Bad inventory management can cost your company tremendous amounts of time, money and, ultimately, its chances of success. It can heavily impact any business’ organizational performance, leaving it with lackluster profit margins and elevated overhead expenses as a result.

No business is exempt from the effects of poor inventory management. Even multinational corporations like Walmart know first-hand just how much a disorganized inventory can cost them. The aforementioned grocery chain giant lost a whopping $3 billion to poor inventory control back in 2013, and suffered regular stock-outs for months after the fact.

If this is how improper inventory practices and protocols affect massive corporations, it might be easy for you to imagine how the same mistakes could affect your business. These mistakes have led to many manufacturers closing their doors, and have left others struggling amid seas of debt and organizational challenges.

Big Risks for Manufacturing Firms

The risk of losing your business is reason enough to accept that bad inventory management is worth avoiding. This sort of fundamental problem with your firm can negatively affect your bottom lines, and can even hold your company back from its long-term growth goals.

The risk of losing your business is reason enough to accept that bad inventory management is worth avoiding. This sort of fundamental problem with your firm can negatively affect your bottom lines, and can even hold your company back from its long-term growth goals.

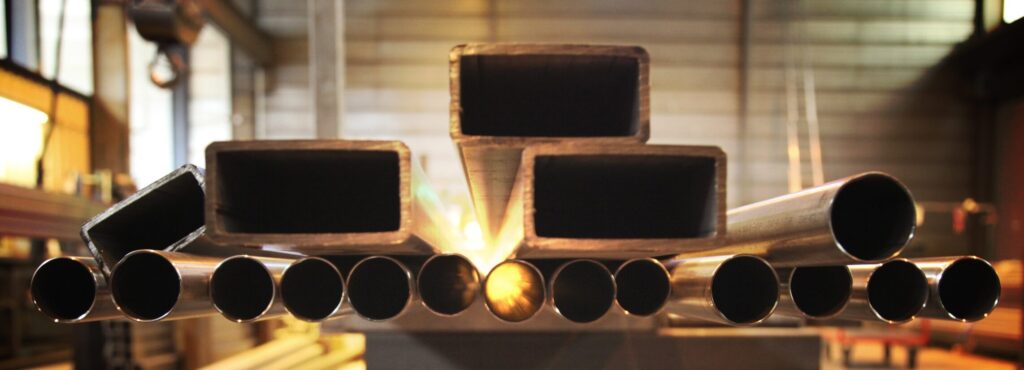

Manufacturing and fabrication firms can be particularly hard-hit too. They rely on a structured inventory of materials and goods to maintain their strict organizational performance.

Studies have conclusively shown that firms that don’t properly manage their inventories aren’t equipped to avoid the costs of evolving production rates, overtime, unnecessary costs of sales, sub-contracting, and back-order penalties during times of high demand. This can lead to problems with cash flow and slim profit margins, as well as organizational challenges like a lack of alignment, accountability, and trust in managerial staff.

Here’s how to know if your inventory is being managed poorly, and what you can do to rectify it.

The Signs of Substandard Inventory Management

There are dozens of telltale signs to look for that indicate bad inventory management within your business. These signs will vary from industry to industry, but there are several parallels between them.

Here are the most obvious signs of poor inventory control:

- Frequent stock-outs;

- Consistently high inventory costs;

- Low or decreasing inventory turnover rates;

- Large amounts of obsolete inventory;

- High working capital rates;

- Excessive material and product storage costs;

- Errors in data entry for spreadsheets;

- Shipping incorrect items to customers and clients;

- A consistent loss of customers; and

- Imbalanced lead times.

There are a number of convergent factors that come together to produce these deleterious symptoms. However, most if not all of them connect to the way you manage your business’ inventory. This means that with a few strategic adjustments, you can remedy these issues and get your manufacturing firm back on the path to success.

The Causes of Bad Inventory Management

There could ultimately be hundreds of different reasons why your inventory is being mismanaged. These are some of the most common and probable reasons why your inventory control and the company’s organizational performance is suffering.

- Spreadsheets

Most small to medium-sized businesses (SMBs) use Microsoft Excel spreadsheets to manage their inventory. Spreadsheets tend to start out working well for smaller businesses, but their use can quickly lead to the development of devastating issues. This is particularly true for businesses that are growing rapidly.

Stephen Powell of Tuck Business School at Dartmouth College conducted a study of errors in 25 sample spreadsheets to demonstrate this point. He found that 15 of the spreadsheets contained errors. The total number of errors clocked in at a concerning 117.

Around 40% of those errors discovered had minimal impacts on the businesses studied. However, according to the researchers, 7 of them led to significant losses of between $4 million and $110 million in revenues.

- Manual Stocktaking and Inventory Tracking

Manual inventory tracking and stocktaking are perfectly functional for smaller businesses, but can become time-consuming and prone to errors as your company expands. If you use these processes to manage a medium or large business’ inventory, you’ll always fall one step behind your true inventory levels. This will cause ongoing issues with ordering.

Say, for example, your assistant manager skips an essential step in the stocktaking process and fails to update the stock levels. Because of the error, you will likely order too much or too little, and end up with obsolete stock (or stock-outs) on your hands.

- Large Inventories

Hefty inventory volumes can create more managerial challenges, but they can also negatively impact your profits. A large percentage of businesses have between 20% and 40% of their working capital tied to their inventories.

It may be difficult to reduce your firm’s inventory, but it’s important to do so if you want to improve your inventory management and overall organizational performance.

- Substandard Forecasting

There are two scenarios that can stem from your business not having access to accurate reports regarding customer habits, best-selling products, sales trends, and other vital data. One, you may order too many raw materials and deal with the issues of an overstocked inventory. Two, you could under-order and experience stock-outs as a result. The latter scenario could lose you precious customers.

Once you insist on gathering and working with accurate reports, you’ll be able to better predict your customers’ future behaviors. This means you can order raw materials to manufacture products that meet customers’ demands without exceeding your firm’s budget.

Accurate forecasting not only helps you stay within your budget, it can also determine whether you’ll need additional funding to facilitate growth. This is where a tool like a business loan calculator can come in handy, as it assists in determining the true costs of a loan. Using this data, you can ascertain how feasible your growth strategy is, and by how much you can afford to scale up your inventory.

Solutions for Bad Inventory Management

There are a myriad of possible causes for poor inventory management, and you may already have a clear idea of why your business is struggling. That said, let’s move on to workable solutions.

There are a myriad of possible causes for poor inventory management, and you may already have a clear idea of why your business is struggling. That said, let’s move on to workable solutions.

The first solution you can implement for your inventory woes is to read up on the best inventory management practices. You can more effectively manage your inventory and warehouse, and train your staff to do the same once you have the knowledge and skills needed for the job.

Second, you can investigate implementing a cloud-based inventory management program. Reliable programs offer tools and metrics like:

- Accurate and up-to-date forecasting;

- Automated data entry; and

- Real-time inventory tracking.

All of these can help you develop a more effective strategy for managing your manufacturing business’ inventory.

Cloud-based inventory management has the power to improve your firm’s customer service and stock visibility. At the same time, it offers convenient and automated inventory updates that can make your management chores simpler.

Cloud solutions offer superior safety and security, as all of your inventory data is encrypted and stored on secure virtual servers. Plus, they boast real-time operational visibility of order execution, selling processes, and dispatch of goods to enhance your organizational capacities.

Streamlining Inventory Management For Success

Bad inventory management can eat away at your company’s profits and organizational structure while driving up operational costs.

Consider implementing cloud-based inventory management software and researching best management practices. This will give your company an organizational performance boost.