Harnessing the power and capability of robust robotic automation for greater productivity gains is the ultimate goal of any robot installation. Unfortunately, constant market pressures and customer demands have a way of pulling key personnel in a myriad of directions, pushing a keen focus on return on investment (ROI) to the wayside.

While the presence of robots and other advanced technologies alone may be enough to deliver transformative change to an organization, that does not necessarily mean a company has reached its full potential for achieving ROI. To regroup and circle back towards a path of optimal productivity, there are five key steps manufacturers should consider taking.

Execute a Strategic Plan

Execute a Strategic Plan

From employee buy-in to robot redeployment and everything in between, manufacturers should utilize a thorough agenda with best practices and achievable action steps to facilitate smooth installation and peak performance for capital equipment. While robots today are extremely reliable, each should have a well-maintained life cycle that includes:

Proper Installation

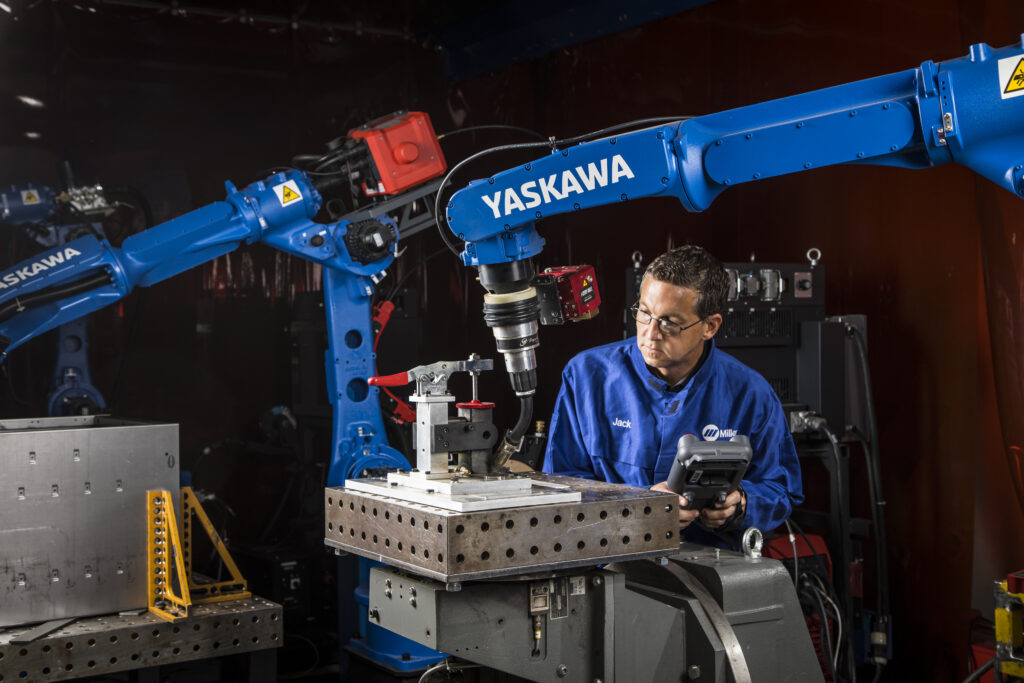

Crucial for the robot, as well as any peripheral equipment, it is strongly advised to partner with experts from a knowledgeable robot supplier or integrator during the initial setup process. Many company leaders are finding it helpful to hire a “workcell champion” before robot integration occurs, as this individual takes on the responsibility of ensuring full utilization and success of the robotic system.

Process Optimization

It is important to remember that a robot is part of a bigger picture. For this reason, it is vital to monitor the complete functionality of the entire application. Being proactive here by making appropriate adjustments to parts, fixturing, peripheral tools, programming, etc. can help prevent unnecessary asset deterioration and bolster production where throughput, cycle time and scrap are involved.

Regular Maintenance

To prevent premature robot and equipment failures, performing regularly scheduled system maintenance (i.e, grease analysis, torque analysis, backlash testing, etc.) and safety audits is suggested every 6,000 servo-hours. Many manufacturers choose to implement “holiday shutdowns” or “factory fortnights” – scheduled breaks where company leaders close production facilities for a brief period of time to address robot maintenance and other process improvement initiatives. Regardless of the timing for these critical checks, it is important to deploy a smart inventory strategy for replacement parts such as controller CPU batteries, air filters, gasket covers, cables, grease and more.

Continuous Improvement

Continuous Improvement

A plethora of knowledge can be gained by performing regular maintenance, and it is always wise for manufacturers to take this information and carefully analyze it, responding in an appropriate and timely manner as needed.

Calculated Redeployment, Rebuilding Or Replacement

With regular maintenance, most robots perform 15+ years. However, there will come a time when production needs change, or a robot will need upgraded or replaced. Having an existing relationship with a robot supplier or integrator at this stage can go a long way to answering any questions that arise.

While there is not a one-size-fits-all approach when it comes to strategic plan execution, manufacturers that follow these basic steps for implementing and maintaining a robot should be well on their way to top robot efficiency for maximum ROI.

Focus on Equipment Performance

Integrating more affordable, robust and easy-to-use robots with existing operations can help manufacturers tackle tough dilemmas for a wide range of tasks like assembly, inspection, machine tending, packaging, palletizing and more. While the addition of robotic technology along a production line can provide “quick wins” for greater productivity and lower operational costs, it is still important for manufacturers to strive for 100 percent effectiveness with each piece of machinery. For this reason – regardless of industry – a greater focus should be placed on Overall Equipment Effectiveness (OEE).

Whether used for a single machine, a robotic workcell, a production line or an entire plant, OEE identifies the percentage of manufacturing time that is truly productive. A dimensionless parameter, OEE entails the multiplication of three factors:

Availability

A measure of machine uptime, this calculation takes actual operating time (planned production time minus stop time) and divides it by planned production time (shift time minus breaks).

Performance

A measure of system speed, this factor accounts for losses from running too slowly. This calculation can be achieved in several ways, but typically multiplies the total pieces produced by the ideal cycle time, then divides the product by the actual operating time.

Quality

A measure of part defects or losses due to poor quality, this calculation takes good pieces (pieces produced minus rejected pieces) and divides it by the total pieces produced.

When used properly, measuring OEE (OEE = Availability x Performance x Quality) provides a deeper insight into current operations. The ability to calculate it can help eliminate waste, as well as benchmark the production process for continuous improvement efforts, leading to greater ROI.

Implement Extensible Machine Monitoring

Implement Extensible Machine Monitoring

Thanks to Industry 4.0, smart factories peppered with robots and advanced technologies are taking shape, providing the ability to adapt to ever-changing demands faster than ever. To maintain the peak performance required for these networked production environments, as well as achieve greater OEE, savvy manufacturers are turning to factory automation monitoring systems to better track, accumulate and visually deliver data in real time.

Edge Server systems, like Yaskawa Cockpit™, are extensible and can support multiple brand devices via Add-on Functions, enabling an integrated, intelligent and innovative approach that allows manufacturers to see what is happening at any point on the value creation chain. In turn, this facilitates data-driven optimized planning for preventative and predictive maintenance, prompting proactive decisions for more productive and profitable factories.

Take a Security-first Approach

While having all devices on a network has its advantages where remote access and data collection are concerned, the interconnectedness of this equipment can put manufacturers at greater risk for cyber-attacks. Hacking and viruses are all too common and often result in costly production stoppage, data loss, data theft or even device failure.

To avoid these detrimental outcomes, company leaders should put security at the forefront, weighing the various options available. A handful of manufacturers may choose to keep devices off the internet completely, while other may implement network isolation via a Virtual Private Network (VPN) that requires some level of authentication such as Multi-Factor Authentication (MFA). Organizations like research institutes or manufacturers with protected intellectual properties may utilize an adaptive firewall with Artificial Intelligence (AI) that can detect and defend a robot against external connections. No matter the method, constant monitoring of an industrial network by IT staff is paramount, and any vulnerability must be addressed or patched as quickly as possible to maintain security and safety for ultimate ROI.

Foster Digital Skills

Foster Digital Skills

The shocking truth for many manufacturers today is that for smart factories to reach their full potential, it requires a skilled human component. Industry 4.0 has caused a technological shift, changing the primary capabilities needed to fulfill many industrial tasks. Similarly, as digitization and robotic automation continue to permeate the industrial landscape, there will continue to be a dichotomy between existing worker skills sets and the knowledge needed to operate advanced technologies.

To push forward and achieve the greatest return on investment with these tools, manufacturers should be proactive and create a talent pipeline more in-line with the skills required for future success.

Most likely, this will entail company leaders to invest in their current workforce by providing adequate industrial education opportunities, as well as incentivizing motivated employees to learn the necessary skills for tasks like robot programming and maintenance. It may also include hiring new talent altogether.

Robots can be a great investment, often providing energy savings, greater flexibility, increased quality and high-speed production, but complete operational success and subsequent ROI go far beyond implementing cutting-edge solutions. To build strong competitive advantages and enduring leadership in their respective industries and markets, manufacturers should stay the course by following a strategic plan, harnessing valuable data and procuring expert support. Not only will this make boosting productivity more manageable, but it will foster long-term return investment for years to come.