EVCO Plastics is a global injection molder based in DeForest, Wisconsin, with plants throughout the USA as well as Mexico and China. Since 1948, the company has produced parts for myriad industries, including powered sports equipment, lawn & garden devices, agricultural and construction machinery, appliances and plumbing fixtures, plus medical and packaging machinery, general industrial products, and more.

With over 150 presses in the 28-3500 ton range, its own mold production, and a world-class metrology lab for quality evaluation, EVCO brings a powerful asset to its expanding global customer base.

The company performs ISO Class 8 Cleanroom, large part, thin-walled, metal-to-plastic insert, gas-assist, multi-shot and overmolding operations, plus in-mold decorating and labeling in highly automated and robotic facilities. EVCO produces parts in various thermoplastic materials, ranging from basic polypropylene to engineering-grade materials. The company currently employs over 1000 people at its nine locations worldwide and is a major player in the global injection molding arena.

The company performs ISO Class 8 Cleanroom, large part, thin-walled, metal-to-plastic insert, gas-assist, multi-shot and overmolding operations, plus in-mold decorating and labeling in highly automated and robotic facilities. EVCO produces parts in various thermoplastic materials, ranging from basic polypropylene to engineering-grade materials. The company currently employs over 1000 people at its nine locations worldwide and is a major player in the global injection molding arena.

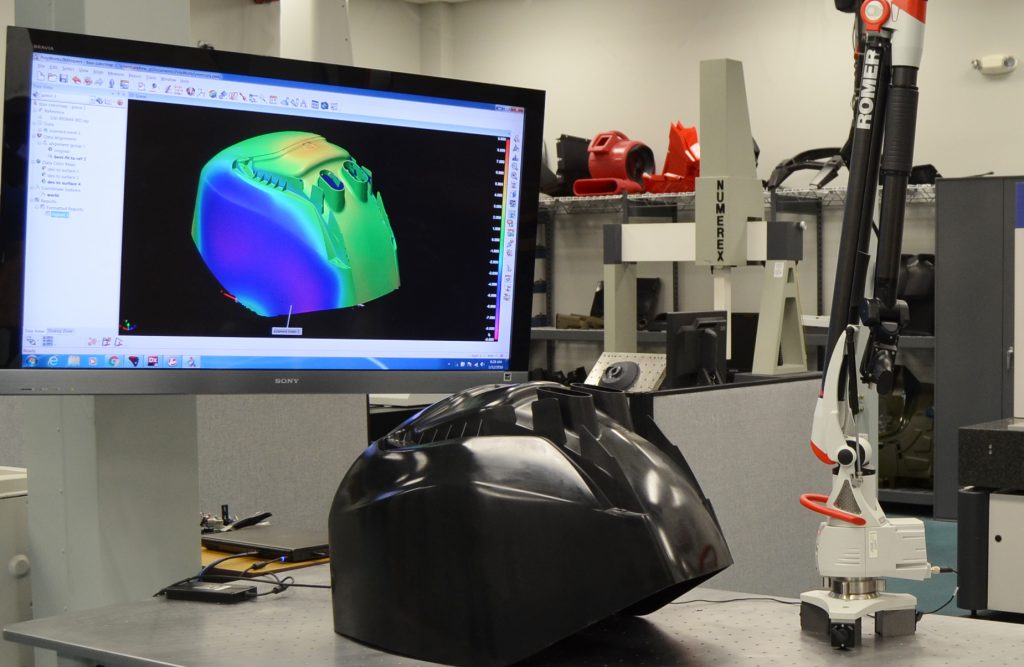

Part of the EVCO strategy, according to the head of the metrology lab Rich Duval, is “to have the ability to take apart, scan it, compare it to the CAD/CAM files, as early as possible in the process and to allow the customer to observe how the plastic product compares to the solid model. Duval also notes that by using scanning technology and reverse engineering, the EVCO metrology team has been able to recreate the surface of tooling where solid models don’t exist and provide this data to a tool shop for steel revisions.

Recently, owing to the volume of work coupled with the challenges of collecting and processing point cloud data in the lab, the EVCO team turned to its supplier partner, Exact Metrology (Brookfield, Wisconsin) for assistance. The company had been researching earlier generation scanning but saw more advanced Romer and other brands of scanning arms in the Exact product offering. Exact is a dual-purpose vendor, as it both sells metrology equipment and also performs very complex scanning services for customers, including use of the first industrial-grade CT scanner in America, which enables geometric views inside molded, cast and forged parts to check for porosity, hot spot, and material flow issues.

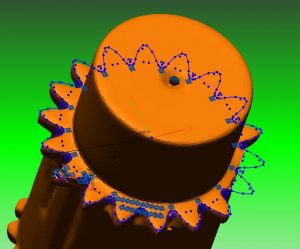

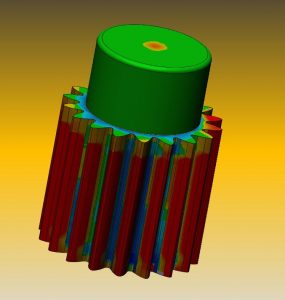

Exact VP Dean Solberg and his team of metrology technicians and application support specialists reviewed the EVCO scenario and provided several new Romer arms to its customer. One example involved the staff taking a damaged tool component and reconstructing the cogs on a machine gear. Once rechecked through design, a suitable alternative could be 3D printed. In this way, notes Duval, the metrology solution proposed by Exact has reduced inspection time in the lab and provided reverse engineering as an additional option to customers.

Exact VP Dean Solberg and his team of metrology technicians and application support specialists reviewed the EVCO scenario and provided several new Romer arms to its customer. One example involved the staff taking a damaged tool component and reconstructing the cogs on a machine gear. Once rechecked through design, a suitable alternative could be 3D printed. In this way, notes Duval, the metrology solution proposed by Exact has reduced inspection time in the lab and provided reverse engineering as an additional option to customers.

Similarly, older molds used at EVCO are being evaluated with the scanning techniques for the position of runners, pins, cores, and other components. A solid model is produced from the scans to show auto-surfacing, solid model processing, and solid model in-use characteristics. Often, reverse engineering from existing parts is also performed in the EVCO lab for production issue resolution or part validation.

While EVCO continues to use the conventional CMM technology in its metrology department, Duval notes his team of technicians has been able to “marry” the Romer arm and CMM technologies. Dean Solberg from Exact adds, “This was possible, only because of the talent on the team at EVCO.” In practice, the combination of the 3D scans with the bridge CMM plates gives the EVCO technicians and design engineers the necessary comparative data to resolve any issues that arise.

While EVCO continues to use the conventional CMM technology in its metrology department, Duval notes his team of technicians has been able to “marry” the Romer arm and CMM technologies. Dean Solberg from Exact adds, “This was possible, only because of the talent on the team at EVCO.” In practice, the combination of the 3D scans with the bridge CMM plates gives the EVCO technicians and design engineers the necessary comparative data to resolve any issues that arise.

Support from the Exact team has aided EVCO during this ramp-up of the new scanning technologies, according to Duval, who notes, “We had some lurking questions after the initial training session, but Dean was very pro-active and amended the training protocol to suit our specific requirements. It’s produced a very positive outcome here.”

As a supplier to major OEM’s in many industries, EVCO is routinely expected to supply considerable part and production data to its customers, according to Duval. “We are planning to utilize the Exact equipment to support tooling, as well, so there will be a seamless capture and transmission of data from part design through production here.

EVCO has also investigated further use of the Exact CT scanning services, though many of the very large parts produced, such as farm machinery housings, exceed the scan envelope of the CT equipment, presently.

One of the strongest abilities at EVCO is the company’s production of near-finish prototypes. These prototypes are often produced with conventional CNC machining or through the use of the rapidly expanding 3D printing technologies. At EVCO, fused deposition modeling (FDM), with and without carbon fiber, is performed. Here, too, the 3D scanning techniques supplied by Exact Metrology produce the necessary data files such as STL that can reside in the “point cloud” for use by these advanced 3D prototype production technologies. Millions of data points provide the 3D printing equipment all necessary information to produce highly accurate prototypes and concurrently anticipate challenges that might arise in the transition from design to tool to production, according to Duval, who notes the Exact team has continued its high level of service and pro-active suggestion to keep pace with the EVCO team’s expectations.

One of the strongest abilities at EVCO is the company’s production of near-finish prototypes. These prototypes are often produced with conventional CNC machining or through the use of the rapidly expanding 3D printing technologies. At EVCO, fused deposition modeling (FDM), with and without carbon fiber, is performed. Here, too, the 3D scanning techniques supplied by Exact Metrology produce the necessary data files such as STL that can reside in the “point cloud” for use by these advanced 3D prototype production technologies. Millions of data points provide the 3D printing equipment all necessary information to produce highly accurate prototypes and concurrently anticipate challenges that might arise in the transition from design to tool to production, according to Duval, who notes the Exact team has continued its high level of service and pro-active suggestion to keep pace with the EVCO team’s expectations.

The new metrology equipment used at EVCO is helping the company attain its stated goal of supplying world-class plastic products and assemblies.

About Exact Metrology

Exact Metrology, with facilities in Cincinnati, OH, Moline, IL, and Milwaukee, WI, and affiliated offices throughout the country is a comprehensive metrology services provider, offering customers 3D and CT scanning, reverse engineering, quality inspection, product development, and 2D drawings. The company also provides turnkey metrology solutions, including equipment sales and lease/rental arrangements. Exact Metrology offers a complete line of portable scanning and measurement technologies as well as contract measurement for 3D laser scanning services, reverse engineering services, non-contact inspection, metrology services, and 3D digitizing. The company’s newest equipment includes a CT Scanner, the first in America being used for metrology rather than medical testing. Exact sells and rents metrology equipment solutions, in addition to providing testing as a service and application software training.