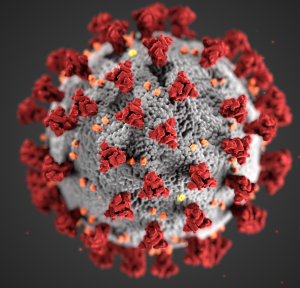

Before I began writing for Industrial Machinery Digest, I worked for a decade in the medical diagnostic industry. It was primarily second or third shift positions, allowing me to pursue aspirations of journalism during normal business hours. I had worked my way up from a simple specimen preparation technician, who processes and handles specimens, to a lab assistant running the tests that impacted patients’ daily lives. During that time, there was never any outbreak as devastating as the novel coronavirus, COVID-19.

At the time of this writing, no guidelines have been officially put in place to assist manufacturing and fabricating businesses. This crisis will be turning to the manufacturing sector for solutions. Automakers are already evaluating efforts to produce ventilators, and other equipment in response to the pandemic. General Motors, for example, announced that it would be working with Seattle’s Ventec Life Systems to support the increased production of respiratory care products.

A recent National Association of Manufacturers survey indicated that 78.3 percent of manufacturers anticipate financial impact. Over half surveyed were anticipating an impact in operations, and more than 35 percent were already facing supply disruptions. NAM has laid out policy actions as a response to the COVID-19 pandemic. These guidelines have been presented to Congress and other federal agencies to protect, and further underline the importance manufacturers will be in the days ahead.

A recent National Association of Manufacturers survey indicated that 78.3 percent of manufacturers anticipate financial impact. Over half surveyed were anticipating an impact in operations, and more than 35 percent were already facing supply disruptions. NAM has laid out policy actions as a response to the COVID-19 pandemic. These guidelines have been presented to Congress and other federal agencies to protect, and further underline the importance manufacturers will be in the days ahead.

“Manufacturers have a greater purpose than profits,” says Mike Lamach, NAM Board Chair and Chairman and CEO of Trane Technologies plc. “We are also about protecting our people, and our communities.”

First and foremost, NAM’s COVID-19 Policy Action Plan Recommendations ask Congress to recognize manufacturers’ critical role in response to the pandemic with, at least, $1.4 trillion in interest-free loans for a federal Manufacturing Resiliency Fund. To ensure the supply of products, manufacturers are to be deemed essential businesses and protected as such. NAM is also trying to protect manufacturing business owners from insolvency with efforts to have the IRS delay all scheduled tax payments for 90 days.

It should be noted that the U.S. Small Business Administration is currently working with state governments to provide low interest loans for businesses suffering from loss of revenue due to COVID-19. The Economic Injury Disaster Loan Program can provide working capital of up to $2 million to help maintain standard operations. The SBA has also provided guidance backed by the CDC on how to avoid stigma and workplace discrimination that may be associated with virus.

In terms of providing a safe workplace, NAM guidelines also call for clear CDC guidance for cleaning and disinfecting plant and production facilities. With clear rules in place, manufacturers can make more confident decisions, to ensure the safety of workers, even if that requires full plant shutdowns due to community quarantine.

In terms of providing a safe workplace, NAM guidelines also call for clear CDC guidance for cleaning and disinfecting plant and production facilities. With clear rules in place, manufacturers can make more confident decisions, to ensure the safety of workers, even if that requires full plant shutdowns due to community quarantine.

“Already, manufacturers are grappling with disruptions to their businesses due to the COVID-19 outbreak, with many anticipating financial and operational consequences. The federal government can take steps to further equip manufacturers to deal with COVID-19 by implementing the NAM’s ‘COVID-19 Policy Action Plan Recommendations,’” said NAM President and CEO Jay Timmons. “Across the country, manufacturers are stepping up to keep their employees and their communities safe and healthy, and working closely with elected officials, we can ensure the resilience not only of our companies but also our country.”

These measures and others included in NAM’s Policy Action Plan could even be used to allow for further investment in upgrading and improving our nation’s transportation, water, energy, and digital infrastructure systems by supporting NAM’s “Building to Win” strategy.

The Manufacturing Landscape Going Forward

It is far too early to act like we are on the road to recovery. Currently, there are more than 188,647 confirmed cases in the United States, with many sources saying the peak for this viral epidemic being now mid-May (Editor’s Note: When the article was written, the number was originally at a rough 30,000 cases. Before we went to press, we updated it to 60,000. After we sent files to the printer, the cases had already risen to more than 80,000. We have updated the number of confirmed cases as reported on April 1, 2020 at 7:00AM CST).

This is the time for businesses to work smarter not harder. The manufacturing sector has been facing a labor shortage and has already made efforts in closing the ever-growing skills gap. Automation solutions, such as collaborative robots, could become even more important to meet production demands. Other technologies including artificial intelligence and remote assistance applications with Artificial Reality (AR) support could allow businesses to connect more easily for training and service of key production machinery.

None of that will matter, however, if we do not all do our part in eliminating the spread of this pandemic. How we respond to this crisis determines how fast we can truly recover. It is imperative that we all take measures to ensure the health and safety of our coworkers, friends, family, and ourselves.

About National Association of Manufacturers

The National Association of Manufacturers (NAM) works for the success of the more than 12.8 million men and women who make things in America. Representing 14,000 member companies—from small businesses to global leaders—in every industrial sector, the National Association of Manufacturers (NAM) is the nation’s most effective resource and most influential advocate for the values for manufacturers across the country.