactional, materials-based approach doesn’t work well with the reality that is modern manufacturing where available capacity is just as critical as material availability and when demand changes or events require schedule adjustments at a moment’s notice.

Back to Spreadsheets?

Today, these ERP add-on systems fall short because the primary transactional design of the ERP software still takes precedence. Often, this transactional design leads these solutions to be too complicated or not agile enough for the modern manufacturing environment. Worse, they don’t allow for the manufacturer to evolve and take advantage of modern manufacturing philosophies like Lean Manufacturing, Theory of Constraints, and Demand-Driven/Pull Manufacturing.

To compensate, many production managers and planners have dismissed these add-on solutions and resorted to working with spreadsheets. This approach also quickly becomes unworkable as multiple spreadsheets mean different people are working from different versions of the truth, all of which contain outdated data to some degree. Visibility into the entire supply chain isn’t even within the realm of possibility, leaving decision makers in the dark and putting the organization at a distinct disadvantage compared to their more agile competitors.

The Manufacturing System of Record

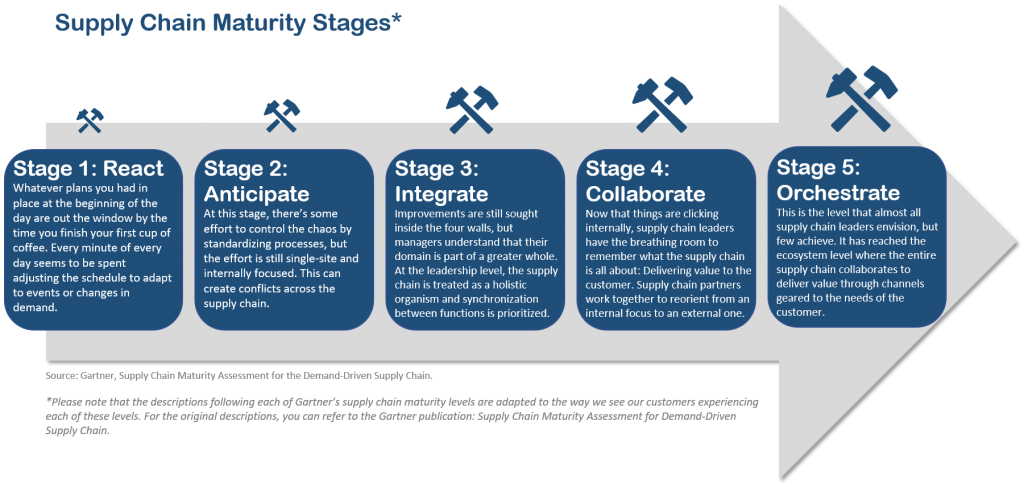

Manufacturing is all about synchronizing supply and demand across operations and the supply chain in a way that most profitably allows you to meet your customers’ objectives. An organization’s stage of supply chain maturity reflects their ability to accomplish this goal.

Gartner research describes an organization’s Supply Chain Planning maturity in five phases. In phases one and two, manufacturers rely on spreadsheets and ERP attachments. In phase three, manufacturers take a giant leap forward with a System of Record. Phases four and five go even further, with ever-more sophisticated algorithmic planning and innovation garnered through the vast amount of curated data available through the Industrial Internet of Things (IIoT).

To get to phase four and five, however, an organization must achieve maturity in phase three. This is best accomplished by optimizing and aligning their manufacturing operations and the extended supply chain through a Manufacturing System of Record that is layered on top of the ERP system. This provides the agility and “single version of the truth” needed by today’s manufacturers/.

Layered Technology Approach

Layered Technology Approach

Rather than rip-and-replace existing systems, a layered technology approach allows you to extend the value of your transactional and legacy systems by layering on modern manufacturing solutions. These modern, web-enabled solutions were developed to be highly flexible and scalable to adapt to how you work today – and how you may choose to work in the future.

Within the context of the supply chain maturity stages, a layered technology approach allows manufacturers to progress all the way to stage five at their own pace. The first step for many manufacturers is to address their production issues by layering on demand-driven or pull-based Manufacturing System of Record on top of their existing ERP implementation. The Manufacturing System of Record synchronizes planning, scheduling and execution across their manufacturing operations and extended supply chain based, on real-time demand. In doing so, they achieve supply chain maturity stage three and beyond.

Additional components can then be layered on to further maturity, allowing manufacturers to leverage the IIoT and Big Data by aggregating actionable data from disparate sources, such as shop floor devices and business applications, then analyzing and serving it up in real-time via customized dashboards reflecting status, metrics, alert notices, and more.

Get to Work Faster; Get Results Faster

Ever come home from the hardware store with a new tool? I bet you couldn’t wait to use it. Manufacturers understandably feel the same way when they’ve invested in new technologies for their business. The problem with ERP solutions is that after you spend six figures (or more) with the vendor, you have to wait a year (or more) before the implementation is far enough along to add any value. ERP add-ons like APS and FCS aren’t typically even included in phase one of most implementations, so your ROI is delayed even longer.

Another advantage of new, web-enabled and more agile layered technologies is that they can be implemented faster so you experience performance improvements faster. And, as enterprise class solutions, they have all the capabilities you would expect – and can be easily configured to your unique environment. You keep using your current ERP transaction system of record just as you do today, but you’ve gained a true manufacturing system of record that works the way you do.

Gaining real value from the age of manufacturing digitization, starts at the core – where and how you deliver value to your customers. Replacing manual processes (or technologies that don’t allow you to work the way you need to) with smart, adaptive technology that delivers value to both you, and your customers, is worth exploring.

About Synchrono®

The Synchrono Demand-Driven Manufacturing Platform digitizes, synchronizes, and visualizes the enterprise and extended supply chain, bringing the Internet of Things to life. Combining synchronized planning, scheduling and execution with automated inventory replenishment, manufacturing operations, self-service visualizations and more, Synchrono synchronizes people, processes, machines, materials and data orchestrating flow and enabling real-time visibility.