What does the digital transformation in engineering mean and what role does the Eplan Project play in it? A decisive one, because digitization isn´t only relevant for a company´s back-end or commercial processes. It actually affects the entire product development process. The practical advantages are clear: Users can utilize the services of the Eplan Platform and tap into the added value of cloud-based services at the same time. The Eplan Platform allows data created in the used applications to be transferred to the cloud with the click of a mouse.

The central goal of digitization is optimizing processes, enhancing efficiency and thereby increasing the availability of machines and systems. The continued development of the Eplan Platform supports this process. In the engineering phase, the focus is on the digital twin of a control cabinet. The basis for this is high-quality 3D data that represent the housing and accessories that are supplemented with component and wiring information relevant to the Project. Data can be exported without any media disruption and used in other subprocesses such as manufacturing, including wiring. Interdisciplinary engineering also offers significant potential for optimization. This makes it possible to store information in a central location – in the Eplan Project – including saving parameter data of smart sensors, and using it in downstream processes.

AML as exchange format

Open, standardized interfaces, such as AutomationML (AML) for example, make this data available to any user without any application-specific formats or data structures. For instance, users could be machines for control cabinet processing or wire processing, or employees who are carrying out the wiring with the help of digital information. During the operating phase, the goal is to maximize system availability and to minimize downtimes in case of system failures. QR codes on installed components assist in finding them in the system and make their attributes – including part numbers and technical data for sourcing replacement parts – available anywhere in the systems and at any time via tablet or smartphone.

Collaboration explicitly welcome

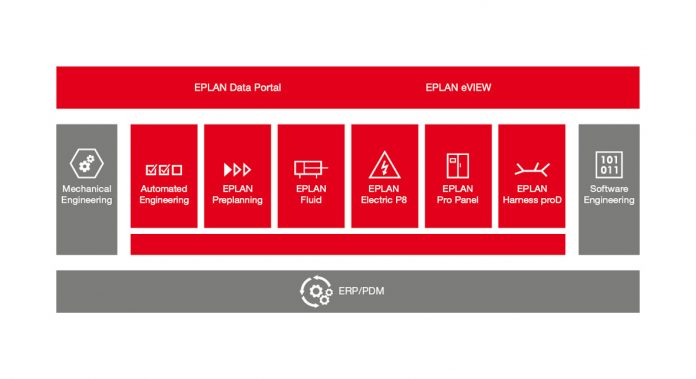

Eplan ePulse ideally supports these scenarios. If the above mentioned project data are saved there, nothing is standing in the way of accessing it at any time and from any location. The Eplan Platform utilizes this innovative approach by giving users the possibility to transfer data generated in the used applications to the cloud with just a mouse click. The Eplan Project can be shared in Eplan eView with the required partners for collaboration. Companies become networked with their customers and suppliers by making data exchange both easy and secure. The Project is thereby the central digital model of an automation solution that is built with various applications such as Eplan Electric P8, Eplan Pro Panel or Eplan Fluid and is available as the single source of truth. Ultimately, it provides the necessary data for all downstream processes.

Advantages and benefits

Users can take advantage of the benefits of the established Eplan Platform and at the same time tap into the added value of cloud-based services such as Eplan eView and Eplan Cogineer.

About EPLAN Software & Service

EPLAN provides software and service solutions in the fields of electrical, automation and mechatronic engineering. The company develops one of the world´s leading design software solutions for machine and panel builders. EPLAN is also the ideal partner to streamline challenging engineering processes.

Both standardized as well as customized interfaces to ERP and PLM/PDM systems ensure data consistency along the whole value chain. Working with EPLAN means boundless communication across all engineering disciplines. No matter whether small or large enterprises: Customers can apply their expertise more efficiently. EPLAN wants to grow further with customers and partners and pushes integration and automation in engineering forward. Worldwide, EPLAN supports over 55,000 customers. Efficient engineering» is the focus.

EPLAN was founded in 1984 and is part of the owner-operated Friedhelm Loh Group. The Friedhelm Loh Group operates worldwide with 18 production sites and 80 international subsidiaries. The entire group employs 12,000 people and generated revenues of around €2,6 billion in 2018. For the eleventh time in succession, the family business has won the accolade »Top German Employer» in 2019. In addition Friedhelm Loh Group was recognized as »Top vocational trainer» according to a study of Deutschland Test and Focus Money.

EPLAN Software & Services LLC

425 N. Martingale Rd., Suite 470

Schaumburg, IL 60173 USA

Contact

Debbie Raymundo

P: (847) 744-5729

F: (847) 240-4667